Kev txhaj tshuaj yas yog qhov feem ntau siv los ntawm ib qho ntawm cov yas txhaj tshuaj yas. Kev txhaj tshuaj pwm yas yog siv hauv hluav taws xob, hluav taws xob, hluav taws xob, kho mob, tsheb thauj mus los, tsheb, teeb pom kev zoo, kev tiv thaiv ib puag ncig, kev nyab xeeb, khoom siv hauv tsev, khoom siv ncaws pob thiab lwm yam kev lag luam thiab cov khoom lag luam.

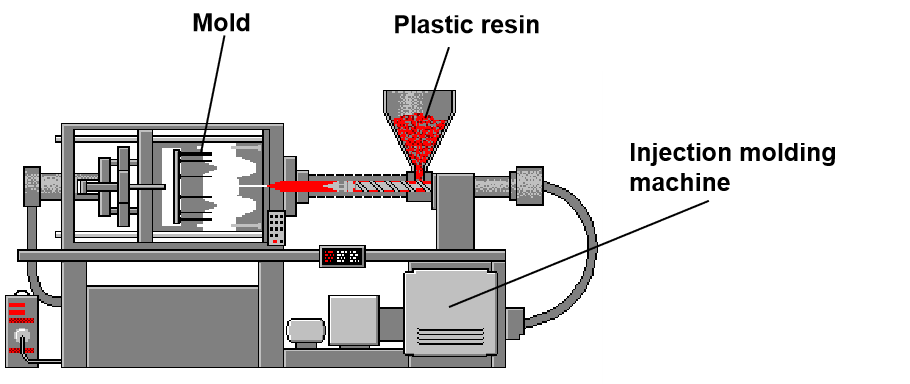

Kev txhaj tshuaj yog dab tsi? Kev txhaj tshuaj yas yog kev tsim cov txheej txheem rau kev tsim cov khoom hauv qee qhov ntsuas kub, los ntawm cov ntsia hlau nplawm cov khoom siv yas kom tiav, kev txhaj tshuaj siab rau hauv cov pwm kab noj, tom qab txias thiab kho kom zoo, kom tau txais cov qauv molding. Hom no haum rau cov batch ntawm cov khoom seem thiab yog ib txoj hauv kev ua tseem ceeb. Nws muaj 6 ntu: pwm kaw, melted yas txhaj tshuaj, tswj kev kub siab, txias, pwm qhib thiab cov khoom tawm. Kev nrawm, siab, txoj haujlwm (mob stroke), sijhawm thiab kub yog 5 yam tseem ceeb ntawm kev txhaj tshuaj molding.

Peb lub ntsiab ntawm kev txhaj tshuaj tiv thaiv chav ua haujlwm

Daim ntawv thov ntawm kev txhaj tshuaj molding khoom

(1) hauv cov khoom siv hluav taws xob: .Cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob (cov vaj tse yas, ntim, thawv, npog) Cov xov tooj ntawm tes, lub mloog pob ntseg, TV, video xov tooj, POS machine, lub qhov rooj.

(2) hauv cov khoom siv hauv tsev: Kas fes tshuab, dej cawv, tub yees, cua txias, kiv cua tshuab ntxhua khaub ncaws thiab lub qhov cub microwave

(3) hauv cov khoom siv hluav taws xob: Cov ntsuas hluav taws xob, lub thawv hluav taws xob, lub thawv hluav taws xob, zaus hloov pauv, rwb thaiv tsev npog thiab hloov

(4) hauv kev kho mob thiab khoom siv kho mob thiab khoom siv hluav taws xob: cov teeb ua haujlwm, sphygmomanometer, koob txhaj tshuaj, tee dej, tshuaj fwj tshuaj, zaws, cov plaub tshem tawm, cov cuab yeej siv qoj

(5) hauv kev siv tsheb: Dashboard lub cev ncej, roj teeb lub rooj, pem hauv ntej lub thawv, tswj lub thawv, lub rooj txhawb nqa ncej, tus me nyuam lub cev, tus fender, bumper, lub puab tsaig npog, suab nrov, qab rooj sab ncej.

(6) Hauv cov khoom lag luam: Cov tshuab ntsuas lub tshuab, cov iav, hloov, cov teeb pom kev zoo.

