Hlau stamping

Cov lus piav qhia luv luv:

Hlau stamping yog siv punch thiab tuag kom deform lossis tawg ntawm cov hlau, hlau, txhuas, tooj liab thiab lwm cov phiaj thiab cov khoom txawv teb chaws kom ua tiav qee hom thiab qhov loj ntawm txheej txheem.

Cov txheej txheem stamping tuaj yeem muab faib ua cov txheej txheem sib cais thiab tsim cov txheej txheem (suav nrog khoov, kos thiab tsim). Cov txheej txheem sib cais yog cais cov stamping ib feem thiab qhov khoob raws qee qhov contour kab hauv cov txheej txheem stamping, thiab qhov zoo ntawm qhov sib cais ntawm cov tshooj stamping yuav tsum ua tau raws li qee yam; cov txheej txheem tsim yog ua kom lub stamping khoob yas deformation nyob rau hauv qhov xwm txheej ntawm tsis muaj kev puas tsuaj, thiab hloov nws mus rau hauv cov khoom tiav cov khoom uas xav tau, thiab tseem ua tau raws li cov kev xav tau ntawm kev sib npaug thiab lwm yam.

* Raws li cov ntawv kub stamping, muaj ob txoj hauv kev txias stamping thiab kub stamping. Qhov no nyob ntawm lub zog, plasticity, tuab, deformation degree thiab cuab yeej muaj peev xwm ntawm cov khoom, thiab lub qub kev kho cua sov lub xeev thiab kev pabcuam zaum kawg ntawm cov khoom yuav tsum raug txiav txim siab. 1. Txias stamping hlau ua nyob rau ntawm chav tsev kub, feem ntau siv rau tuab ntawm tsawg dua 4mm dawb paug. Nws muaj qhov zoo ntawm tsis muaj cua kub, tsis muaj tawv nqaij oxide, zoo nto zoo, haujlwm yooj yim thiab txo nqi. Qhov tsis zoo yog tias muaj kev ua haujlwm nyuaj ntawm qhov tshwm sim, uas ua rau cov hlau poob qhov muaj peev xwm txuas ntxiv. Cov tuab ntawm seem yog cov teeb thiab tsis muaj kos yog yuav tsum tau. 2. Kub stamping cov hlau yog rhuab mus rau tej yam kub. Qhov zoo yog tias nws tuaj yeem tshem tawm cov kev ntxhov siab sab hauv, tsis txhob ua haujlwm siab, ua kom cov khoom siv plasticity, txo deformation tsis kam thiab txo zog siv zog ntawm cov khoom siv

* Peb qhov tseem ceeb ntawm stamping qhov system ntau lawm: tuag, nias thiab ntawv hlau

