Ob chav txhaj tshuaj molding

Cov lus piav qhia luv luv:

Ob chav txhaj tshuaj molding yog txheej txheem yas moulding uas ob txheej pwm txhaj tshuaj ib txhij txhaj rau tib lub tshuab txhaj tshuaj los ua ib feem ntawm ob cov khoom siv sib txawv yas.

Ob chav txhaj tshuaj molding (tseem hu ua ob chav txhaj tshuaj molding, ob-xim txhaj).

Ob chav txhaj tshuaj molding yog txheej txheem yas kev txhaj tshuaj uas ob txheej pwm txhaj ib txhij txhaj rau tib lub tshuab txhaj tshuaj los ua ib feem ntawm ob cov khoom siv sib txawv yas. Qee zaum ob cov khoom siv ntawm cov xim sib txawv, qee zaum ob cov ntaub ntawv muaj qhov sib txawv hardness thiab softness, yog li tau txais cov khoom xav tau uas muaj thiab lub ntsej muag zoo ntawm cov khoom.

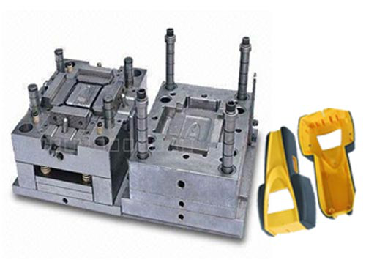

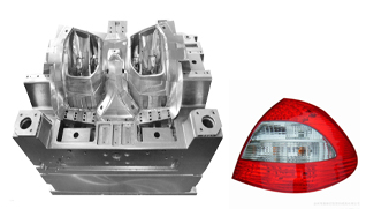

Daim ntawv thov ntawm ob-txhaj yas yas pwm thiab qhov chaw

Cov yas ntim tsim tau txawm hais tias kev txhaj tshuaj ob zaug tau siv dav hauv cov khoom siv hluav taws xob, khoom siv hluav taws xob, khoom siv kho mob, khoom siv hauv tsev, khoom ua si thiab yuav luag txhua lwm cov yas ntim. Kev tsim thiab kev txhaj tshuaj ntawm cov pwm ob-xim pwm, nrog rau kev tshawb nrhiav thiab kev loj hlob ntawm cov tshuab txhaj tshuaj xim ob xim thiab cov ntaub ntawv raw rau kev txhaj tshuaj molding tshuab ob leeg kuj tau tsim sai heev.

Qhia cov kis ntawm ob leeg txhaj tshuaj

Ob qhov sib txawv ntawm cov plastics raug siv, thiab cov khoom siv yas uas tuaj yeem pom meej meej ntawm ob hom ntawm plastics yog hu ua kev txhaj ob npaug.

Dab tsi yog qhov zoo ntawm ob chav txhaj tshuaj molding?

Piv nrog tshuaj txhaj tshuaj moulding, dual-txheej txheej kev txhaj tshuaj molding txheej txheem muaj cov yam ntxwv zoo li nram no:

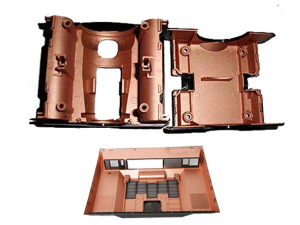

1. Lub puab txheej thiab txheej sab nraud ntawm cov khoom coj los siv cov khoom sib txawv nrog cov yam ntxwv sib txawv, xws li cov uas muaj lub zog zoo hauv cov txheej txheej sab hauv thiab cov uas muaj xim lossis noob nplej rau sab nraud, thiaj li ua kom tau txais kev ua tau zoo thiab pom cov nyhuv.

2. Cov khoom siv ua kom sib xyaw ua kom sib haum: lub cev lub cev ntawm ib feem siv cov khoom siv nyuaj, qhov sib dhos txuam qhov chaw uas siv cov khoom siv ua kua muag (TPU, TPE) tuaj yeem ua si zoo heev ua kom zoo rau cov khoom lag luam, xws li dej tsis haum, hmoov av-pov thawj.