(7) Cov cuab yeej hluav taws xob thiab cov cuab yeej siv tsheb (cov npog teeb, thaiv tsev) Cov teeb liab teeb liab, kos npe rau, tus ntsuam xyuas cawv.

Peb lub ntsiab ntawm kev txhaj tshuaj tiv thaiv chav ua haujlwm

Pwm, txhaj tshuaj molding tshuab thiab cov khoom siv raw ua lub hauv paus tseem ceeb ntawm kev txhaj tshuaj molding. Kev txhaj tshuaj pwm thiab txhaj tshuaj moulding tshuab yog cov khoom siv ntau lawm, thiab cov khoom siv yas siv los ua cov khoom ntim.

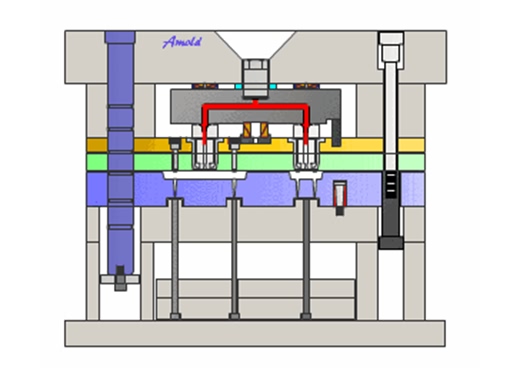

1. txhaj tshuaj moulds

Kev txhaj tshuaj pwm yog ib hom khoom siv los tsim cov khoom yas; nws tseem yog cov cuab yeej los muab cov khoom yas ua tiav cov qauv thiab qhov loj me. Kev txhaj tshuaj molding yog ib hom kev ua haujlwm siv hauv kev tsim khoom siv los ntawm qee qhov chaw ua haujlwm nyuaj. Tshwj xeeb, lub hau yas yog txhaj rau hauv cov pwm kab noj hniav los ntawm kev txhaj tshuaj moulding tshuab hauv qab qhov siab, thiab cov khoom lag luam pwm tau txais tom qab txias thiab kho kom zoo. Kev txhaj tshuaj pwm tuaj yeem muab faib ua ntau hom raws li tus qauv pwm sib txawv, kev tsim khoom tsim qauv, hom ntau lawm thiab teeb tsa thiab siv hom.

Vim tias cov nqi tsim khoom ntawm siab ua lag luam pwm, tab sis lawv cov kev pabcuam ntev lub neej thiab kev ua haujlwm siab ntau, lawv feem ntau tsuas yog siv rau kev tsim ntau lawm. Kev txhaj tshuaj pwm yog siv rau kev tsim ntau hauv tshuab yas. Coob tus nqi ntawm cov khoom lag luam yas siab, zoo sib qhia tus nqi ntawm cov pwm ntau lawm, yog li qhov raug nqi ntawm ib qho khoom lag luam txhaj tshuaj molding yog qhov qis qis tshaj qhov ntawm lwm cov txheej txheem kev lag luam. Muaj peb theem ntawm pwm tsim thiab pwm kev tsim nyog.

(1) Pwm tsim:

Pwm tsim raws li cov khoom tsim, kev siv cov qauv tsim, raws li pwm kev lag luam qib ntawm kev siv tshuab ua thiab kev txhaj tshuaj pwm txheej txheem cov yam ntxwv, tsim ntawm tag nrho cov pwm tshuab, ntu.

(a) Thawj kauj ruam yog los tshuaj xyuas kev tsim cov khoom yas

(b) Qhov thib ob kauj ruam yog xaiv ntawm cov khoom tuag

(c) Qhov thib peb theem yog pwm kev tsim qauv

(d) Qeb plaub yog kev tsim qauv pwm

(2) Pwm ua

Pwm txheej ua ntau yog los ntawm kev siv tshuab los ua kom tiav Kev teeb tsa kev soj ntsuam → kev npaj khoom → kev ua → pwm lub hauv paus ua pwm core pwm cov txheej txheem → pwm txheej txheem → pwm qhov kev soj ntsuam parts pwm tsim kev soj ntsuam → soj ntsuam → sib dhos → ya pwm → sim pwm → pwm

Lub voj voog ua ntawm kev txhaj tshuaj pwm nyob ntawm cov txheej txheem nyuaj thiab txheej txheem qib pwm. Kev tsim tawm dav dav yog 20-60 hnub ua haujlwm. Lub tshuab siv hauv cov pwm ua: CNC, tshuab dhos, dav siv tshuab milling, tshuab nto, EDM, WEDM, ntxiv rau kev sib dhos ntawm cov cuab yeej siv tes, ntsuas lub ntsuas, thiab lwm yam

(3) Hom kev txhaj tshuaj moulds:

Kev txhaj tshuaj pwm tuaj yeem muab faib ua ntau hom raws li cov qauv pwm, tsim cov khoom tsim, hom ntau lawm thiab teeb tsa thiab siv hom.

