Tuag casting txheej txheem

Cov lus piav qhia luv luv:

Tuag casting txheej txheem yog cov txheej txheem nyob rau hauv uas zinc, tooj liab, txhuas, magnesium, txhuas, tin thiab txhuas tin alloys thiab lawv cov alloys yog yaj ntawm qhov kub thiab txhaj rau hauv cov pwm kab noj hniav, thiab tom qab ntawd txias txias nyob hauv siab kom tau txais cov ntu.

Kev ua haujlwm kub ntawm cov hlau tsis muaj hlau tuag casting yog ntau tsawg dua li ntawm cov hlau nrum, thiab cov khoom siv sib piv thiab cov txheej txheem yuav tsum yooj yim, thiab me me. Die casting ntau lawm tuaj yeem tau txais cov khoom zoo heev hauv qhov chaw zoo thiab qhov loj me, qhov tshwj xeeb tshaj yog tsim rau kev lag luam loj cov qauv ntawm qhov chaw me thiab nruab nrab, uas muab cov kev txhawb nqa zoo rau cov khoom siv hluav taws xob niaj hnub, khoom siv hluav taws xob, tsheb, khoom siv kho mob, twj paj nruag thiab khoom siv twj. Cov hlau hlau sib txawv muaj ntau tus cwj pwm sib txawv hauv cov txheej txheem tuag casting. Lawv qhov seem tsawg kawg thiab kev sib cais yam tsawg kawg yog txawv, yaj taw tes qhov kub yog qhov sib txawv, qhov chaw ua tiav yog qhov sib txawv, Yog li nws yog qhov zoo tshaj plaws kom koom nrog peb pab pawg ntawm cov engineers thaum ntxov thaum lub sijhawm tsim qauv los siv peb cov kev txawj ntse nrog kev tsim qauv tsim khoom.

Muaj tsib lub hauv paus tseem ceeb hauv cov hlau tuag casting txheej txheem:

1.Die cov khoom siv casting;

2.Txiav ntawm kev tuag casting txheej txheem;

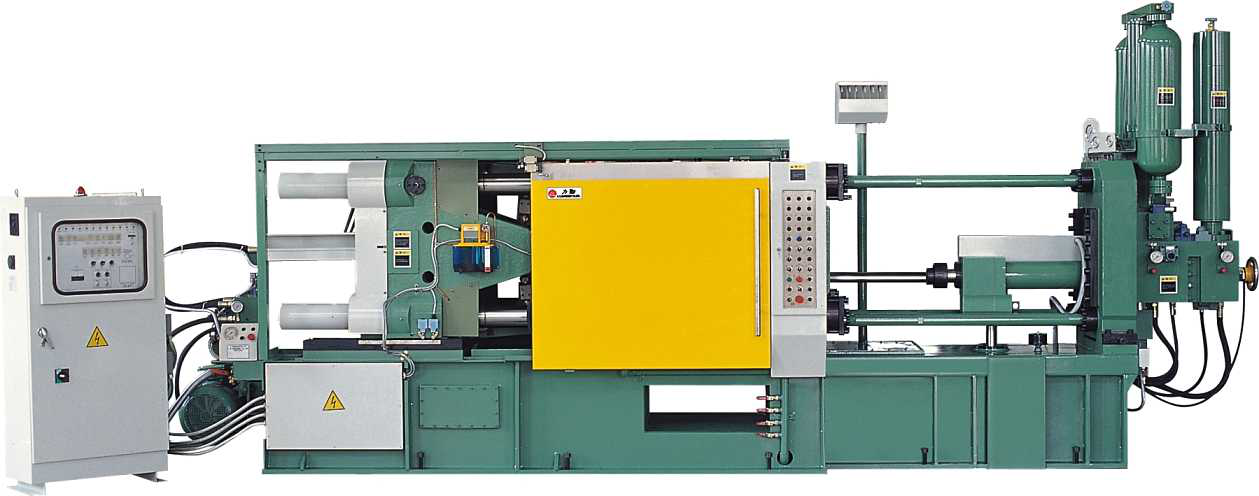

3.Die casting tshuab;

4.Die casting pwm;

