Muab ob npaug rau-txhaj-molding-qhov

Cov lus piav qhia luv luv:

Tus ob chav txhaj tshuaj molding ntuyog cov txhaj tshuaj molding ib feem sof ob yam khoom sib txawv rau hauv tib txheej pwm, thiaj li paub qhov seem ua los ntawm ob hom khoom. Qee qhov ntawm ob cov ntaub ntawv sib txawv hauv cov xim, qee qhov sib txawv hauv kho vajtse thiab software, yog li txhawm rau txhim kho kev sib dhos thiab sib dhos ntawm cov khoom.

Ob chav txhaj tshuaj molding (Ntau cov ntaub ntawv txhaj tshuaj synchronous txhaj tshuaj) yog cov txheej txheem tseem ceeb moulding rau yas seem. Ob chav txhaj tshuaj muaj ntau qhov zoo nyob rau hauv cov txheej txheem, zoo, nqi thiab muaj txiaj ntsig. Tam sim no nws tau siv dav hauv yuav luag txhua qhov chaw yas, xws li khoom siv hluav taws xob, khoom siv fais fab, khoom siv kho mob, khoom siv hauv tsev, tsheb, khoom ua si, thiab lwm yam.

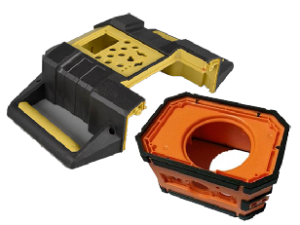

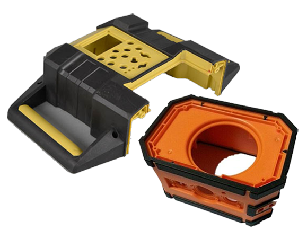

Ob chav txhaj tshuaj xuas tes ua

Ob chav txhaj tshuaj rau hauv tsev cov khoom siv hauv tsev

Ob chav txhaj tshuaj sib txuas khoom ntu

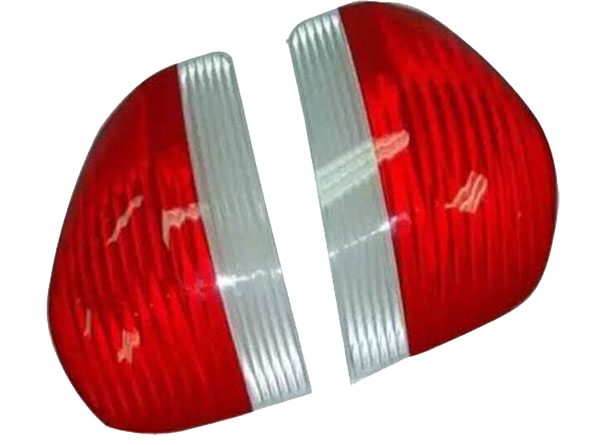

Pob tshab ob chav txhaj tshuaj lub tsheb teeb lub teeb

Muab ob npaug rau txhaj tshuaj ntaus khoom seem

Ob chav txhaj tshuaj yas rau cov khoom siv kho mob

1.Ob hom ntawm cov khoom siv sab hauv ob chav txhaj tshuaj moulded qhov muaj qhov zoo encapsulation: ob lub hnab yas khoom ua tiav nyob rau hauv kev txhaj tshuaj pwm tib lub voj voog txhaj tshuaj thiab tsis tas yuav xaiv tus kheej thiab muab tso rau hauv pwm. Piv nrog cladding lossis ntau tsoos cov txheej txheem nkag mus, nws muaj peev xwm txo ntau qhov tsis xws luag los ntawm kev ua tsis tiav.

2Cov. Cov khoom siv sab hauv ntawm kev txhaj tshuaj ob zaug txhaj tshuaj molding ua: kev sib xyaw kom zoo thiab txhim khu kev qha, nrog cov dej ua pov thawj zoo, hmoov av-pov thawj thiab khoom zoo.

