Yas txhaj tshuaj pwm

Cov lus piav qhia luv luv:

Yas txhaj tshuaj pwm yog cov khoom siv rau kev tsim cov khoom yas, uas yog siv rau kev tsim loj. Kev txhaj tshuaj pwm tuaj yeem muab cov qauv tiav thiab qhov loj me rau cov khoom yas tau yooj yim thiab ceev.

Yas txhaj tshuaj yas dab tsi

Yas txhaj tshuaj pwm(txhaj tshuaj pwm) yog ib hom khoom siv los tsim cov khoom yas, thiab tseem yog cov cuab yeej los muab cov khoom yas ua tiav cov qauv thiab qhov loj me. Kev txhaj tshuaj molding yog ib hom kev ua txheej txheem siv nyob rau hauv huab hwm coj ntau yam ntawm qee qhov chaw. Tshwj xeeb, cov yas melted los ntawm tshav kub yog txhaj rau hauv cov pwm kab noj hniav los ntawm kev txhaj tshuaj tshuab hauv qab lub siab, thiab tom qab ntawd txias thiab solidified kom tau txais cov khoom lag luam moulded.

Cov yam ntxwv ntawm kev txhaj tshuaj pwm

1. Kev qhia pwm tuaj yeem tsim cov yas seem nrog cov qauv tsim, qhov loj me thiab kev ua tau zoo sab hauv tib lub sijhawm.

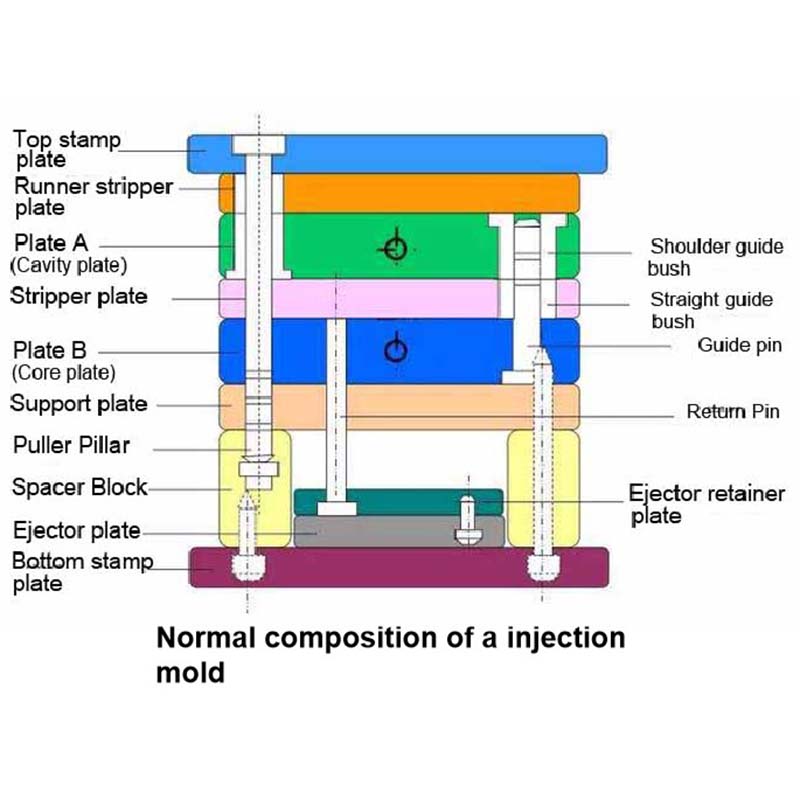

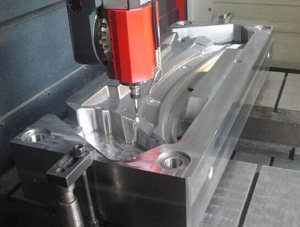

2.Cov qauv txheej txheem ntawm cov pwm yas yuav txawv ntau vim muaj ntau yam thiab ua tiav ntawm cov yas, cov duab thiab cov qauv ntawm cov khoom siv yas thiab hom kev txhaj tshuaj, cov qauv yooj yim zoo ib yam. Cov pwm feem ntau yog tsim los ntawm cov txheej txheem nchuav, kev tswj qhov kub thiab txias, tsim cov ntu thiab cov ntu kev ua haujlwm. Cov txheej txheem sau thiab cov tshuab ua moulding yog cov ntu uas tau nyob hauv cov nplais thiab hloov pauv nrog cov pa roj hmab thiab cov khoom lag luam. Lawv yog cov feem ntau hloov thiab hloov mus hauv cov yas pwm, uas yuav tsum muaj kev ua tiav ntau tshaj thiab raug.

