Machined qhov chaw

Cov lus piav qhia luv luv:

Machined qhov chawua qhov pib yooj yim ntawm ntau yam khoom siv cav thiab khoom siv. Cov cuab yeej siv thiab cov txheej txheem siv los ntawm nws ua ke ua tiav qib siab tshaj plaws ntawm kev siv tshuab tam sim no, cov ntaub ntawv, cov khoom sib tsoo, tshuab, khoom siv hluav taws xob, kev lag luam tswj thiab lwm cov teb.

Nrog rau kev txhim kho thev naus laus zis, qhov chaw muaj kuab thiab tshuab ua lub luag haujlwm tseem ceeb hauv kev lag luam niaj hnub. MESTECH tau muab rau cov neeg siv khoom lag luam kom paub meej cov hlau thiab qhov chaw tsis muaj hlau rau xyoo.

Dab tsi yog lub luag haujlwm ntawm precision hlau qhov chaw ua si hauv kev lag luam niaj hnub?

Tshuab cuab tam yog tus “Muaj niam tshuab” Cov. Yuav luag txhua yam khoom siv kho tshuab raug cais tawm ntawm kev siv tshuab tsis zoo. Nrog cov kev txhim kho tas mus li ntawm cov thev naus laus zis thiab cov cuab yeej siv, muaj qhov xav tau loj dua rau qhov chaw precision, xws li kev tsav dav hlau, chaw dav hlau, tsheb, kho mob, kev txawj ntse thiab cov tsim hluav taws xob, txhua yam yog cais los ntawm kev txhawb nqa ntawm precision seem. Yuav ua li cas kom ua tiav high-efficiency thiab tsawg tus nqi tsim ntawm precision qhov chaw yog teeb meem ntawm kev tsim tshuab kev lag luam.

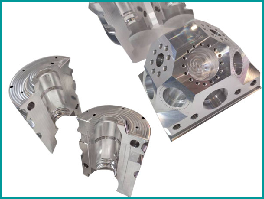

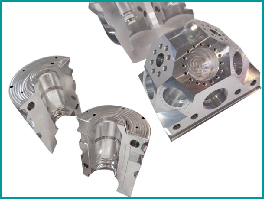

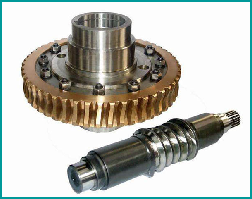

Hlau puag

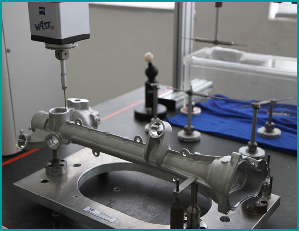

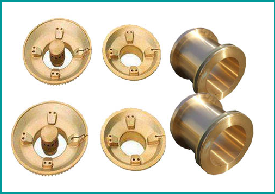

Cov cab iav

High precision qhov chaw

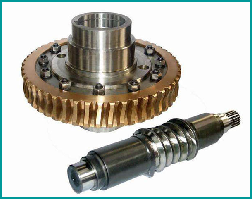

Nrig tooj daj

Koj paub ntau hom machining txheej txheem koj puas paub?

Precision machining yog txheej txheem ntawm kev hloov qhov loj lossis kev ua haujlwm ntawm kev ua haujlwm los ntawm kev siv lub tshuab ua khoom. Raws li qhov ntsuas kub ntawm lub xeev ntawm cov workpiece uas tau ua tiav, nws muaj peev xwm muab faib ua txias txias, kev ua haujlwm kub thiab tshwj xeeb kev ua haujlwm. Nws feem ntau ua tiav ntawm chav tsev kub thiab tsis ua rau muaj tshuaj lossis lub cev hloov ntawm lub workpiece. Nws yog hu ua kev ua haujlwm txias. Feem ntau, kev ua haujlwm nyob rau hauv lossis qis dua qhov kub thiab txias yuav ua rau hloov tshuaj lossis lub cev ntawm qhov chaw ua haujlwm, uas hu ua thermal ua haujlwm. Kev ua tiav txias tuaj yeem muab faib ua cov txiav thiab siab ua raws li qhov sib txawv ntawm cov txheej txheem ua. Kev kho cua sov, forging, nrum thiab vuam yog qhov tshwm sim hauv kev ua haujlwm kub. Precision txiav feem ntau yog qhov kawg ua tiav txuas kom paub tseeb qhov tseeb ntawm qhov chaw, thiab nws tseem yog qhov txuas nrog kev ua haujlwm ntau tshaj plaws, ua ntau tshaj 60% ntawm kev ua ntawm cov khoom siv tshuab.

Dab tsi yog precision tshuab txiav?