(a) Ob lub phaj pwm: hauv kev txhaj tshuaj moulding, lub tshuab txav txav thiab lub pwm ruaj khov ntawm cov pwm tau sib cais, thiab tom qab ntawd cov yas seem raug rho tawm, tseem hu ua ob lub phaj pwm. Nws yog ib qho yooj yim heev thiab siv tshuab txhaj tshuaj yas. Nws tuaj yeem tsim raws li cov kab noj hniav txhaj ib leeg lossis ntau kab noj hniav txhaj pwm raws li qhov kev thov. Nws yog cov khoom siv dav siv txhaj tshuaj pwm. Pwm rau ib lossis ntau kab noj hniav txhaj tshuaj molding,

(b) Peb phaj pwm: tseem hu ua ob npaug puab ntu tuaj pwm. Piv nrog rau kev one-thooj sab nrauv txhaj tshuaj pwm, lub dual sib cais txhaj tshuaj pwm ntxiv ib qho txav ntawm qhov chaw txav ntawm cov pwm ruaj ruaj rau cov qhov rooj laj kab pwm. Vim tias nws cov qauv tsis yooj yim thiab kev tsim khoom siab, feem ntau tsis siv rau hauv cov pwm ntawm qhov loj.

(c) Cov pwm kub khiav pwm: kub khiav pwm pwm hais txog cov pwm uas siv cov khoom siv cua sov los ua kom cov yaj hauv cov channel tsis khov txhua lub sijhawm. Vim tias nws ua tau zoo dua li kev tsim cov pwm qub, thiab txuag tau ntau dua li cov khoom siv raw, yog li cov kub khiav pwm hauv lub tebchaws niaj hnub tsim thiab thaj chaw tau siv dav. Qhov kub khiav lub tshuab muaj ib lub tshuab kub ntau dua lub cev dua li ntawm hom pwm, yog li tus nqi ntau.

(d) Ob xim pwm: feem ntau hu ua ob yam khoom siv yas hauv tib lub tshuab txhaj tshuaj moulding tshuab txhaj tshuaj, ob moulding, tab sis cov khoom lag luam pwm ib zaug xwb. Feem ntau, cov txheej txheem molding no tseem hu ua kev txhaj tshuaj ob npaug, uas feem ntau yog ua tiav los ntawm cov txheej pwm, thiab yuav tsum tau siv cov tshuab txhaj tshuaj ob-xim tshwj xeeb.

(4) Cov kab ke tsim kho ntawm kev txhaj tshuaj pwm yog li hauv qab no

Kev txhaj tshuaj pwm feem ntau yog tsim nrog cov txheej txheem hauv qab:

(a) Gating system. Nws yog hais txog cov yas ntws channel hauv pwm los ntawm kev txhaj tshuaj mus rau qhov kab noj hniav. Cov kev sib tw nquag muaj li ntawm sprue, distributor, rooj vag thiab lub qhov txias.

(b) Sab sib tshooj thiab tub ntxhais rub tshuab.

(c) Kev qhia kev tawm tsam. Hauv cov pwm yas, nws feem ntau muaj cov haujlwm ntawm kev ua haujlwm, kev coj ua thiab coj qee lub siab ceev kom paub tseeb tias qhov raug ntawm txav thiab ruaj ruaj pwm kaw. Kev tuag kaw kev coj ua lub ntsej muag yog tsim ntawm cov txheej txheem ncej, phau ntawv qhia lub tes tsho lossis phau ntawv qhia lub qhov (ncaj qha qhib rau ntawm tus qauv) thiab muab tso rau saum npoo.

