Hlau ntu tsim

Cov lus piav qhia luv luv:

Hlau qhov chaw tsim muaj cov ntsiab lus txhais ntawm cov txheej txheem, qhov ntev, qhov tseeb ntawm cov khoom thiab cov khoom siv kho tshuab, thiab thaum kawg tawm cov duab kos rau qhov kawg qhov kev tsim khoom.

Cov khoom siv hlau yog siv dav hauv ntau yam lag luam. Hlau ntu tsim yog qhov ntawm cov hlau qhov hauv lub neej. Mestech muab txhua yam meej ntawm cov hlau ua cov txheej txheem, kev ua kom yooj yim thiab kev ua kom yooj yim rau cov khoom siv sib txuas lus, cua tshuab, khoom siv kho mob thiab khoom siv hluav taws xob.

Cov khoom siv lub cev thiab tshuaj, qhov loj me, cov qauv, kev siv ib puag ncig thiab kev siv ntawm ntau yam hlau yog txhua tus suav thiab ntau yam, thiab lawv cov txheej txheem thev naus laus zis tseem muaj ntau.

Txhawm rau ua haujlwm zoo hauv kev tsim cov hlau, muaj peb yam tseem ceeb uas peb yuav tsum ua kom pom tseeb.

1.Cov siv ib puag ncig ntawm cov feem thiab qhov xav tau ntawm qhov zoo

(1). Qhov loj me me yuav tsum muaj

(2). Hardness yuav tsum

(3). Qhov tseeb ntawm qhov tseeb

(4). Kev tiv thaiv corrosion yuav tsum

(5). Lub zog yuav tsum tau ua

(6). Cov ntaub ntawv yuav tsum ua kom nruj

(7). Hluav taws xob thiab thermal conductivity raws

(8). Yuav tsum hnyav

(9). Txoj cai tiv thaiv kev ua haujlwm

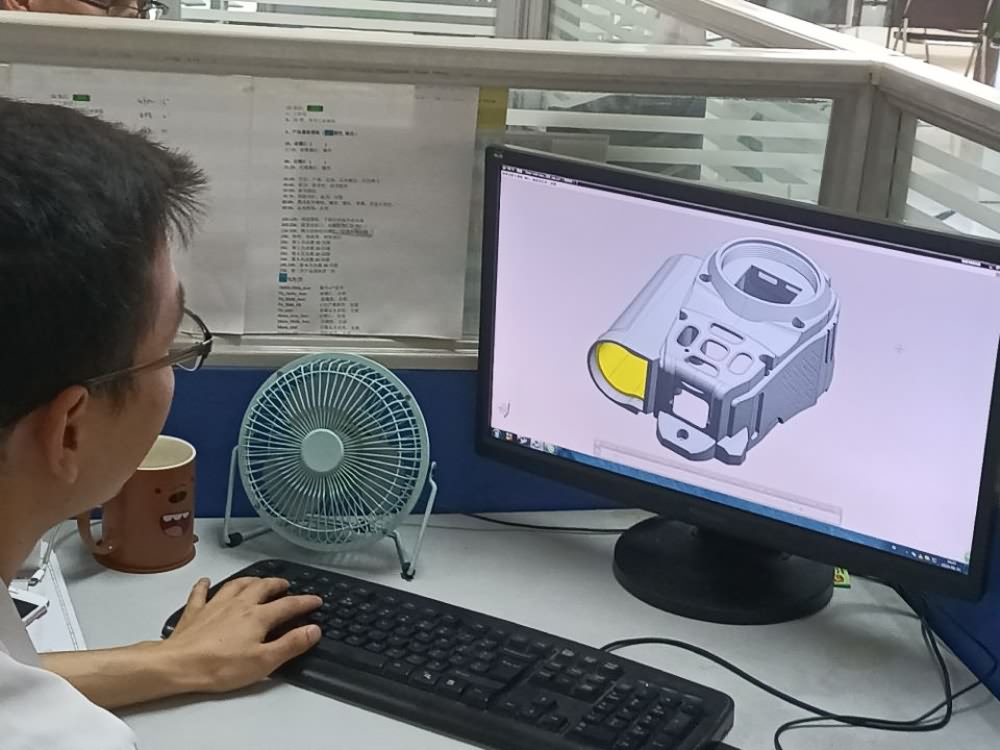

Kws tsim qauv qauv tsim

2. Xaiv cov khoom siv yog

Cov hauv paus ntsiab lus ntawm kev xaiv cov khoom siv rau kev tsim cov khoom hlau yog li hauv qab no:

(1). ua tau raws li kev siv cov kev ua tau zoo: cov khoom siv yuav tsum ua tau raws li cov qauv tsim ntawm lub zog, tawv, tawv, coj thiab lwm yam ntsuas.

(2) Kev ua haujlwm zoo: yooj yim rau cov txheej txheem thiab cov khoom lag luam ruaj khov, kom ntseeg tau tias tus nqi siab dhau, thiab ua kom tau raws li cov qauv tsim ntawm qhov ntsuas qhov tseeb thiab qhov ua tau zoo.

(3) Kev khwv nyiaj txiag: nws tuaj yeem paub cov khoom lag luam loj nrog tus nqi qis.

