Cov khoom siv hlau yog cov hlau thaiv, txuas hlau, ntawv hlau, plhaub hlau, thiab lwm yam. uas yog ua los ntawm cov ntaub ntawv hlau.

Cov ntaub ntawv ntawm qhov chaw hlau: steel thiab nonferrous hlau (lossis non-ferrous hlau). Hlau muaj cov yam ntxwv zoo uas cov khoom siv tsis yog xim hlau xws li cov yas, ntoo, fiber ntau thiab lwm yam, uas tsis tuaj yeem hloov hauv cov khoom lag luam

1. Kev ua haujlwm zoo heev, siv los ua cov chaw hauv conductive, xws li lub cev muaj zog rotor, hluav taws xob hloov, lub qhov (socket).

2. Kev ua kom zoo thermal conductivity, tuaj yeem siv los ua cov cua sov ua kom tsis txhob sov ntawm cov cuab yeej siv tshuab, xws li lub dab cua sov, lub tshuab tshuab, thiab lwm yam.

3. Cov yas zoo, tuaj yeem yog cov yas deformation ntawm cov ntaub ntawv hlau, ua cov tshuab ua haujlwm ntawm ntau hom duab.

4. Zoo weldability.

5. Cov ntaub ntawv hlau muaj cov cuab yeej siab, siab zog thiab tawv.

6. Cov hlau muaj qhov siab tawg thiab tuaj yeem ua qhov tsim nyog rau qhov chaw ua haujlwm kub.

7. Cov hlau qhov chaw tuaj yeem tau txais qhov zoo qhov tseeb thiab qhov chaw zoo, uas feem ntau siv los ua qhov chaw ua tshuab precision.

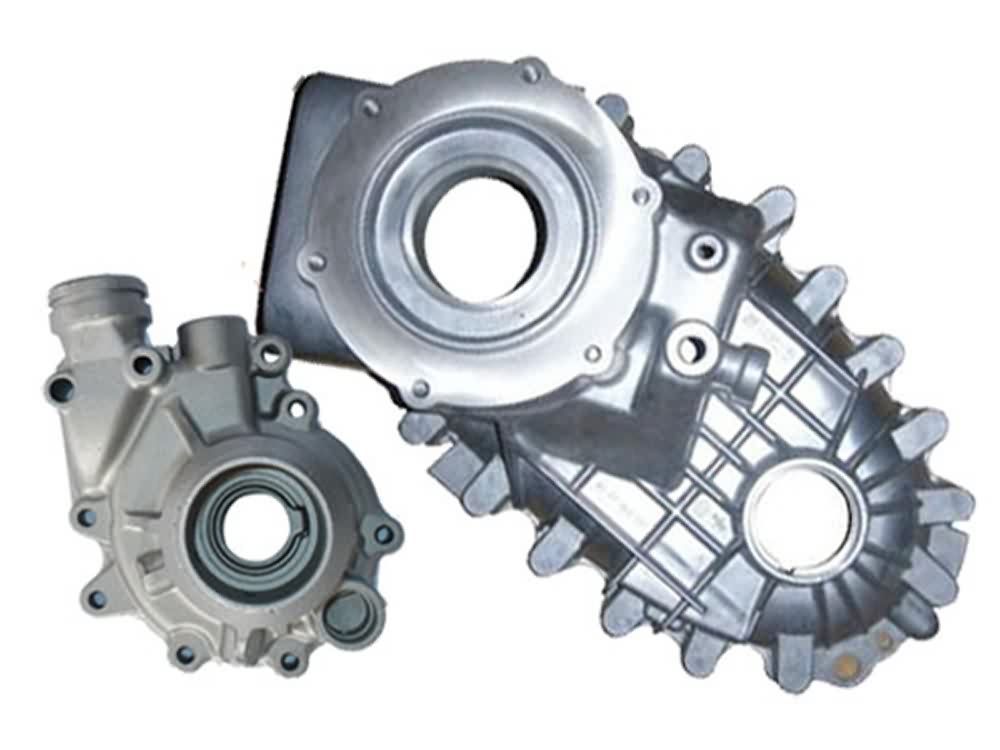

Cov khoom siv hlau yog dav siv hauv cov khoom siv kho tshuab, khoom siv hluav taws xob, kev tsim kho nkoj, chaw ua haujlwm aviation thiab khoom siv hauv tsev. Cov khoom siv hlau ua peb ua rau peb cov neeg siv khoom muaj raws li hauv qab no: Ncej, daim iav, tuag casting, sintering, cov ntawv hlau

Machined qhov chaw

Tuag nrum seem

Stamping qhov chaw

Stainless hlau qhov chaw

Precision hlau qhov chaw

Ncej hlau

Cov cab zog

Aluminium tuag cam khwb cia qhov chaw

Zinc alloy tuag cam khwb cia qhov chaw

Ntawv qhov hlau

Kev siv tshuab ntawm hlau ntu Machining, stamping, precision casting, hmoov metallurgy, hlau txhaj tshuaj, laser machining, EDM, ultrasonic machining, electrochemical machining, particle beam machining thiab ultra-high speed machining. Zoo ib yam li tig, milling, forging, casting, sib tsoo, CNC machining, CNC CNC CNC chaw yog machining cov pa ua.

Cov txheej txheem kho saum npoo

1. Los tiv thaiv xeb thiab tiv thaiv xeb kho: ua kom kub npau thiab xim xiav xiav kuj hu ua phosphating kho, kom lub qhov hlau muaj xeb thiab tiv thaiv xeb.

2. Kev kho cov tawv tawv: cov txheej txheem kev kho mob kom ua tiav qhov nyuaj ntawm cov hlau: qhov carburization saum npoo tau txais los txhawm rau ua kom lub npoo tawv ntawm cov hlau, thiab xim saum npoo yuav tig dub tom qab carburizing; quenching kev kho mob tuaj yeem nce lub hardness;

3. Lub tshuab nqus tsev kho cua sov tuaj yeem txhim kho lub zog tag nrho.

Mestech muab cov qhua tuaj noj mov nrog cov qauv tsim thiab ua cov ntu steel, aluminium alloy, tooj liab, zinc alloy thiab lwm yam hlau. Yog tias koj muaj cov khoom lag luam hlau thiab qhov chaw mus yuav, thov hu rau peb.