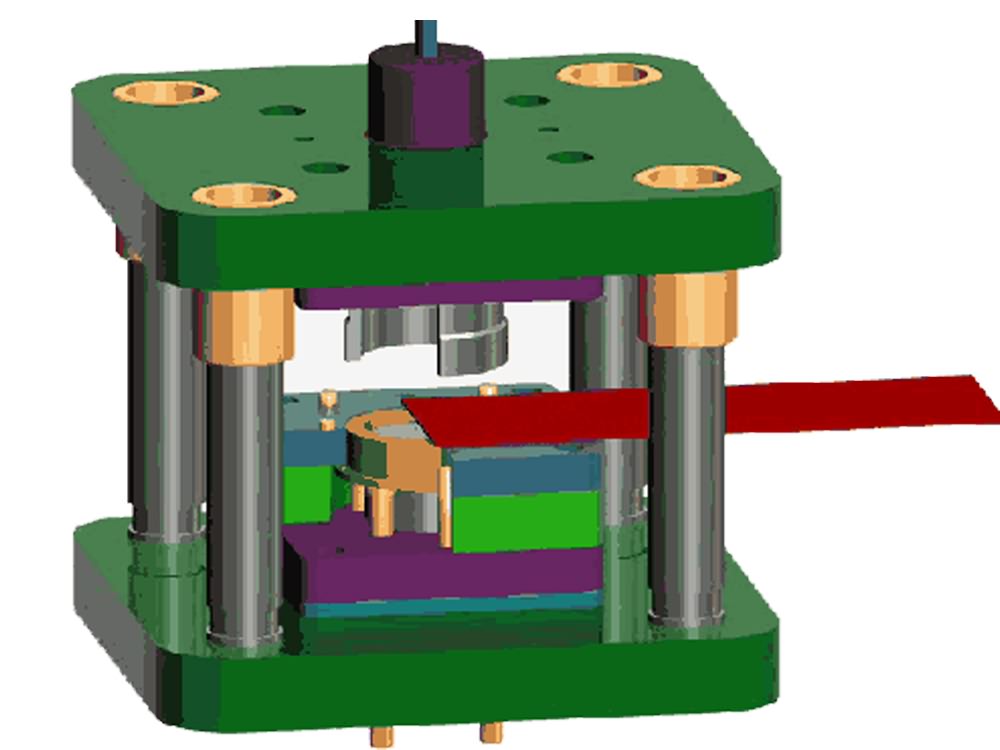

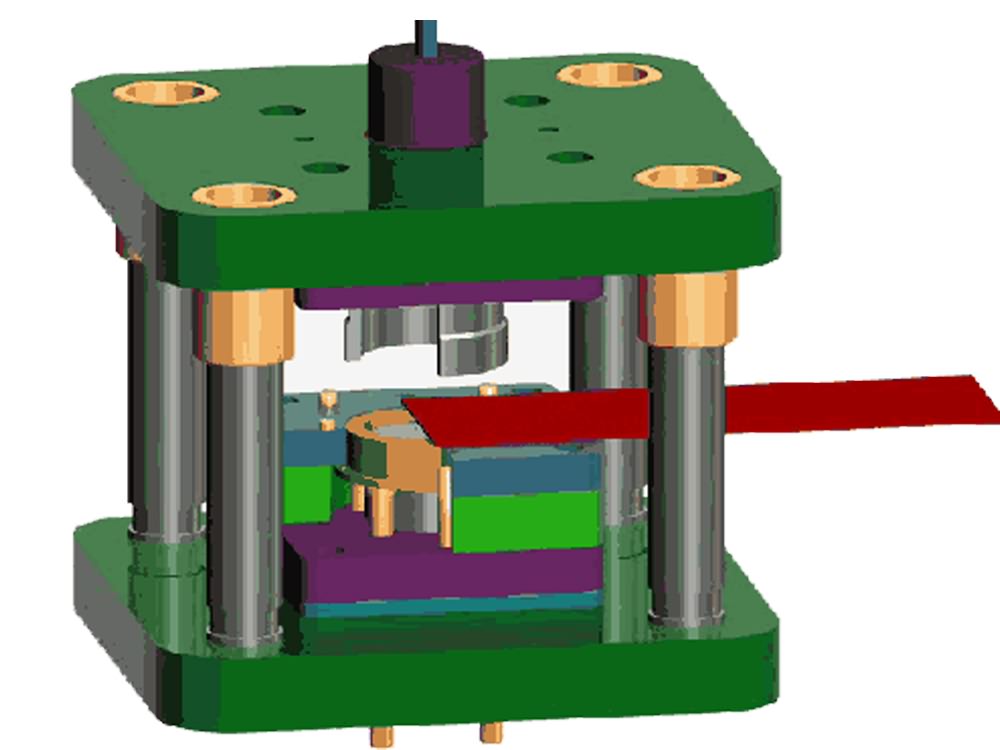

1. Punching Die Tuag yog qhov tuag tseem ceeb hauv stamping ntau lawm. Muaj peb hom stamping tuag: yooj yim tuag, tas li tuag thiab compound tuag.

Lub cev tuag yog qhov tuag tseem ceeb hauv stamping ntau lawm. Muaj peb hom stamping tuag: yooj yim tuag, tas li tuag thiab compound tuag.

(1) Tuag yooj yim: tuag yooj yim yog tuag uas tsuas yog ua tiav ib qho txheej txheem nyob rau hauv ib qho stroke ntawm cov xovxwm. Nws yog qhov tsim rau cov khoom siv me me ntawm cov khoom yooj yim.

(2) Kev tuag tsis tu ncua: nyob rau hauv ib qho kev sib tsoo ntawm cov xovxwm, tuag uas ua tiav ntau cov ntawv stamping ntawm ntau qhov chaw ntawm tus tuag thaum tib lub sijhawm yog hu ua tas li tuag. Kev tuag nruam yog tsim nyog rau kev ua haujlwm siab ntau lawm.

(3) Compound tuag: hauv mob stroke, hauv tib ntu tuag kom ua tiav ob peb lub stamping tib lub sijhawm, paub hu ua cov tuag. Compound tuag yog qhov haum rau stamping qhov chaw nrog cov zis loj thiab cov neeg siab.

2. Lub tshuab xuas nrig ntaus

Stamping ntau lawm yog feem ntau rau cov phaj. Los ntawm cov pwm, tuaj yeem ua rau viav vias, xuas nrig ntaus, tsim, kos duab, ua tiav, zoo nkauj nplaim, puab, riveting thiab extrusion qhov chaw, thiab lwm yam, siv dav hauv ntau qhov chaw. Piv txwv li, peb siv cov khoom siv hloov, cov khauj khiab, khob, khob khob, tais diav, khoom siv computer, txawm tias cov dav hlau tua hluav taws xob muaj ntau yam ntxiv uas tuaj yeem tsim nrog cov punch los ntawm pwm. Muaj ntau ntau hom kev xuas nrig ntaus cov tshuab.