Kev cog lus kev txhaj tshuaj pwm

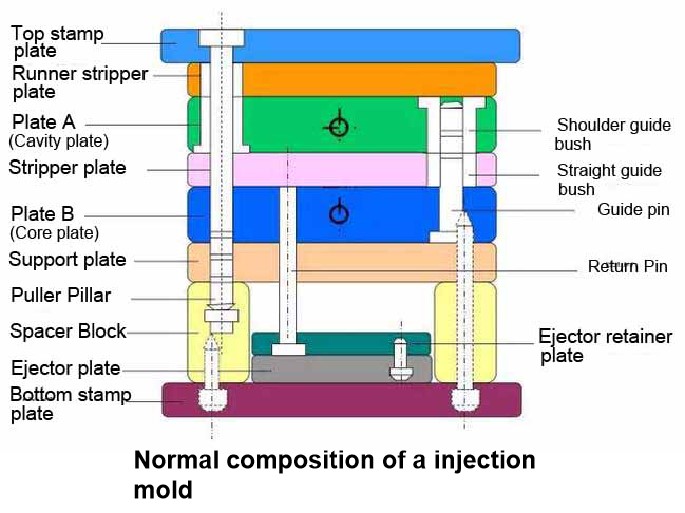

Kev txhaj tshuaj pwm yog tsim los ntawm kev txav cov pwm thiab cov pwm ruaj. Cov pwm txav tau muab tso rau ntawm cov qauv txav mus los ntawm kev txhaj tshuaj moulding tshuab, thiab cov pwm ruaj ruaj yog ntsia rau ntawm cov nplooj ntawv ruaj ruaj ntawm lub tshuab txhaj tshuaj. Thaum lub sijhawm txhaj tshuaj molding, lub txav pwm thiab cov pwm ruaj ruaj raug kaw kom tsim cov txheej txheem ntim thiab cov pwm kab noj hniav. Thaum cov pwm qhib, lub rooj noj rooj noj pwm thiab lub pwm ruaj khov raug muab sib cais kom coj tawm cov khoom yas. Txhawm rau kom txo qhov hnyav ua haujlwm ntawm cov pwm tsim thiab tsim ua lag luam, feem ntau txhaj tshuaj pwm siv cov txheej txheem pwm puag.

Hom pwm raws li kev siv cov yam ntxwv

(1) Cov pwm kub khiav pwm

Nrog kev pab ntawm cov cuab yeej ua kom sov, cov plastics hauv cov txheej txheem yuav tsis ua kom tawv thiab yuav tsis tawg nrog cov khoom, yog li nws tseem hu ua tus tuag tsis tuag. Cov txiaj ntsig zoo: 1) Tsis muaj khib nyiab 2) tuaj yeem txo qhov kev txhaj tshuaj siab, tuaj yeem siv cov kab ntau ntawm cov pwm 3) tuaj yeem ua luv luv rau lub voj voog molding 4) txhim kho cov khoom lag luam zoo tsim rau cov kub khiav moulding yam ntxwv: 5) yas melting kub ntau yog dav. Nws muaj qhov zoo fluidity ntawm qhov kub tsis txias thiab zoo thermal stability thaum kub. 6) Nws yog rhiab rau lub siab thiab tsis ntws tsis muaj lub siab, tab sis nws tuaj yeem ntws thaum thov siab. 7) Zoo cua sov tshwj xeeb, kom txias sai sai hauv qhov tuag. Cov plastics muaj nyob rau qhov kub khiav yog PE, ABS, POM, PC, HIPS, PS. Muaj ob hom kev sib tw kub uas tsis sib xws: 1) cov cua kub khiav hom 2) hom kev sib tw khiav ceev.

(2) Cov pwm nyuaj

Lub thawv steel siv hauv sab hauv tuag xav tau kev kho kub tom qab kev yuav khoom, xws li quenching thiab carburizing, kom tau raws li cov cai ntawm kev siv. Cov pwm txhaj ntawd hu ua nyuaj tuag. Piv txwv, sab hauv tuag adopts H13 hlau, 420 steel thiab S7 steel.

(3) Cov pwm tsis zoo (hauv qab 44HRC)

Cov hlau siv nyob rau hauv cov pwm sab hauv tuaj yeem ua tau raws li qhov yuav tsum tau siv tsis muaj kev kho kub tom qab yuav khoom. Cov kev txhaj tshuaj no yog hu ua mos pwm. Yog tias lub puab tuag sab hauv yog tsim los ntawm P20 steel, trump hlau, 420 steel, NAK80, txhuas thiab beryllium tooj liab.