Tiaj tus kabmob thiab cov kabmob ua haujlwm

Iav tsim

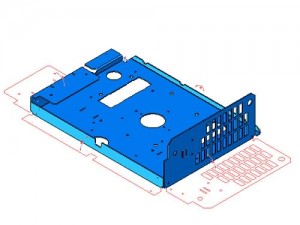

Stamping tshooj

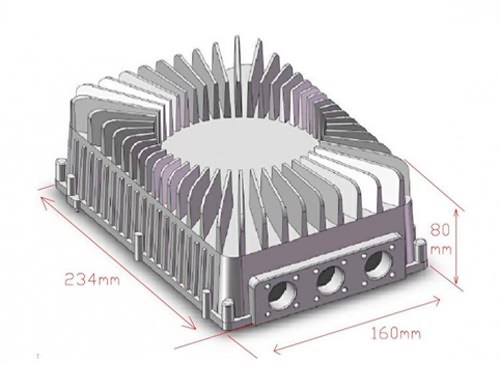

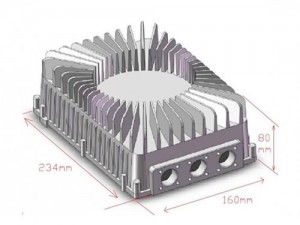

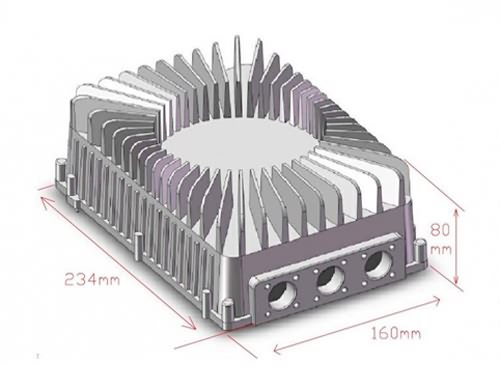

Aluminium tsev

Xav txog kev siv tshuab ua haujlwm ntawm cov khoom, uas yog, cov qauv tsim yuav tsum xav txog kev siv tshuab ua haujlwm txhawm rau kom paub tseeb cov kev ua tiav thiab qhov tseeb, yuav ua li cas txo kev ua haujlwm nyuaj, nqi thiab txhim kho kev tsim khoom.

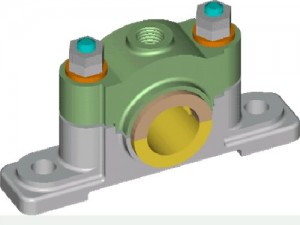

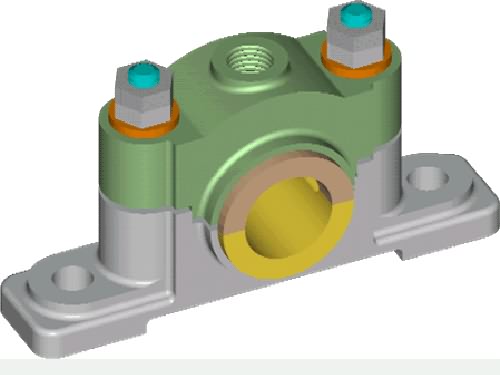

(1) Machining: rau qhov chaw nrog cov khoom siv kho tshuab nruj (lub zog, tawv) thiab qhov ntev thiab qhov tseeb thiab qhov chaw ruaj khov, xws li lub zog, crankshafts, bearings thiab lwm qhov chaw xa mus rau cov cuab yeej siv tshuab lossis kev tsim kho tshuab, hlau lossis tooj liab yog feem ntau xaiv. Lub tshuab machining yog kev txiav tshuab.

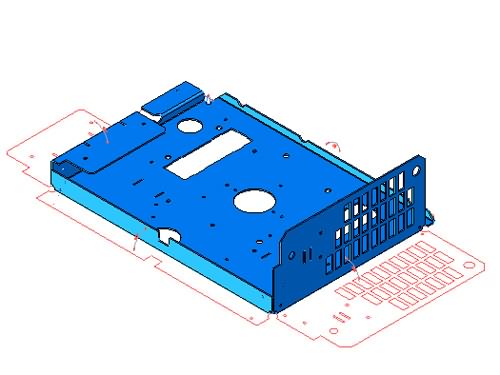

(2). stamping: rau cov phaj hauv daim nyias nyias, xws li ntim, plhaub, lub tog teeb lossis daim ntawv ntu, cov ntawv hlau lossis stamping yog feem ntau siv. Qhov tseeb ntawm cov txheej txheem thev naus laus zis no tau qis dua li ntawm kev txiav, yog li qee qhov ntu nrog qhov yuav tsum tau ua yog xav tau machined.

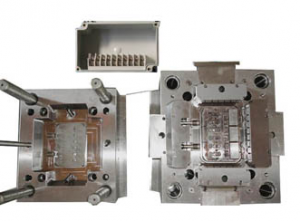

(3) Die casting: rau qee qhov chaw nrog cov qauv duab, feem ntau tsis yog hlau qhov chaw, xws li lub plhaub cav, lub tshuab hluav taws xob thiab lub teeb lub teeb ua ntawm aluminium alloy, zinc alloy, magnesium alloy thiab tooj liab alloy, tuag casting molding tuaj yeem txuag tau ntau qhov txiav tus nqi thiab tau txais tus nqi ntau lawm. Haum rau huab hwm coj ntau lawm.

(4) Lwm cov txheej txheem thev naus laus zis: hlau extrusion yog qhov tsim nyog rau huab hwm coj ntau yam ntawm cov hlau txuas nrog ntu ntu ntu, thiab hmoov sintering yog siv rau kev ua lag luam loj ntawm stainless hlau qhov chaw.

Mestech muab cov qhua tuaj noj mov nrog OEM tsim thiab ua cov khoom ntawm cov hlau. Yog tias koj muaj kev xav tau lossis xav paub ntxiv, thov hu rau peb.