(1) Lub zog ntaus tawm Cov neeg kho tshuab punch tau tsau mob stroke, kho tau ceev thiab cov khoom lag luam tsawg. Kev nrawm ntau 180 zaug / feeb.

(2) Cov xovxwm Hydraulic

Cov punch hydraulic tuaj yeem kho lub stamping stroke los ntawm hydraulic valve los txhim kho cov khoom lag luam. Qhov siab tshaj plaws yuav ncav cuag 1000 zaus / min. Qhov tsis zoo yog kev siv lub zog loj, kev xav tau ntawm ib puag ncig thiab lub luag haujlwm hnyav.

(3) Qhov kev siv raws li cov kev cai turret punch xovxwm

Kev siv servo lub cev muaj zog los tsav lub taub hau, qhov khoom lag luam siab, nce mus txog 800 zaug / min. Tsawg zog siv hluav taws xob, kev saib xyuas yooj yim thiab me me. Yog li ntawd, nws tau nquag siv.

Rau cov ntawv hlau zoo tib yam stamping, feem ntau ntawm lawv siv tshuab ntaus. Raws li cov kua sib txawv siv nyob rau hauv hydraulic presses, muaj hydraulic presses thiab hydraulic presses. Lawv feem ntau siv hydraulic xovxwm, thaum lub tshuab luam hydraulic feem ntau siv rau loj heev lossis tshuab tshwj xeeb. Vim tias nws cov txiaj ntsig zoo, servo motor punch raug siv ntau dua thiab ntau dua.

3. Cov ntaub ntawv stamping Cov khoom siv stamping ntawm feem yog phaj. Cov ntaub ntawv xaiv rau cov khoom tsim yuav tsum ua tau raws li kev ua haujlwm ntawm cov khoom, xws li kev nruj, kev khov kho thiab kev coj ua ntawm cov khoom. Ntawm qhov tod tes, nws yuav tsum ua kom tau raws li qhov yuav tsum tau ua ntawm plasticity, saum npoo zoo thiab tuab ntawm txheej txheem stamping. Cov qauv kev tsim ntawm cov ntawv stamping yuav tsum xav txog cov txheej txheem stamping cov txheej txheem, khoov vojvoog, muab tso rau qhov, teeb tsa, kos duab qhov tob, thiab lwm yam. thiab tsis deformation tsis kam, thiab tsim nyog rau txias stamping. (1). Ferrous hlau: SPCC / SPCD / spce, SECC / SECD / sece, SGCC, sgld, Sus (2). Aluminium alloy: al1050p, al1100p, al5020 (3). Tooj liab tooj: Pb phosphor bronze, HBS siab ua tau tooj dag (4). Cupro npib tsib xee alloy.

* Cov txheej txheem kev kho tshuab saum npoo ntawm cov khoom sib txawv Tom qab cov hlau pib ua tiav thiab cov duab, nws yuav tsum hloov kho cov hlau, ua kom zoo nkauj rau saum npoo, thiab ntxiv hloov cov khoom siv thiab lub cev thiab tshuaj ntawm cov hlau. Cov txheej txheem no yog hu ua kev kho saum npoo hlau. Lub hom phiaj ntawm kev kho hlau saum npoo tau muab faib ua plaub pawg:

(1) Zoo nkauj

(2) Kev Tiv Thaiv

(3) Cov cuab yeej tshwj xeeb saum npoo av

(4) Txhim kho cov khoom siv kho tshuab, xws li hnav tsis kam, lubricity, thiab lwm yam.

* Hom kev kho saum npoo Electroplating (zinc, tooj, npib tsib xee, chromium, kub, nyiaj), electrostatic txau, pleev xim rau xim, electrophoresis, silk screen luam ntawv, anodizing, blackening, passivation

* Sheet hlau stamping yog ib qho yooj yim kom ua tiav siab ntau lawm los ntawm kev siv tshuab thiab kev siv tshuab yooj yim kom paub txog kev siv tshuab thiab kev siv tshuab ua haujlwm nrog kev ua haujlwm siab; lub stamping qhov chaw muaj qhov loj me thiab kev sib hloov zoo; nplaim yog du thiab du, feem ntau tsis siv tshuab. Nws yog dav siv hauv tsheb, khoom siv hluav taws xob, twj paj nruag, aviation thiab lwm yam lag luam kev lag luam.

Mestech muab koj cov khoom siv hlau ntawm cov khoom lag luam thiab cov kev pabcuam. Yog tias koj muaj kev xav tau lossis xav paub ntxiv, thov hu rau peb.