5.Txoj kev ua kom tiav thiab ua tiav rau Tuag Casting Qhov Chaw

Hlau tuag casting txheej txheemyog txheej txheem ntawm kev sib koom ua ke ntawm lub siab, ceev thiab lub sijhawm los ntawm kev siv peb yam ntawm tshuab, pwm thiab alloy. Rau cov hlau ua haujlwm kub, qhov muaj nyob ntawm lub siab yog lub cim tseem ceeb ntawm kev tuag casting cov txheej txheem uas txawv ntawm lwm txoj kev casting. Lub siab casting yog qhov tshwj xeeb casting txheej txheem nrog tsawg dua thiab tsis txiav, uas tau tsim kho sai ntawm cov hlau ua niaj hnub siv tshuab. Nws yog txheej txheem ntawm kev sau pwm nrog molten hlau nyob rau hauv kev kub siab thiab kev kub ceev, thiab sib sau lub casting los ntawm crystallization thiab solidification hauv qab cov siab. Ua haujlwm siab thiab siab nrawm yog cov yam ntxwv tseem ceeb ntawm kev tuag casting. Feem ntau lub siab siv dav yog kaum ntawm megapascals, sau nrawm (sab hauv lub rooj vag ceev) yog txog 16-80m / s, thiab lub sijhawm sau ntawm cov kua hlau ua rau pwm kab noj hniav yog qhov luv heev, txog 0.01-0.2s. Hlau tuag casting yog txheej txheem hlau casting uas yog tus yam ntxwv los ntawm yuam cov hlau tsis muaj hlau hauv qab qhov siab rau cov pwm kab noj hniav. Cov pwm kab noj hniav thiab cov tub ntxhais ua tau siv cov tawv tawv tuag uas tau tsim rau cov duab thiab ua haujlwm zoo ib yam li txhaj tshuaj pwm thaum lub sijhawm ua. Ua raws li hom hlau raug nrum, lub tshuab kub-lossis txias txias siv.

1.Die casting materialMESTECH muab cov khoom tuag casting rau zinc alloy, aluminium alloy thiab magnesium alloy. Vim tias peb cov ntaub ntawv no yog qhov feem ntau siv tuag casting alloy cov ntaub ntawv ntawm tam sim no.

Zinc alloy cov yam ntxwv:

--- Muaj lub zog thiab tawv tawv

--- Kev lag luam zoo hluav taws xob

--- Cov ua haujlwm siab thermal

--- Tsawg tus nqi raw khoom

--- High dimension raug thiab ruaj khov

--- Zoo heev muaj peev txheej phab ntsa

--- Muaj peev xwm ua rau daim ntawv txias, uas eases koom

--- Zoo kawg nkaus cov yam ntxwv ua tiav

--- Txhim kho tsis kam corrosion --- Tag nrho cov khoom siv tau dua tshiab

2.Aluminium Alloy cov yam ntxwv:

--- Kev ua haujlwm siab kub

--- Muaj tsis kam tiv thaiv corrosion

--- Hnav me

--- Zoo heev lub zog thiab tawv

--- Zoo nruj thiab lub zog-rau-hnyav piv

--- Cov khoom zoo EMI thiab RFI shielding zog

--- Zoo thermal conductivity

--- Muaj hluav taws xob hluav taws xob zoo

--- Cov khoom tiav zoo

--- Kev siv lub thawv rov qab tag nrho

3. Magnesium Alloy Cov Cwj Pwm:

--- Siab conductivity; hluav taws xob, thiab cua sov

--- Tswj siab kev ua haujlwm siab kub

--- High dimension raug thiab ruaj khov

--- Qhov tshwj xeeb pliag nyias ntsa muaj peev xwm

--- Zoo ib puag ncig corrosion tsis kam

--- Cov khoom tiav zoo

--- Kev siv lub thawv rov qab tag nrho

1 Cov Txheej Txheem Ua Haujlwm Kub-Lub Cev Tuag Ua Haujlwm

Kub-casting tuag casting, qee zaum hu ua gooseneck casting, yog qhov nrov tshaj plaws ntawm ob qhov tuag casting txheej txheem. Nyob rau hauv txoj kev no, lub tog raj kheej ua haujlwm ntawm lub tshuab txhaj tshuaj yog kiag li raus hauv cov hlau molten da dej. Ib qho gooseneck hlau pub tsim tshuab rub cov hlau xaim hlau rau hauv cov kab noj hniav uas tuag.