(d) Ejection / demoulding mechanism. Xws li thawb tawm thiab cov tub ntxhais rub tawm. Nws yog tsuas yog siv los txhaws cov ntu los ntawm cov pwm. Nws yog li ntawm ejector pas nrig lossis cov yeeb nkab jacking lossis thawb phaj, ejector phaj, ejector pas nrig phaj, rov pib qws thiab rub pas nrig.

(e) Kev tswj qhov kub thiab txias. Cua txias thiab cua sov pab kiag.

(f) Tsis kaw neeg.

(g) Cov Pwm ntu xa mus rau cov ntu ua ntu ua cov pwm ua kom zoo. Nws feem ntau suav nrog: punch, poj niam tuag, tub ntxhais, sib sau tus pas nrig, sib sau lub nplhaib thiab ntxig.

(h) Tsau tsau thiab ntsia ntu. Cov.

(5) Cov khoom siv rau pwm

Cov yas pwm yas suav nrog thermoplastic pwm thiab thermosetting yas pwm. Cov hlau rau yas pwm yuav tsum muaj qee yam khoom xws li lub zog, tawv tawv, hnav tsis kam, thermal stability thiab corrosion tsis kam. Tsis tas li ntawd, nws tseem yuav tsum muaj cov txheej txheem zoo, xws li kev kho cua sov me me, kev ua haujlwm zoo dua, zoo dua corrosion, zoo dua kev sib tsoo thiab polishing, zoo dua kev kho vuam kev ua haujlwm, siab roughness, zoo thermal conductivity thiab ruaj khov loj thiab cov duab ntawm kev ua haujlwm tej yam kev mob.

Dab tsi ntawm kev txhaj tshuaj yog siv rau hauv kev txhaj tshuaj pwm muaj qhov cuam tshuam zoo rau xaiv pwm pwm. Yog tias tus neeg sawv cev ntxiv lossis lwm tus neeg sawv cev hloov kho tau ntxiv, xws li iav fiber, qhov kev puas tsuaj rau lub pwm yog qhov loj heev, yog li cov khoom siv xaiv yuav tsum raug txiav txim siab tau zoo. Cov ntaub ntawv muaj zog acid yas yog PVC, POM, PBT; cov ntaub ntawv ua kom tsis muaj zog acid yog PC, PP, PMMA, PA. Feem ntau, S136, 1.231, 6420 thiab lwm cov hlau pwm tau xaiv rau cov hlau uas tsis muaj zog, thaum S136, 1.2316420, SKD61, NAK80, pak90718, thiab lwm yam tuaj yeem xaiv rau cov tawv nqaij tsis muaj zog. Cov tsos uas xav tau ntawm cov khoom kuj tseem muaj qhov cuam tshuam zoo xaiv cov khoom siv pwm. Rau cov ntu pob tshab thiab cov khoom lag luam nrog daim iav nto polishing, cov ntaub ntawv muaj S136, 1.2316718, NAK80 thiab pak90420. Cov pwm nrog lub siab pob tshab yuav tsum xaiv S136, ua raws 420. Yog tias tsuas yog ua tau raws cov khoom xav tau yam tsis muaj kev txiav txim siab txog tus nqi thiab tus nqi, tej zaum yuav tsis yog tus tsim qauv zoo, pwm tsim nqi kuj yog qhov tseem ceeb tshaj

2.1njection molding cov khoom siv

(1). Txhaj tshuaj molding tshuab:

nws yog cov khoom siv moulding tseem ceeb rau kev ua cov thermoplastic lossis thermosetting yas ua ntau yam duab ntawm cov khoom lag luam yas los ntawm yas moulding Kab rov tav txhaj moulding tshuab, ntsug txhaj tshuaj molding tshuab, ob xim txhaj tshuaj molding tshuab, tag nrho fais txhaj moulding tshuab Txawm li cas los xij, tsis muaj teeb meem zoo li cas ntawm txhaj tshuaj molding tshuab, nws cov haujlwm yooj yim yog ob:

(a) Sov cov yas kom yaj.