3. Raws li cov kev siv sib txawv, xws li txheej txheej saum npoo ntawm cov khoom hnyav siv cov yas mos yas, lub cev lossis qhov tseem ceeb ntawm cov feem siv tawv yas yas lossis cov yas ua npuas tuaj yeem txo qhov hnyav.

4. Cov khoom siv hluav taws xob tsis muaj zog tuaj yeem siv los txo nqi.

5. Cov khoom siv tseem ceeb ntawm cov khoom tuaj yeem siv cov khoom kim thiab tshwj xeeb saum npoo av, xws li cuam tshuam los tiv thaiv hluav taws xob, kev cuam tshuam loj thiab lwm cov khoom siv los ua kom cov khoom lag luam zoo.

5. Qhov saum npoo lossis qhov tseem ceeb ntawm cov khoom seem tuaj yeem ua cov khoom siv kim nrog cov khoom tshwj xeeb, xws li cov khoom siv hluav taws xob los tiv thaiv, kev cuam tshuam zoo thiab lwm cov khoom siv los ua kom muaj khoom zoo.

6. Kev sib xyaw kom zoo ntawm cortical thiab cov ntaub ntawv tseem ceeb tuaj yeem txo cov kev ntxhov siab, ua kom lub zog ntawm cov neeg kho tshuab lossis cov khoom zoo nkauj ntawm qhov chaw.

7. Piv nrog overmolding, nws muaj qhov zoo nyob rau hauv zoo, nqi thiab khoom tsim khoom.

Qhov luv ntawm ob chav txhaj tshuaj molding

1. Nws yog qhov yuav tsum tau nqis peev rau kev yuav khoom ntawm ob chav txhaj tshuaj molding tshuab.

2. Qhov sib xyaw ua ke ntawm ob-txhaj moulds yuav tsum tau muaj kev ncaj ncees: cov pwm yas tom qab muaj qhov sib luag. Thaum cov khoom muaj cov qauv hloov, ob lub pwm muaj kev hloov pauv tib yam kom ntseeg tau zoo ib yam. Qhov no ntxiv kev ua haujlwm rau kev saib xyuas lub tuag.

3. Ob chav txhaj tshuaj moulding tshuab yog tias ob khub txhaj tshuaj pwm sib koom nrog qhov chaw thiab lub zog ntawm tib lub tshuab txhaj tshuaj, yog li cov khoom lag luam loj tsis tuaj yeem raug txhaj.

Qhov sib txawv ntawm kev txhaj tshuaj molding ob tog txheej txheem thiab cov txheej txheem overmolding

Ob chav txhaj tshuaj molding thiab overmolding yog ob leeg txhaj tshuaj molding, tab sis lawv kuj sib txawv.

1. Tshaj tsis siv cov txheej txheem txhaj tshuaj pwm, tseem hu ua kev lag luam theem nrab molding, yog nqa tawm ntawm kev txhaj tshuaj molding tshuab zoo tib yam. Cov khoom yog tsim nyob rau hauv ob theem. Tom qab cov khoom lag luam raug tshem tawm ntawm ib txheej pwm, nws muab tso rau lwm txheej pwm txhaj dua rau kev txhaj tshuaj molding ob. Yog li ntawd, txhaj tshuaj molding tshuab siv tshuab ib txwm siv rau cov txheej txheem overmolding.

2. Muab ob npaug rau txhaj tshuaj molding yog tias ob yam khoom siv yas txhaj rau tib lub tshuab txhaj tshuaj, ua ob zaug, tab sis cov khoom tsuas yog tawm ib zaug xwb. Feem ntau, cov txheej txheem molding no tseem hu ua ob yam khoom txhaj tshuaj molding, uas feem ntau yog ua tiav los ntawm ob txheej pwm thiab yuav tsum tau siv lub tshuab txhaj tshuaj tshwj xeeb ob npaug.