Thaum ncaj qha kev sib xyaw rau hauv tus da dej molten tso cai rau kev txhaj tshuaj pwm sai thiab yooj yim, nws kuj tseem ua rau muaj kev cuam tshuam tsis muaj zog corrosion. Vim qhov tseeb no, qhov kub-chamber tuag casting txheej txheem yog qhov zoo tshaj plaws rau cov ntawv thov uas siv cov khoom siv hlau nrog cov ntsiab lus melting thiab siab fluidity. Cov hlau zoo rau qhov kub-chamber tuag casting txheej txheem suav nrog cov hlau lead, magnesium, zinc thiab tooj.

2 Tus Txheej Txheem Tus Txheej Txheem Ua Tuag Casting Txheej Txheem

Qhov txias-chamber tuag casting txheej txheem yog zoo heev rau kub-chamber tuag casting. Nrog tus qauv tsim tsom tsom rau kev siv tshuab ua kom tsawg dua li kev ua hauj lwm ntau lawm, cov hlau yaj yuav cia li- lossis siv tau tes mus rau hauv qhov chaw txhaj tshuaj. Qhov no tshem tawm qhov tsim nyog rau kev txhaj tshuaj tiv thaiv kom muab tso rau hauv molten hlau da dej.

Rau cov ntawv thov uas ib yam nkaus thiab xeb rau kev tsim cov qauv tsim lub ntsej muag kub tuag casting, txheej txheem txias txias txheej txheem tuaj yeem ua qhov zoo tshaj plaws. Cov ntawv thov suav nrog kev nrum hlau nrog kub siab melting, xws li txhuas thiab txhuas alloys.

3 Tus Txheej Txheem Ua Phem Siab Tuag Txoj Kev Tuag Casting

Tsawg-tuag tuag casting yog txheej txheem zoo tshaj plaws rau txhuas cov khoom sib xyaw uas zoo ib yam ntawm ib ncig ntawm kev sib hloov. Lub log tsheb, piv txwv li, feem ntau yog kev sib tw los ntawm kev tuag lub zog qis. Nyob rau hauv hom txheej txheem no, cov pwm nyob hauv txoj kab saum toj cov hlau tsis muaj hlau da dej thiab txuas nrog ntawm lub raj riser. Thaum cov cua ntsawj ntsiag to (feem ntau nruab nrab ntawm 20 txog 100kPa), cov hlau rub tawm sab hauv thiab nkag rau hauv cov pwm. Kev tshem tawm cov pub tawm los ntawm hom kev tuag casting txheej txheem no muab cov tseev kom zoo.

4 Kev Nqus Plua Plav Tuag Ua Cov Txheej Txheem

Lub tshuab nqus tsev siab casting (VPC) yog tus txheej txheem tshiab tuag casting uas muab cov khoom siv kom muaj zog thiab muaj kev coj ua kom tsawg. Cov txheej txheem no zoo ib yam li cov phiajcim tuag tsawg dua, tshwj tsis yog qhov chaw ntawm qhov tuag tuag pwm thiab molten hlau da dej tau rov ua dua. Lub tog raj kheej muaj peev xwm dhau los ua lub tshuab nqus tsev, uas yuam cov hlau yaj hlau mus rau hauv cov kab noj hniav pwm. Txoj kev tsim qauv no txo txoj kev nrawm thiab txwv ntawm cov roj suav nrog kom tsawg. Lub tshuab nqus tsev tuag casting yog tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov destined rau kev kho cua sov tom qab-casting.