3.Qhov kev txhaj tshuaj ob tog txhaj tshuaj tuaj yeem ua rau cov khoom siv ntawm ntau yam xim lossis cov qauv sib xyaw ua ke, ua rau cov khoom lag luam zoo nkauj dua thiab tshwj xeeb, thiab yeej qhov kev nyiam ntawm cov neeg siv khoom. thiab yuav muaj kev sis tw ntau hauv khw

4.Tom qab txhaj ob zaug txhaj tshuaj moulding, ob cov ntaub ntawv nrog qhov sib txawv hardness, kev ntxhib los mos lossis kev ua tau zoo tuaj yeem ua qhov sib txawv ntawm qhov chaw raws li kev xav tau, thiab kev ua tau zoo tshaj tuaj yeem tau txais. Xws li lub zog, rwb thaiv tsev, tuav kev xis thiab yooj.

5. Tom qab ob-txhaj moulding, ob cov ntaub ntawv uas nyuaj rau kev sib raug zoo los ntawm lwm cov txheej txheem tuaj yeem ua rau hauv kev ua tiav.

6. Qhov kev txhaj tshuaj ob tog txhaj yog tsim los ntawm cov khoom sib txawv rau hauv ib ntu ua ntej kom txo thiab zam qhov ua kom tsis haum thiab txuas ntxiv ntawm ntau qhov thiab txo tus nqi.

7. Peb muaj 7. Kev voj voog ntau lawm ntawm kev txhaj tshuaj moulding yog luv dua li ntawm lwm txoj kev txhaj tshuaj moulding, uas yog ib qho yooj yim kom paub cov tsis zoo no feem ntau lawm thiab kev ua haujlwm siab ntau lawm.

8. 8. Hauv kev siv ob npaug txhaj tshuaj txhaj tshuaj rau cov khoom siv, cov khoom siv tshwj xeeb nrog tus nqi siab tuaj yeem siv rau txheej txheem lossis cov tub ntxhais kom tau txais cov kev ua tau zoo tshwj xeeb, xws li kev tiv thaiv hluav taws xob cuam tshuam, kev coj zoo thiab lwm yam khoom siv los txhim kho kev ua haujlwm.

9. 9.Ob chav txhaj tshuaj txhaj yuav txais tau cov khoom sib txawv raws li kev siv cov yam ntxwv ntawm qhov sib txawv los txo cov nqi khoom. Piv txwv, cov khoom siv mos yog siv rau saum npoo ntawm cov khoom ua tiav tuab, cov khoom siv nyuaj yog siv rau cov khoom siv tseem ceeb kom tau raws li lub zog, los yog cov yas siv roj hmab yog siv rau cov khoom siv tseem ceeb kom txo qhov hnyav ntawm cov khoom.

10Cov. Cov khoom tseem ceeb ntawm kev txhaj tshuaj ob-koob txhaj tshuaj pwm tuaj yeem siv cov khoom siv viscosity tsawg los txo kev txhaj tshuaj thiab txo kev txhaj tshuaj nyuaj.

11Cov. Ob chav txhaj tshuaj txhaj rau hauv cov khoom haum rau kev txhim kho tib neeg lub cev engineering: tus kov lossis kov qhov chaw tuav los ntawm txhais tes yog ua los ntawm cov ntaub ntawv mos rau kev tuav tau yooj yim thiab ua haujlwm, yog li cov khoom tau txais tau zoo ib yam nrog tib neeg lub cev engineering. Qhov no yog qhov tshwj xeeb tshaj yog rau cov khoom siv kho mob thiab lwm yam khoom siv tuav.

12. 12s. Kev txhaj ob leeg txhaj tshuaj molding tuaj yeem ua ke nyuaj thiab mos polymers, thiab txawm tias cov khoom me me tuaj yeem muab kev nplij siab zoo thiab kev coj ua.

Mestech yog cov chaw tsim khoom yas dhau los uas tuaj yeem pab koj ua tiav tag nrho cov txheej txheem ntawm lub tswv yim mus rau cov khoom tiav, thiab xyuas kom meej los muab cov kev daws teeb meem zoo. Thov hu rau peb yog tias koj xav tau.