(b) Kev ntsuas kub siab tau thov rau cov roj hmab yas rau eject thiab sau cov kab noj hniav. Cov kev txwv tseem ceeb ntawm kev txhaj tshuaj moulding tshuab yog: clamping quab yuam, siab txhaj ntau, qhov siab tshaj plaws thiab qhov tsawg kawg nkaus pwm tuab, txav stroke, rub tus pas nrig yov, ejection mob stroke thiab ejection siab. Rau cov seem nrog ntau qhov sib txawv, cov qauv thiab cov khoom siv, nrog rau cov pwm ntawm qhov sib txawv thiab ntau hom, qauv sib txawv thiab ntsuas ntawm kev txhaj tshuaj molding tshuab yuav tsum tau xaiv. Tag nrho cov tshuab fais fab txhaj moulding muaj qhov zoo ntawm kev txhaj tshuaj siab, kev tswj zoo thiab ua kom tiav ntau lawm. Nws yog siv rau kev txhaj tshuaj molding ntawm qee qhov ua kom raug.

(2) Cov khoom siv pabcuam:

(a) Kev tswj hwm ntawm kev txhaj tshuaj moulding tshuab yog kev siv tshuab tsis zoo no feem ntau tuaj yeem qog qee qhov haujlwm ntawm tib neeg sab saud, thiab tuaj yeem tswj nws kom thauj khoom lossis kev siv cuab yeej raws li kev xav tau ua ntej. Tus ntsuas tswj tau tuaj yeem ua kom tau qhov xwm yeem ntawm lub voj voog ua haujlwm, txhim kho kom zoo thiab ua kom zoo dua qub. Nrog rau txoj kev loj hlob sai ntawm kev siv yas ua kev lag luam hauv Suav teb, cov qib ntawm kev siv tshuab txhaj tshuaj molding yog nce siab dua thiab siab dua. Niaj hnub no txhaj tshuaj molding tshuab yog feem ntau nruab nrog cov thev naus laus zis los txhim kho kev ua haujlwm ntau lawm.

(b) Roj rhaub dej / cov tshuab dej ua kua dej: ua kom sov los yog cua txias los ntawm cov kua ntws los ntawm cov pwm, nce pwm nce siab, txhim kho kom zoo dua qub, lossis txo cov pwm kub kom zoo dua rau cov khoom lag luam.

(c) Kev siv tshuab dehumidification: tshem tawm ya raws ntawm cov khoom yas los ntawm cua kub thiab tshuab.

Kev txhaj tshuaj pwm rhiav

Txhaj tshuaj molding ntau lawm kab

Yas ntu tha xim kab

3.Cov ntaub ntawv zoo nkauj

Cov khoom siv yas siv hauv kev txhaj tshuaj molding: Hauv qab no yog cov tshuaj siv feem ntau siv hauv kev txhaj tshuaj: Acrylonitrile Butadiene Styrene, Acrylonitrile Butadiene Styrene (ABS), yog opaque thermoplastic thiab amorphous polymer. ... Polyethylene. ... Polycarbonate. ... Polyamide (Nylon) ... Ua Rau Muaj Siab Polystyrene. ... Polypropylene

| Cov khoom siv | Yog ceev | Pwm Ntshws |

Ntseg | Thov |

| Qauv / cm3 | % | |||

| ABS(Acrylonitrite Butadiene Styrene) | 1,04 ~ 1.08 | 0.60 | Ruaj khov loj, zoo txhua yam khoom siv,yooj yim electroplating, txhaj tshuaj molding yooj yim | yas vaj tsev rau cov khoom lag luam hluav taws xob |

| PC (Polycarbonate) | 1.18 ~ 1.20 | 0.50 | Kev cuam tshuam zoo lub zog, ruaj khov loj thiab rwb thaiv tsev zoo.Cov tshuaj tiv thaiv corrosion tsis zoo thiab hnav tsis kam | yas tsev, tiv thaiv npog, cov khoom xa me me rau cov khoom siv hluav taws xob, cov khoom hluav taws xob |

| PMMA(Polymethyl methacrylate) | 1.17 ~ 1.20 | 0.60 | Nws muaj cov transmittance zoo ntawm 92% thiab cov txiaj ntsig zoo suav lub zog.Nto cuam tshuam lub zog yog tsawg, yooj yim rau kev tawg | Looj tsom iav thiab tso saib hu cov cim ntsuas ntawm twj paj nruag |

| PP(Polypropylene) | 0.89 ~ 0.93 | 2.00 | Nws muaj lub siab ntsws siab heev, noo noo tsis kam,siab kub ua hauj thiab tsis yooj yim dua kua muag.Tsawg coj kuj, yooj yim rau kev laus, kev ua haujlwm tsis zoo yog kub | Cov thawv ntim khoom noj, ntim khoom siv, microwave qhov cub thawv, ntim tshuaj kho mob |