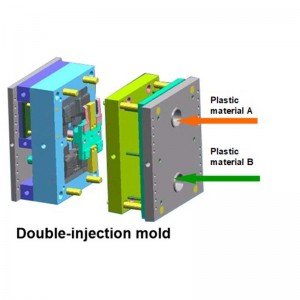

(4) Kev txhaj tshuaj ob npaug pwm

Lub tshuab txhaj ob npaug yog cov pwm uas cov khoom siv ob yas txhaj rau tib lub tshuab txhaj tshuaj moulded thiab txhaj tshuaj pwm ob zaug, tab sis cov khoom lag luam tsuas yog tso tseg ib zaug. Feem ntau, cov txheej txheem molding no tseem hu ua ob txheej kev txhaj tshuaj moulding, uas feem ntau yog ua tiav los ntawm cov txheej txheej pwm thiab yuav tsum tau txhaj ob txoj kev txhaj tshuaj molding tshuab tshwj xeeb

(5) Kev txhaj tshuaj molding nrog hauv-pwm kho kom zoo nkauj & hauv pwm pwm

Yas txhaj tshuaj moulds kev faib tawm los ntawm kev sib kis

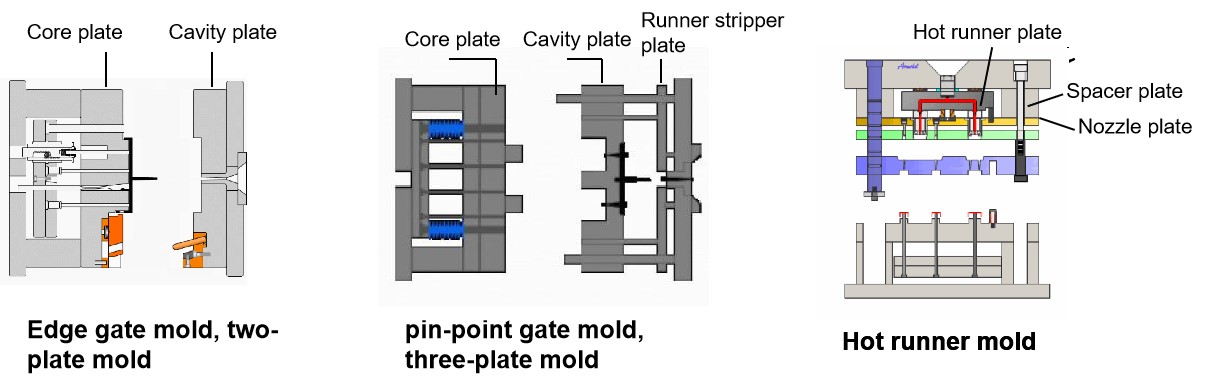

Cov pwm yas ua ke tuaj yeem muab faib ua peb pawg raws li kev sib txawv ntawm qhov sib txawv ntawm cov gating system.

(1) Ntug lub rooj vag pwm (ob-phaj pwm): Khiav thiab lub rooj vag yog demoulded ua ke nrog cov khoom ntawm qhov seem kab. Tus qauv tsim yog qhov yooj yim tshaj plaws, yooj yim rau cov txheej txheem, thiab tus nqi tsawg. Yog li, ntau tus neeg siv cov nozzle loj los ua haujlwm. Cov qauv ntawm cov yas pwm yog muab faib ua ob ntu: dynamic pwm thiab pwm ruaj khov. Qhov txav ntawm lub tshuab txhaj tshuaj yog qhov txav ntawm txav (feem ntau ejection sab), thiab qhov tsis muaj ntawm lub ejection kawg ntawm lub tshuab txhaj yog feem ntau hu ua kev kho qhov pwm. Vim tias qhov chaw tsau ntawm cov loj nozzle tuag feem ntau yog tsim los ntawm ob daim hlau, nws tseem hu ua ob-phaj pwm. Ob-phaj pwm yog cov qauv yooj yim tshaj plaws ntawm cov pwm loj nozzle.

(2) Pin-point rooj vag pwm (peb-phaj pwm): tus neeg khiav thiab lub rooj vag tsis nyob ntawm kab ntu, feem ntau ncaj qha rau ntawm cov khoom, yog li nws yog qhov nyuaj los tsim pab pawg ntawm nozzle parting kab, thiab nyuaj rau txheej txheem Cov. Zoo nozzle system feem ntau xaiv raws li cov khoom xav tau. Qhov chaw ruaj ntawm qhov zoo nozzle molg feem ntau muaj li ntawm peb daim hlau steel, yog li nws tseem hu ua "peb lub phaj pwm" rau hom kev tuag. Peb-phaj pwm yog cov qauv yooj yim tshaj plaws ntawm cov pwm yas tsis zoo.