Kev txiav tshuab yog txoj kev tseem ceeb ntawm kev siv tshuab, xa mus rau cov txheej txheem ntawm kev tshem tawm cov khoom los ntawm kev siv lub tshuab npliag.

Precision mechanical txiav yog ib hom kev siv lub tshuab ua haujlwm siab. Muaj ob txoj kev tseem ceeb kom paub meej precision machining ntawm qhov chaw:

(1) Ib qho yog siv cov cuab yeej siv high-precision tshuab ua cov txheej txheem high-precision qhov chaw, xws li kev sib xyaw tho txawv tshuab, xov grinder, cab grinder, iav grinder, optical grinder, high-precision sab nraud grinder, high-precision hob grinder, siab -precision xov tshuab dhos, thiab lwm yam Cov cuab yeej siv tshuab no yog high-precision tshwj xeeb cov cuab yeej siv tshuab, tshwj xeeb yog siv rau kev ua cov khoom tshwj xeeb ntawm cov ntu, xws li lub zog, cov tshuab raj, ntsia hlau, cov cuab yeej txiav, high-precision kis ncej thiab lub thawv cav, thiab lwm yam Cov cuab yeej siv tshuab no tau ua haujlwm tau zoo thiab raug rau kev ua cov haujlwm tshwj xeeb.

(2) Qhov thib ob yog siv lub tshuab thev naus laus zis yuam kev txhawm rau txhim kho kev ua tiav ntawm qhov raug. Lub ntsiab lus tseem ceeb tswj kev siv lub tshuab yog CNC milling tshuab, CNC tshuab dhos, CNC grinder, CNC tho txawv thiab milling tshuab, thiab compound machining chaw.

CNC tshuab cov cuab yeej yog cov hom phiaj dav dav siv tshuab, vim tias kev siv lub koos pij tawj siv tshuab, tuaj yeem npaj ua ntej rau lub computer simulation ua thiab debugging, muaj kev sib raug zoo thiab yoog raws, haum rau cov qauv duab, ntau yam ntawm kev ua. Cov cuab yeej siv lub tshuab CNC yog kim, tab sis lawv tuaj yeem paub cov automation ntawm kev ua, thiab muaj cov rov ua dua zoo raug thiab cov txiaj ntsig kev tsim khoom.

Yuav ua li cas xaiv cov cuab yeej tsim nyog ua?

Nrog txoj kev loj hlob ntawm lub koos pij tawj tswj kev siv tshuab, ntau dua thiab ntau lub tshuab ua haujlwm tau ua ke nrog CNC system, txhawm rau kom paub txog kev siv hluav taws xob ua tiav, zam kev ua haujlwm yuam kev, thiab txhim kho kev ua haujlwm raug thiab ruaj khov. Yog li no, cov cuab yeej siv tshuab CNC yog dav siv hauv qhov tseeb ntawm qhov chaw tsim khoom.

(1) CNC ua kev ua haujlwm zoo ntawm cov ntawv hlau zoo yog siab, nrog kev ua haujlwm ruaj khov;

(2) Nws tuaj yeem nqa tawm ntau txoj kev sib txuas ua ke thiab ua cov txheej txheem ntu nrog cov duab tsis xwm yeem.

(3) Thaum CNC seem ntawm cov khoom siv zoo raug hloov pauv, tsuas yog NC tswj hwm txoj haujlwm yuav tsum tau hloov pauv kom txuag lub sijhawm npaj khoom.

(4) Lub tshuab cuab tam nws tus kheej muaj qhov siab thiab qhov nruj, thiab tuaj yeem xaiv qhov txiaj ntsig zoo rau kev ua, thiab cov txiaj ntsig cov khoom tso tawm yog siab (feem ntau 3 txog 5 npaug ntawm qhov ntawd ntawm lub tshuab cuab yeej dav dav).

(5) Cov cuab yeej siv tshuab yog tshuab tau zoo heev thiab tuaj yeem txo qhov kev siv dag zog.

CNC ua haujlwm zoo siv cov cuab yeej luv luv yog lub ntsiab tseem ceeb ntawm cov khoom siv ua tau zoo. Cov ntawv txiav luv luv tuaj yeem txo cov cuab yeej sib txawv, thiab tom qab ntawd ua tiav cov khoom zoo tshaj plaws hauv pem teb, tsis txhob rov ua haujlwm dua, txo kev siv vuam siv, thiab ua kom lub sijhawm EDM ua tiav. Thaum xav txog tsib-axis machining, nws yog qhov yuav tsum txiav txim siab txoj ntsiab cai ntawm kev siv tsib-axis ua kev tuag: txhawm rau ua kom tag nrho cov txheej txheem ua haujlwm nrog cov khoom txiav luv tshaj plaws kom deb li sai tau, tab sis kuj yuav txo qhov program, clamping thiab kev siv sijhawm kom tau ntau zoo tshaj plaws zoo deg.