5 Kev Caws Tus Txheej Txheem Ua Haujlwm Casting

Zuaj casting tau tsim raws li kev daws teeb meem ua haujlwm rau cov hlau nrum thiab alloys nrog qis npliag. Nyob rau hauv txoj kev no, cov hlau tsis muaj hlau fills li qhib kev tuag, uas tom qab ntawd nyem cov ntaub ntawv kaw, yuam cov hlau rau hauv cov ntu ntu ntawm kev txhaj tshuaj. Cov txheej txheem nyem txheej txheem muab cov khoom ntom ntom ntau heev thiab yog cov txheej txheem ntxiv rau tom qab kev kho cua sov. Cov txheej txheem feem ntau cuam tshuam nrog molten txhuas, thiab yog siv rau hauv cov ntawv thov uas hu rau fiber ntau ntxiv.

6 Tus Txheej Txheem Semi-Solid Die Casting Txheej Txheem

Semi-solid tuag casting, qee zaum hu ua Thixoforming, yog lwm cov txheej txheem uas xa me me porosity thiab qhov ntom ntom qhov siab tshaj plaws. Lub tshuab txiav cov haujlwm ua haujlwm rau hauv cov ntawv me, thiab tom qab ntawd kho kom sov. Thaum cov hlau tau nce mus rau theem hloov ntawm cov khoom thiab kua, uas ua rau muaj qhov ntxhib ntxoo me ntsis, rab koob txhaj tshuaj tiv thaiv nws nkag rau hauv cov pwm kab noj hniav, qhov twg nws tawv. Qhov txiaj ntsig ntawm qhov no yog kev txhim kho qhov tseeb. Cov hlau tsis muaj hlau xws li magnesium alloy thiab txhuas alloy yog feem ntau siv nrog cov semi-solid tuag casting txheej txheem.

7.Txiav ntawm kev tuag casting txheej txheem

Txhua txoj kev tuag casting cov txheej txheem tsim tau nrog tib lub hom phiaj hauv siab-nrum pwm siv kev txhaj tshuaj molten hlau. Ua raws li hom ntawm melted hlau, ib feem geometry thiab ib feem loj, txawv tuag txheej txheem txheej txheem tuaj yeem xa cov txiaj ntsig zoo dua li lwm txoj hauv kev. Ob lub ntsiab hom kev tuag casting txheej txheem yog chav tso cua sov thiab chav tsev txias tuag casting. Cov kev hloov ntawm ob hom kev tuag no suav nrog:

Tsawg-tuag tuag casting

Lub tshuab nqus tsev tuag casting

Zaws tuag casting

Semi-tau tuag casting

1 Kub siab chamber tuag casting tshuab

Raws li cov qauv thiab txheej ntawm chav, nws tuaj yeem faib ua cov qauv kab rov tav thiab ntsug. Lub crucible rau molten hlau txuas rau hauv tshuab los ntawm kub nias chav, thiab lub tshuab piston rau hlau hydraulic siab nkag mus rau hauv cov pwm raug ntsia hauv qhov crucible. Qee qhov kub nias lub tshuab ua cua tuag siv lub tshuab cua ntsaws ntsaws ncaj qha los txhaj cov hlau hydraulic siab rau hauv cov pwm tsis muaj qhov haujlwm piston.

Kub chamber tuag casting tshuab

Lub tshuab kub nias chamber tuag casting tshuab yog tsuas yog siv rau tuag-casting alloy nrog tsawg melting point, xws li zinc, Magnesium thiab tin.

2 Txias siab ua cua sov chamber tuag tshuab

Melting cov hlau nyob sab nraum lub tshuab thiab tom qab ntawd ntxiv cov kua hlau ua kua rau hauv chav tsev compression nrog ib rab diav tau muab faib ua ntsug txias chav ua haujlwm tuag casting tshuab thiab kab rov tav txias chamber tuag casting tshuab raws li cov kev taw qhia ntawm kev txav ntawm lub compression piston.

Lub tshuab ua kua hlau yog tshem tawm los ntawm lub tshuab ua kom sov cov ntsug txias xovxwm chamber tuag casting tshuab thiab hliv rau hauv chav tsev compression. Cov hlau yog hydraulic nias rau hauv pwm los ntawm nias qhov piston, thiab cov nyiaj seem hlau yog thawb tawm los ntawm lwm lub zog.

