Ua pwm

Cov lus piav qhia luv luv:

Ua pwm (Tsim kev tuag) yog txheej txheem kev tsim cov khoom siv raws li cov qauv pwm tsim, siv cov tshuab txiav, txim taws tshuab, kho saum npoo thiab kho cua sov, thiab thaum kawg ua ke txhua feem rau hauv cov pwm raws li cov qauv duab tsim.

Pwm ua & tsim yog qhov kev lag luam tseem ceeb hauv kev tsim kev lag luam niaj hnub no. Nws muab cov txheej txheem tseem ceeb rau cov cuab yeej siv loj, kev ua haujlwm siab thiab kev ua haujlwm siab.

Dab tsi yog pwm?

Pwm (pwm, tuag) yog lub npe hu ua "niam ntawm kev lag luam", uas yog cov txheej txheem tseem ceeb los ua kom tiav qhov siab qhov siab, kev ua haujlwm siab thiab kev lag luam loj hauv kev tsim khoom lag luam niaj hnub no. Hauv kev tsim cov pwm kev lag luam, ntau yam pwm thiab cov cuab yeej siv los txais cov khoom yuav tsum tau los ntawm kev txhaj tshuaj, tshuab moulding, extrusion, pwm casting lossis forging, smelting, stamping thiab lwm txoj kev. Hauv ntej, cov pwm pwm yog qhov cuab yeej siv los ua cov khoom molding. Cov cuab yeej no yog tsim ntawm ntau qhov chaw, thiab cov pwm sib txawv yog tsim ntawm ntau qhov chaw. Nws yog feem ntau ua kom paub tseeb cov txheej txheem ntawm cov duab ntawm cov khoom los ntawm kev hloov lub cev lub cev ntawm cov khoom siv sib sau. Nws yog lub npe hu ua "niam ntawm kev lag luam".

Dab tsi yog pwm tsim?

Yuav luag txhua tus pwm tsim los ntawm cov hlau, thiab 90% ntawm lawv yog ua los ntawm cov hlau.

Raws li qhov kev txiav txim siab ntawm sab nraud quab yuam, lub steel billet ua ib qho khoom siv rau kev tsim khoom nrog cov duab tshwj xeeb thiab qhov loj me. Nws yog dav siv hauv stamping, pwm forging, lub taub hau txias, extrusion, hmoov metallurgy qhov nias, siab casting, thiab ntxiv rau engineering plastics, roj hmab, ceramics thiab lwm yam khoom ntawm compression lossis txhaj tshuaj molding. Cov pwm muaj qhov tshwj xeeb contour lossis sab hauv cov duab ntawm cov duab, thiab qhov khoob tuaj yeem sib cais raws qhov contour puab (blanking) los ntawm kev thov cov contour duab nrog ntug. Cov duab ntawm cov kab noj hniav sab hauv tuaj yeem siv los ua kom tau qhov sib txuam peb ntu ntawm cov billet. Cov pwm feem ntau suav nrog ob ntu: cov pwm txav tau thiab ruaj khov pwm (lossis punch thiab concave pwm), uas tuaj yeem sib cais thiab ua ke. Thaum cov ntu cais, cov xuv tau txhaj rau hauv cov kab noj hniav kom ua rau thaum lawv kaw. Pwm yog qhov cuab yeej npliag nrog cov qauv zoo nkauj thiab muaj cov kabmob sib zog ntawm billet. Nws muaj cov kev cai siab ntawm tus yam ntxwv lub zog, kev coj nruj, sab hardness, saum npoo tawv thiab kev ua haujlwm raug. Kev nce qib ntawm kev tsim pwm yog ib qho ntawm cov cim tseem ceeb ntawm theem ntawm kev siv tshuab.