3. Ob chav txhaj tshuaj molding yog txoj kev hloov txuas ntxiv. Nws tsis muaj kev ua haujlwm ntawm kev coj tawm thiab tso cov ntu hauv nruab nrab, cawm lub sijhawm thiab kev ua yuam kev ntawm qhov rov ua haujlwm, txo tus nqi ntawm cov khoom tsis zoo, thiab txhim kho cov khoom lag luam zoo thiab kev tsim khoom zoo piv nrog cov txheej txheem overmolding.

4. Kev coj tus txheej txheem yog qhov tsim nyog rau kev txhaj tshuaj molding ntawm cov khoom nrog kev ua kom zoo thiab kev txiav txim me me. Txwv los ntawm cov kev ntsuas tshwj xeeb ntawm kev txhaj tshuaj ob npaug tshuab moulding, feem ntau nws tsis haum rau kev txhaj tshuaj molding ntawm qhov loj.

5. Lub muv ua ntej ntawm kev txhaj tshuaj ob pwm yuav tsum zoo ib yam, thiab cov pwm encapsulation tsis muaj qhov yuav tsum tau ua no. Yog li ntawd, qhov tseeb thiab tus nqi ntawm cov txhaj tshuaj pwm ob npaug yog siab dua li ntawm cov txhaj tshuaj txhaj tiv thaiv pwm.

Cov lus qhia ntawm kev txhaj tshuaj molding ob tog txheej txheem:

1. Hauv cov txheej txheem ntawm kev txhaj tshuaj ob-txheej txhaj moulding, muaj plaub qhov tseem ceeb: kev siv lub tshuab txhaj tshuaj ob tog, txhaj ob pwm txhaj, cov khoom siv yas tsim nyog thiab tsim qhov tsim nyog.

2. Cov khoom xaiv ntawm cov mos thiab tawv Roj hmab ob zaug-txhaj Moulding Yuav tsum muaj qee qhov kub thiab txias sib txawv ntawm cov kis ntawm ob hom ntawm cov ntaub ntawv rau ob-xim txhaj tshuaj molding. Feem ntau, nws raug nquahu tias cov ntsiab lus melting ntawm cov khoom txhaj thawj yog siab dua li ntawm cov khoom txhaj koob thib ob, thiab cov khoom siv yaj ntawm thawj qhov kev txhaj tshuaj yuav tsum siab tshaj qhov ntawm cov khoom txhaj tshuaj thib ob.

3. Cov txhaj tshuaj tiv thaiv kab ntawv ntawm cov khoom pob tshab thiab cov pob tshab: cov thawj txhaj yog ua los ntawm cov khoom tsis yog pob tshab, thiab lub koob thib ob yog ua los ntawm cov khoom siv pob tshab. Piv txwv li, cov ntaub ntawv tsis yog pob tshab feem ntau yog PC nrog cov khoom kub, thiab PMMA lossis PC yog siv rau cov khoom siv pob tshab thib ob. PC yuav tsum muaj kev tiv thaiv los ntawm kev txau UV. PMMA tuaj yeem xaiv UV lossis tawv tawv. Yog tias muaj cov cim nyob rau saum npoo, nws yuav tsum xaiv UV.