| (chloride) | 1.38-1.41 | 1.50 | Tawv, hnav-resistant, zoo rwb thaiv tsev, sib sau ua ntau nyuaj, ua tsis tau zoo yog kub-ua haujlwm | Ua rau cov kav dej thiab xa tawm |

| Nylon | 1.12 ~ 1.15 | 0.7-1.0 | Muaj zog, hnav-resistant, dej-resistant, qaug zog tiv taus, zoo rwb thaiv tsev. High shrinkage, qhia | Qhov hauv tshuab, tshooj tshuaj, kis ntu |

| POM (Polyacetel) | 1.42 | 2.10 | Txhua yam khoom zoo heev, lub zog siab thiab hardness, hnav tsis kam thiab feem cuam. Tsis zoo thermal stability | Qhov hauv tshuab, tshooj tshuaj, cov khoom sib kis, qhov sib txhuam thiab cov khoom xa tawm ua haujlwm ntawm chav tsev kub |

| TPU(Cov Thermoplastic Polyurethane) | 1,05 ~ 1.25 | 1.20 | Elastomer, hnav-resistant, roj resistant, siab thiab qis kub elasticity, tsis muaj tshuaj lom | Siv dav hauv kev kho mob, khoom noj khoom haus, cov khoom siv hluav taws xob thiab qhov kub tsawg ib puag ncig |

Kev txhaj tshuaj molding cov txheej txheem yog txheej txheem uas cov yaj ua tiav cov khoom siv kom nruj, txhaj tshuaj, txias thiab sib cais los tsim cov qauv ntawm cov khoom ua tiav ib nrab. Txoj kev txhaj tshuaj dav dav ntawm cov ntu yas feem ntau suav nrog 7 theem. : Parameter teeb -> pwm kaw-> txhaws-> (roj pab, dej pab) siab tswj -> txias -> qhib pwm -> mauv.

Kev nrawm, siab, txoj haujlwm (mob stroke), lub sijhawm thiab ntsuas kub yog tsib qhov tseem ceeb ntawm kev txhaj tshuaj molding txheej txheem. Hauv kev txhaj tshuaj molding ntau lawm, nws yog ib qho tseem ceeb los debug cov kev txhawm rau txhawm rau txhim kho thiab tau txais qhov loj me thiab cov tsos.

Xya kev txhaj tshuaj molding tshuab thev naus laus zis

1. Ob chav txhaj tshuaj molding

2. Tshaj dhau-txhaj tshuaj molding

3. Kub khiav txhaj tshuaj molding

3. IMD: hauv-mould kho kom zoo nkauj txhaj tshuaj

4. Txhaj tshuaj ntawm qhov loj

5. Txhaj moulding ntawm highlight qhov

6. Txhaj moulding ntawm qhov chaw tsheb

7. Cov ntsa ntu ntawm kev txhaj tshuaj

Ncej lag luam

Peb tuaj yeem muab koj cov yas txhaj tshuaj moulded qhov chaw hauv ntau cov qauv kev txhaj tshuaj mouldable polymer thiab hauv qhov ntim ntawm 0.1gram-10kgs uas koj xav tau. Tsis tas li ntawd, peb tuaj yeem dhau-molding xov cov lus ntxig, hlau fret txuas lossis lwm cov yas txhaj tshuaj ua ntu rau muab koj cov khoom zoo. Kev sib sau ua ke tseem tuaj yeem tsim los ua ib feem ntawm peb cov kev txhaj tshuaj yas txhaj tshuaj thiab ntim rau koj cov kev xav tau. Tib yam siv rau ntau cov kev ua tiav, suav nrog:

* Chrome plating yas

* Xim

* Kev thaij duab digital

* Daim ntawv luam ntawv

* RF kev tiv thaiv

* Ntim thiab stillage's

* Kev txhaj tshuaj moulding kev tswj zoo Peb kuj muab cov cuab yeej ceev ceev, tiv thaiv thiab kev pab cuam xa duab.