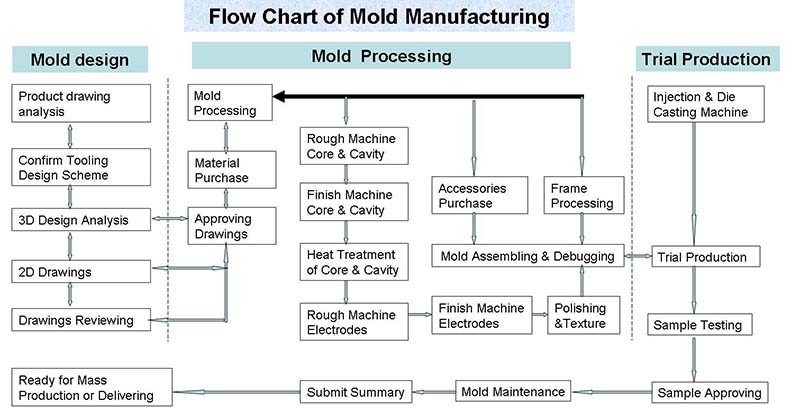

Cov txheej txheem pwm kev lag luam suav nrog: pwm tsim, ua pwm ua, kev kuaj pwm thiab kuaj kev txhaj tshuaj, kev hloov pwm thiab kho pwm, thiab tswj pwm.

Pwm kev tsim cov khoom lag luam feem ntau yog paub los ntawm kev forging, txiav, kev kho cua sov thiab kev sib dhos thiab lwm yam txheej txheem. Txhawm rau kom paub tseeb tias kev tsim khoom zoo ntawm cov pwm thiab txo tus nqi tsim khoom, cov khoom siv yuav tsum muaj malleability zoo, txiav machineability, hardenability thiab grindability, thiab kuj yuav tsum muaj oxidation me, decarbonization rhiab thiab quenching deformation cracking nyiam. Kev txiav tawm yuav siv li ntawm 70% ntawm kev ua haujlwm ntawm kev ua cov pwm. Cov kauj ruam tseem ceeb tshaj plaws yog kom tau txais cov kab noj hniav uas ua tau raws li qhov yuav tsum tau ua ntawm cov duab, qhov ntev thiab qhov zoo ntawm cov av, zoo li tag nrho cov kev ua.

Cov pwm txiav cov txheej txheem

Cov steel seem rau kev ua cov pwm tau dov thiab tsim hauv cov nroj tsuag steel, thiab pwm cog tuaj yeem xaiv ncaj qha rau kev yuav. Kev ua pwm yog ua kom cov xaim steel ua rau hauv cov pwm uas tuaj yeem tsim cov khoom lag luam hauv qhov ntau lawm. Kev tsim cov pwm suav nrog pwm tsim, ua haujlwm ua thiab ua ke ntawm cov pwm pwm thiab pwm puag.

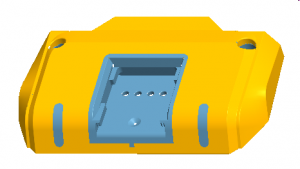

1. Pwm tsim yog ua tiav los ntawm cov kws tshaj lij kws ua haujlwm. Pwm tsim yog tus qauv thiab hauv paus ntawm txhua yam pwm ntau lawm. Raws li cov kev xav tau ntawm cov khoom tsim qauv thiab cov txheej txheem ntawm cov khoom ua kom pom tseeb, cov sijhawm thov thiab cov khoom tsim tawm, nrog rau kev teeb tsa ntawm kev txhaj tshuaj moulding tshuab, tus kws ua haujlwm yuav tsum xaiv cov hlau tsim nyog rau txhua ntu pwm thiab txiav txim siab cov qauv thiab txheej txheem pwm. Qhov meej mom ntawm cov pwm tsim kev txiav txim siab qhov tsim ua teeb meem nyuaj, nqi, kev pabcuam lub neej, kev tsim khoom thiab cov khoom lag luam zoo ntawm cov pwm.

Pwm yog ib hom khoom siv kim kim. Hauv kev tsim qauv, peb cov kws ua choj siv software los tshuaj xyuas thiab simulate qhov ntawm cov khoom faib, ntws kev, qhov taw tes txhaj tshuaj thiab txawm tias tus qauv ntawm feem.