Yuav ua li cas ua rau kev siv tshuab tsim nyog?

(1) tsis tshua muaj neeg ua theem. Txhawm rau txiav feem ntau ntawm cov nyiaj ua tiav ntawm txhua cov txheej txheem ua kom tiav thiab los ua tus qauv raug ntsuas, qhov kev txiav txim siab tseem ceeb tshaj plaws yog txhim kho cov khoom lag luam kom ntau li ntau tau.

(2) Kev ua tiav ib qib. Tshem tawm qhov tsis txaus uas tshwm sim tom qab ua haujlwm ntxhib, npaj rau qhov ua tiav ntawm qhov zoo li, xav kom mus txog qhov ua tiav cov txheej txheem, ua kom tiav qhov tsim nyog tau ua kom tiav, thiab ua tiav qib ob txheej txheem ua ke.

(3) Cov theem tiav. Nyob rau qib no, kev txiav loj dua, pub me me thiab txiav qhov tob raug xaiv kom raug tshem tawm cov nyiaj ua tiav dhau los ntawm cov txheej txheem dhau los thiaj li ua kom pom cov seem ntawm cov seem ua tau raws li cov kev xav tau ntawm cov duab kos.

(4) Ultrafine machining theem. Nws yog tsuas yog siv los txo tus nqi ntawm saum npoo los yog ua kom muaj zog hauv kev ua cov duab. Nws yog tsuas yog siv rau kev ua cov txheej txheem nrog cov siab xav tau ntawm qhov kev ntxhib los mos saum npoo (ra <0.32 um).

(5) Ultra-zoo ua theem. Machining qhov tseeb yog 0.1-0.01 micron thiab sab saum npoo roughness tus nqi RA yog tsawg dua 0.001 micron. Cov txheej txheem tseem ceeb yog: kev txiav kom zoo, daim iav kev sib tsoo, kev sib tsoo zoo thiab polishing.

Yuav ua li cas xaiv cov khoom haum rau qhov workpiece?

Kev ua tiav ua ntej, tsis yog txhua yam ntaub ntawv raw tuaj yeem xav ua qhov ua tiav precision, qee cov ntaub ntawv raw kuj nyuaj dhau, dhau qhov nyuaj ntawm kev siv lub tshuab ua khoom, tej zaum yuav ua rau lub tshuab qhov chaw tawg, yog li cov khoom siv raw no tsis haum rau cov neeg siv khoom precision, tshwj tsis yog nws yog tsim cov khoom siv tshwj xeeb, lossis laser txiav.

Cov ntaub ntawv raw khoom rau kev ua haujlwm siab yuav tau muab faib ua ob pawg, cov khoom siv hlau ua raw khoom thiab cov khoom siv hlau tsis yog hlau.

Raws li rau cov ntaub ntawv hlau, cov tawv tawv ntawm xeb hlau yog siab dua, ua raws li cov cam khwb cia hlau, ua raws li tooj liab thiab softer txhuas.

Kev ua cov ntoo thiab cov plastics ua rau ntawm kev ua cov khoom siv tsis yog xim hlau.

1. Ua ntej tshaj plaws, ntu yuav tsum muaj qee qib tawv. Rau qee daim ntawv thov, lub siab dua qhov nyuaj ntawm cov khoom dawb, zoo dua. Nws tsuas yog txwv rau qhov ua kom nyuaj ntawm cov khoom machined. Cov ntaub ntawv machined tsis tuaj yeem ua nyuaj. Yog tias lawv cov cav hnyav dua li cov ntu machined, lawv tsis tuaj yeem ua cov tshuab.

2. Thib ob, cov khoom siv yog sim hauv hardness thiab softness. Tsawg kawg ib theem ntawm qhov nyuaj yog qis dua qhov ntawm lub tshuab ntu. Nyob rau tib lub sijhawm, nws nyob ntawm qhov ua haujlwm ntawm cov txheej txheem ua haujlwm thiab kev xaiv kom raug ntawm cov ntaub ntawv rau lub tshuab qhov.

Hauv qhov luv luv, tseem muaj qee qhov yuav tsum tau ua rau cov khoom zoo hauv qhov tseeb ntawm lub tshuab, tsis yog txhua cov ntaub ntawv tsim nyog rau kev ua, xws li cov khoom muag muag lossis tawv tawv, qhov qub tsis tsim nyog rau kev ua, thiab tom kawg tsis tuaj yeem ua txheej txheem.

Mestech muab cov neeg siv khoom lag luam nrog kev tsim khoom thiab kev ua tiav ntawm cov nplais qhov chaw hlau. Yog tias koj xav tau cov ntaub ntawv ntxiv, thov hu rau peb.