Kev txhaj tshuaj pwm thiab daws teeb meem

Tom qab moulding, muaj qee qhov sib txawv ntawm cov yas thiab cov qauv tau ua qauv zoo (qauv kuaj), uas tsis tuaj yeem ua tau raws li cov kev xav ntawm cov txheej txheem tom ntej. Qhov no yog qhov tsis txaus ntseeg ntawm cov khoom seem yas, uas feem ntau hu ua teeb meem zoo. Peb yuav tsum kawm cov laj thawj ntawm cov kev tiv thaiv no thiab txo lawv kom tsawg. Feem ntau hais lus, cov kev tsis ncaj ncees yog tshwm sim los ntawm cov hauv qab no: pwm, cov ntaub ntawv raw, cov txheej txheem cov txheej txheem, khoom siv Ib puag ncig thiab cov neeg ua haujlwm.

1.Cov cov teeb meem tshwm sim:

(1). Xim qhov sib txawv: yog tias cov xim ntawm txhaj tshuaj molding qhov sib txawv ntawm cov qauv xim ib leeg los ntawm qhov muag liab qab, nws yuav raug txiav txim raws li xim sib txawv raws li cov txheej txheem teeb pom kev zoo.

(2). Cov dej tsis txaus sau (tsis muaj kua nplaum): qhov txhaj tshuaj txhaj tshuaj tsis puv, thiab muaj npuas, voids, shrinkage qhov, thiab lwm yam, uas tsis ua rau cov qauv txheem, uas hu ua kua nplaum tsis txaus.

(3). Warping deformation: cov duab hauv cov yas yuav tig thiab ntswj tom qab tawg los yog lub sijhawm tom qab. Yog tias lub ntsej muag ncaj tig mus rau sab hauv lossis sab nraud, lossis lub tiaj tiaj tiaj muaj nce thiab nqis, yog tias cov khoom ko taw tsis sib npaug, nws hu ua deformation, uas tuaj yeem muab faib ua qhov chaw deformation thiab tag nrho deformation.

(4). Weld kab cim (cov kab): cov kab ib kab ntawm qhov chaw ntawm cov yas, tsim los ntawm kev sib txuas ntawm cov yas hauv cov pwm, tab sis cov hmoov yaj tsis tso tag nrho ua ke ntawm lawv qhov kev sib tshuam, yog li lawv tsis tuaj yeem fused rau ib qho. Lawv feem ntau yog cov kab ncaj, txhim kho los ntawm qhov tob mus rau qhov ntiav. Qhov tshwm sim no muaj qee qhov cuam tshuam rau cov tsos thiab cov khoom siv kho tshuab.

(5). Ripple: qhov saum npoo ntawm kev txhaj tshuaj pwm muaj qhov muab kauv lossis huab zoo li waviness, lossis sab hauv ntawm cov khoom pob tshab muaj cov qauv laim ntoom, uas yog hu ua ripple.

(6). Tshaj ntug (flash, Cape).

(7). Qhov loj me tsis sib xws: shrinkage thiab warpage ntawm txhaj tshuaj moulded qhov chaw hauv cov txheej txheem molding

2. Kev tswj zoo thiab txhim kho: Nws suav nrog kev siv cuab yeej technology thiab kev tswj hwm

(1). Cov txheej txheem theem: kev xaiv cov ntaub ntawv tsim, cov qauv tsim qauv, kev xaiv cov khoom tsim nyog ntawm pwm, kev ua kom zoo ntawm cov qauv pwm tsim los pab txhawm rau txhawm, txhaws thiab qhov chaw tshem tawm, tsim nyog ntawm kev faib cov npoo, ntws channel thiab roj hmab inlet; kev siv cov khoom siv txhaj tshuaj siab lossis cov txheej txheem.

(2). Qib kev tswj: kev tswj kom zoo ntawm cov khoom nkag, tsim cov kev cai thiab cov qauv zoo, kev qhia ua haujlwm, tsim cov txheej txheem tsim nyog cov txheej txheem, sau cov ntaub ntawv thiab tshuaj xyuas, thiab tsim kom muaj lub suab zoo.

Lub tuam txhab Mestech tsim ntau pua pwm thiab ntau lab ntawm cov khoom yas rau cov neeg muas zaub hauv zos thiab thoob ntiaj teb hauv ib lub xyoo. Yog tias koj xav paub ntau ntxiv lossis nug txog cov lus hais txog kev txhaj tshuaj yas moulding, thov hu rau peb hnub no.