(3) Cov pwm kub khiav tawm: Cov qauv ntawm hom kev tuag no yeej ib txwm zoo ib yam li cov khoom siv tsis zoo. Qhov loj tshaj qhov sib txawv yog tias tus neeg khiav yog nyob hauv ib lossis ntau qhov kub khiav daim hlau thiab kub nqus dej nrog qhov ntsuas kub tsis tu ncua. Tsis muaj cov khoom lag luam txias txias thiab tus khiav thiab rooj vag ncaj qha rau ntawm cov khoom. Yog li no, tus khiav tsis xav tau demoulding. Qhov system no tseem hu ua tsis muaj lub kaw lus, uas tuaj yeem txuag cov ntaub ntawv nyoos thiab siv tau. Nyob rau hauv cov ntaub ntawv ntawm cov nqi ntau dua raw khoom thiab cov kev cai siab dua rau cov khoom, nws tsis yooj yim rau kev tsim thiab txheej txheem, thiab tus nqi ntawm kev tuag thiab cov pwm muaj siab. Kub khiav tawm lub cev, tseem hu ua qhov khiav kub khiav, feem ntau muaj cov kub khiav lub tes tsho, kub khiav phaj thiab kub tswj lub thawv hluav taws xob. Peb cov kub khiav tawm cov kab ke muaj ob hom: ib-kis kub khiav thiab ntau-taw kev kub khiav. Ib qho taw qhia kub lub rooj vag yog txhawm rau txhaj roj yas ncaj qha rau hauv kab noj hniav los ntawm ib lub rooj zaum kub lub rooj sib txig, uas tsim nyog rau ib kab noj hniav thiab ib lub rooj vag yas pwm; ntau qhov taw qhia lub rooj vag kub yog kom faib cov molten khoom mus rau hauv txhua ceg Thaum Tshav Kub Lub rooj vag lub tes tsho los ntawm lub rooj vag kub thiab tom qab ntawd nkag mus rau hauv kab noj hniav. Nws yog tsim rau tib kab noj hniav, ntau kis pub thiab ntau kab noj hniav

Daim ntawv thov ntawm cov yas txhaj tshuaj moulds

Kev txhaj tshuaj pwm yog cov txheej txheem tseem ceeb rau kev tsim cov khoom lag luam ntau yam. Nrog txoj kev loj hlob sai ntawm kev lag luam yas thiab kev tshaj tawm thiab thov kev siv cov khoom lag luam yas hauv cov chaw lag luam xws li kev tsav dav hlau, huab cua, cov khoom siv hluav taws xob, tshuab, nkoj thiab tsheb, cov kev xav tau ntawm cov khoom ntawm cov pwm kuj tseem siab dua thiab siab dua. Cov qauv tsim pwm ib txwm tsis tau ua tiav raws li qhov kev xav tau ntawm lub sijhawm no. Piv nrog rau kev tsim pwm qub, kev tsim kho computer-aided CAE thev naus laus zis muaj qhov zoo hauv kev txhim kho cov khoom lag luam, kom cov khoom zoo, txo tus nqi thiab txo kev siv dag zog.

1. Cov khoom siv hluav taws xob thiab kev sib txuas lus:

2. Cov khoom siv hauv chaw ua haujlwm;

3. Lub tsheb thauj khoom seem;

4. Khoom siv hauv vaj hauv tsev;

5.Hauv cov khoom siv dag zog;

6. Kho mob thiab kev tiv thaiv ib puag ncig;

7. Muaj cov chaw tsim khoom lag luam;

8.Ntawm kev txawj ntse;

9. Tsheb Thauj Mus Los;

10. Khoom siv hauv tsev, chav ua noj thiab chav dej thiab khoom siv

Mestech yog cov chaw tsim khoom lag luam koom nrog kev txhaj tshuaj pwm tsim thiab txhaj tshuaj qhuav rau ze li 20 xyoo. Peb muaj cov kws tshaj lij pab neeg thiab cov khoom tsim khoom lag luam nplua nuj. Peb tuaj yeem tsim qauv thiab tsim cov yas yas txhaj tshuaj moulding rau peb cov neeg siv khoom. Peb cov pwm txhaj npog hauv tshuab hluav taws xob, hluav taws xob, tsheb, khoom siv kho mob, tsheb thauj mus los thiab khoom siv khoom siv. Yog tias koj xav tau, thov koj xav tiv tauj peb.