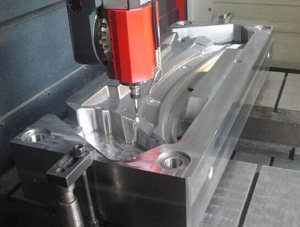

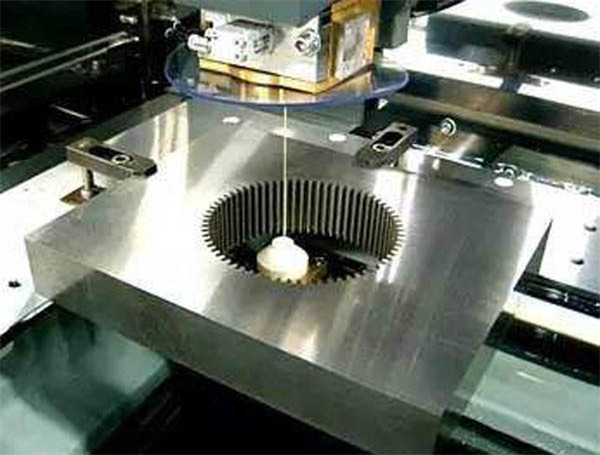

2. Kev siv tshuab pwm. Pwm billet yog ua tiav los ntawm kev siv tshuab ua haujlwm raws li tus qauv tsim qauv thiab cov ntaub ntawv txheej txheem. Feem ntau, cov cuab yeej txiav tshuab thiab cov cuab yeej siv los ua cov pwm muaj xws li CNC, EDM, WEDM, tshuab dhos, grinder, tshuab polishing, etc. Tshaj ntawd thiab cov cuab yeej siv tshuab ua tau zoo tuaj yeem txhim kho lub pwm zoo, luv lub voj voog ntau lawm thiab txo tus nqi. Txawv cov pwm sib txawv siv cov khoom sib txawv ntawm cov tshuab: txhaj tshuaj txhaj tshuaj pwm thiab tuag pwm pwm feem ntau siv CNC, EDM thiab WEDM. Stamping pwm thiab extrusion pwm feem ntau siv CNC thiab WEDM

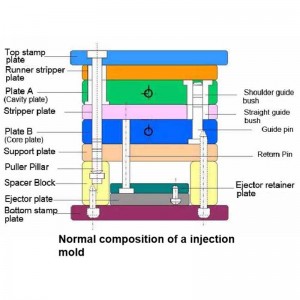

3. Pwm sib dhos. Kev sib dhos ntawm cov pwm nyob ntawm tus kws tshaj lij. Nws suav nrog cov tub ntxhais tuag, swb block, qhia cov ncej, ejection mechanism, txuam ntawm tus ncej tuag thiab lub cev muaj zog, cov sib tw kub khiav, nrog rau feem uas tsis tuaj yeem txiav, thiab qhov kawg tag nrho sib dhos. Qhov siab dua qhov tseeb ntawm kev siv lub tshuab, qhov tsawg dua cov haujlwm ntawm kev sib dhos tuag, lub sijhawm ua haujlwm luv luv thiab cov nqi qis dua. Tom qab ua tiav ntawm kev sib dhos ntawm cov tuag, nws yog ib qho tsim nyog los kuaj, pov thawj, debug thiab txhim kho kev tuag kom txog thaum nws tuaj yeem tsim cov khoom tsim nyog nrog lwm cov khoom.

Cov pwm ua cov txheej txheem

CNC machining

EDM-Hluav Taws Xob Tawm Hauv Machining

WEDM-xaim electrode txiav

Haum thiab sib dhos ua cov pwm

Lub tuam txhab Mestech yog feem ntau koom nrog cov yas ua pwm ua kev lag luam thiab cov khoom txhaj, nrog rau cov pwm tuaj pwm (hlau tuag-tuag tuag, stamping tuag) kev tsim khoom thiab cov khoom siv hlau.