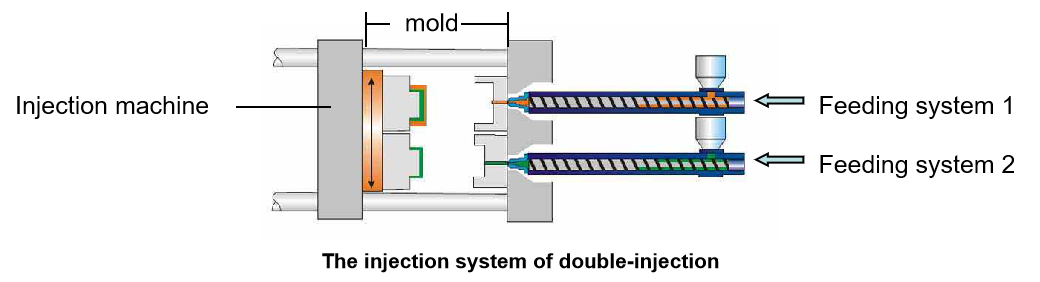

Dab tsi yog ob-txhaj moulding tshuab?

Kev txhaj tshuaj molding tshuab nrog ob txoj kab nruam thiab qhov chaw txhaj tshuaj thiab txoj haujlwm hloov pauv pwm ntawm cov pwm yog hu ua kev txhaj tshuaj molding tshuab, uas yog siv rau ob-xim txhaj tshuaj molding. Kev txhaj tshuaj molding tshuab feem ntau muaj ob hom: cov tshuab txau rau lub tshuab moulding nrog kev txhaj tshuaj ntsia hlau thiab ntsug txhaj tshuaj molding tshuab nrog txhaj ntsia hlau.

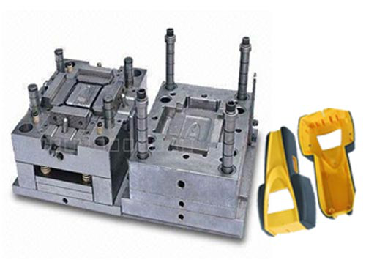

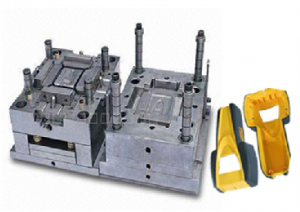

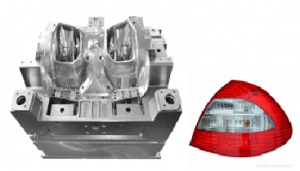

Dab tsi yog ob-txhaj Mould?

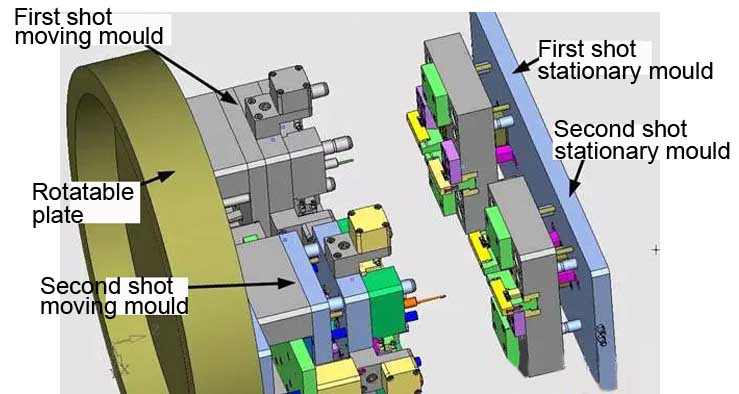

Cov pwm uas txhaj ob yam khoom ua ua ntu zuj zus thiab tsim cov khoom lag luam ob xim hu ua ob-xim pwm. Ob-xim txhaj tshuaj pwm feem ntau yog ob txheej pwm txhaj tshuaj rau ib ntu, sib thooj rau thawj zaug thiab zaum thib ob txhaj raws feem. Tus tuag tom qab (txiv neej tuag) ntawm ob tus neeg tuag ib yam, tab sis hauv ntej tuag (poj niam tuag) txawv.

Kev txhaj tshuaj ob tog pwm yuav tsum muab nruab rau lub tshuab txhaj tshuaj ob zaug txhawm rau txhawm rau tsim cov khoom sib thooj.