Cov cua txias chamber tuag casting tshuab

Cov cua txias chamber tuag casting tshuab

Lub kab rov tav txias cua txias tuag lub tshuab casting yog tib yam li lub feem ntsug, tab sis lub zog piston pauv yog kab rov tav. Feem ntau cov niaj hnub tuag casting tshuab yog kab rov tav. Cold-chamber tuag-casting tshuab tuaj yeem tuag-cam khwb cia siab melting point hlau lossis yooj yim oxidized hlau, xws li txhuas, tooj alloys, thiab lwm yam.

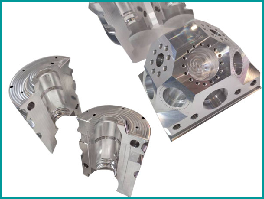

3.Die casting tshuab.

Tuag casting tshuab yog siv rau lub tshuab casting siab. Nws suav nrog ob hom kub nias chamber tuag casting tshuab thiab txias nias chamber tuag casting tshuab. Lub tshuab txias txias nias tuag tuag tshuab tau muab faib ua ob hom: ncaj thiab kab rov tav. Lub tshuab molten tau txhaj rau hauv cov pwm los ntawm lub tshuab tuag-qhov tuag nyob hauv qab qhov kev txiav txim siab ntawm kev ua kom txias thiab sib sau, thiab cov khoom siv hlau ua rau cov hlau tuaj yeem tau tom qab pwm qhib.

Kub chamber tuag casting tshuab

Cov cua txias chamber tuag casting tshuab

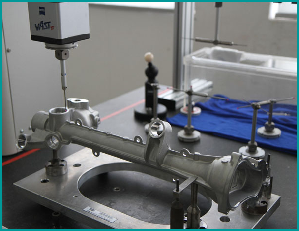

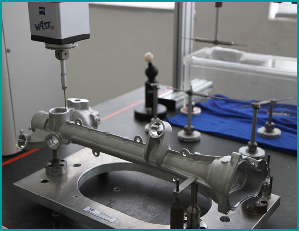

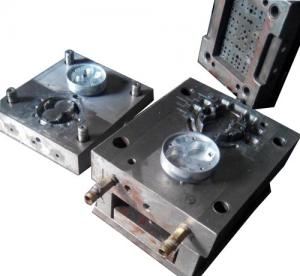

4.Die casting pwm

Hauv pwm ntau yam, cov kev ua haujlwm ntawm kev tuag casting tuag yog qhov hnyav heev. Kev tuag casting yog los ua cov hlau nchuav hlau uas muaj cov pwm kab noj hniav hauv qab lub siab thiab qhov siab nrawm, thiab sib cuag nrog kub hlau dua thaum ua haujlwm. Yog li no, tuag casting pwm yuav tsum muaj lub siab thermal ua haujlwm tsis kam, thermal conductivity thiab hnav tsis kam, corrosion tsis kam, cuam tshuam toughness, liab hardness, zoo demoulding thiab li ntawm. Yog li, txheej txheem kev kho saum npoo ntawm tuag casting tuag yuav tsum tau siv cov thev naus laus zis siab.

Tuag casting pwm

5.Txoj kev ua kom tiav thiab ua tiav rau Tuag Casting Qhov Chaw

Peb muaj ntau cov kev xa tawm thiab cov kev pab ua tiav rau qhov tuag nrum qhov chaw ntawm peb cov neeg xaiv:

Kev pabcuam

CNC machining - ntsug, kab rov tav, tig, 5-axis

Hmoov txheej

Ua kua Txheej

EMI - RFI Shielding

Plating - chrome, tooj liab, zinc, npib tsib xee, tin, kub

Kev Ua Tsis Zoo, Hluav Taws Xob Hluav Taws Xob, Chromating / Tsis-chromating

Kev Kho Huab Cua Sov, Kev Nyuaj Siab, Tumbling

Cov duab

In-house Artwork Txheej Txheem

Kev Ntsuas Kab Yeeb

Kev Luam Ntawv

Ciaj ua kom tawg

Lub Teeb Nruab Nruab Nruab Nrab Sib Daws, suav nrog stud thiab helicoil ntxig, O-nplhaib, gasket

Laser txiav thiab Engraving

Etching

Kev Siv Hluav Taws Xob & Kuaj Hluav Taws Xob