Cov lus qhia hauv kev tsim ntawm ob-txhaj ua Pwm

1. Cov tub ntxhais pwm thiab kab noj hniav

Cov txheej txheem tsim ntawm kev txhaj tshuaj ob npaug txhaj pwm yog qhov tseeb tib yam li ntawm kev txhaj tshuaj pwm dav. Qhov sib txawv yog tias cov punch ntawm kev txhaj tshuaj pwm nyob hauv ob txoj haujlwm yuav tsum tau muab suav tias yog tib yam, thiab cov pwm ntawm lub ntsej muag yuav tsum sib koom tes zoo nrog ob qhov punches. Feem ntau, cov khoom seem ntawm cov yas me dua.

IB TUG TXHAJ-KEV TXHAJ TSHUAJ MOULD

2. Kev tawm tsam tshuab

Txij li ob lub xim yas siv tau tsuas yog tom qab kev txhaj tshuaj zaum ob, lub tshuab demoulding ntawm cov khoom siv thawj zaug yuav tsis ua haujlwm. Rau kab rov tav txau tshuab txhaj tshuaj, ejection mechanism ntawm kev txhaj tshuaj tshuab tuaj yeem siv rau ejection ejection. Kev siv lub tshuab ntsug ntsug ntsug, ejection ejection mechanism ntawm lub tshuab txhaj tshuaj tsis tuaj yeem siv. Kev ua haujlwm ua haujlwm ejection ejection ejection tshuab tuaj yeem teeb tsa rau hauv cov lus teb.

3. Kev Tso Cai Sib Xws

Vim tias nws yog lub tshuab txhaj tshuaj ob zaug, cov txheej txheem sib cais tau muab faib ua ib qhov tshuaj txhaj ib leeg thiab cov theem kev txhaj tshuaj, uas yog txhua ntu los ntawm ob lub tshuab txhaj tshuaj.

4, Kev sib txuam ntawm cov pwm puag Vim tias txoj kev txhaj tshuaj ob txoj kev txhaj tshuaj yog qhov tshwj xeeb, nws yuav tsum sib koom tes thiab sib koom tes ua ke, yog li qhov loj thiab qhov tseeb ntawm ob khub ntawm cov cuab yeej tuag yuav tsum zoo ib yam. Rau cov kab rov tav tig txhaj moulds, kaw qhov siab ntawm cov pwm yuav tsum zoo ib yam, thiab qhov chaw nruab nrab ntawm ob lub pwm yuav tsum yog tib lub voos kheej kheej, thiab qhov sib txawv yog 180. Rau ib lub tshuab ntsug txhaj tshuaj moulding tshuab, ob lub pwm ntawm cov pwm yuav tsum tau nyob ntawm tib qho ntsuas.

Kev tsim kho ob-txhaj moulding

Los ntawm cov yam ntxwv thiab daim ntawv thov ntawm ntau cov xim txhaj tshuaj molding thiab dual-material co-molding txhaj tshuaj, nws tuaj yeem pom tias yuav muaj kev hloov maj mam hloov cov txheej txheem tshuaj txhaj tshuaj moulding yav tom ntej. Kev siv tshuab txhaj tshuaj tsis yog tsuas txhim kho qhov tseeb ntawm kev txhaj tshuaj molding cov txheej txheem, tab sis kuj qhib kev ntawm kev txhaj tshuaj molding cov txheej txheem. Kev hloov kho cov khoom siv tshiab thiab cov txheej txheem muaj txiaj ntsig kom tau raws li qhov kev thov nce ntxiv ntawm cov khoom siv sib txawv, ua tiav thiab muaj txiaj ntsig zoo.

Mestech muab ob chav txhaj tshuaj mouldinnng rau ntawm cov tsheb sib txuas, cov khoom siv tes ua lub plhaub, cov lus tsev, cov khawm tseem ceeb, cov leeg thiab lwm yam xim lossis ob yam khoom siv rau xyoo, thov hu rau peb yog tias muaj kev thov.