Pwm (pwm) thiab tuag yog cov cuab yeej los ua cov khoom seem los yog cov khoom nyoos mus rau qhov chaw nrog cov duab tshwj xeeb thiab qhov loj me raws li kev ua ntawm sab nraud quab yuam. Cov cuab yeej no yog tsim ntawm ntau qhov chaw, thiab cov pwm sib txawv yog tsim ntawm ntau qhov chaw. Nws yog kev ua haujlwm uas feem ntau hloov qhov xwm txheej ntawm lub cev ntawm cov khoom kom ua tiav cov duab ntawm qhov khoom. Pwm thiab tuag yog cov cuab yeej siv rau kev ua loj. Daim ntawv thov ntawm cov pwm zoo heev txhim kho kev tsim khoom ntau lawm thiab rov qab tsim cov qhov raug ntawm qhov ntawm. Nws yog lub npe hu ua "niam ntawm kev lag luam".

Pwm thiab tuag yuav muab faib ua ob pawg raws li lawv cov yam ntxwv ua

1. Tuag: daim ntawv thov ntawm ntug lub ntsej muag tuaj yeem ua rau cov khoom sib cais (cais) raws li cov duab sib dhos, lossis khoov tuaj pwm. Qhov kev tuag zoo li no yog siv rau kev hnav, tuag rau lub ntsej muag, lub taub hau txias thiab tawm ntawm qhov chaw.

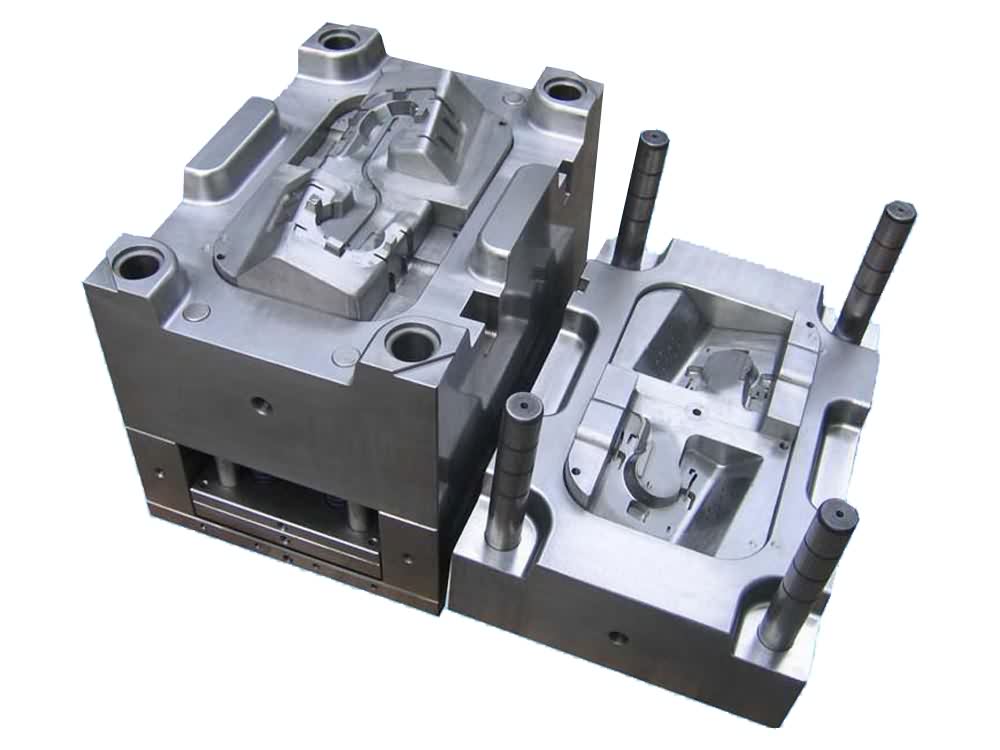

2. Cov pwm: cov khoom siv colloidal lossis kua ua tau txhaj rau hauv cov pwm kab noj hniav, lossis cov khoom siv tau ruaj khov rau hauv cov pwm kab noj hniav, puv thiab txias kom tau txais cov khoom nrog cov khoom zoo ib yam li cov kab noj hniav pwm. Qhov pwm no yog siv rau hauv cov yas ntu txhaj tshuaj molding, silica gel molding, hlau tuag casting. Feem ntau tawm ntawm tus cwj pwm, peb cais cov tuag rau cov hlau tsis zoo xws li aluminium alloy thiab zinc alloy li tuag

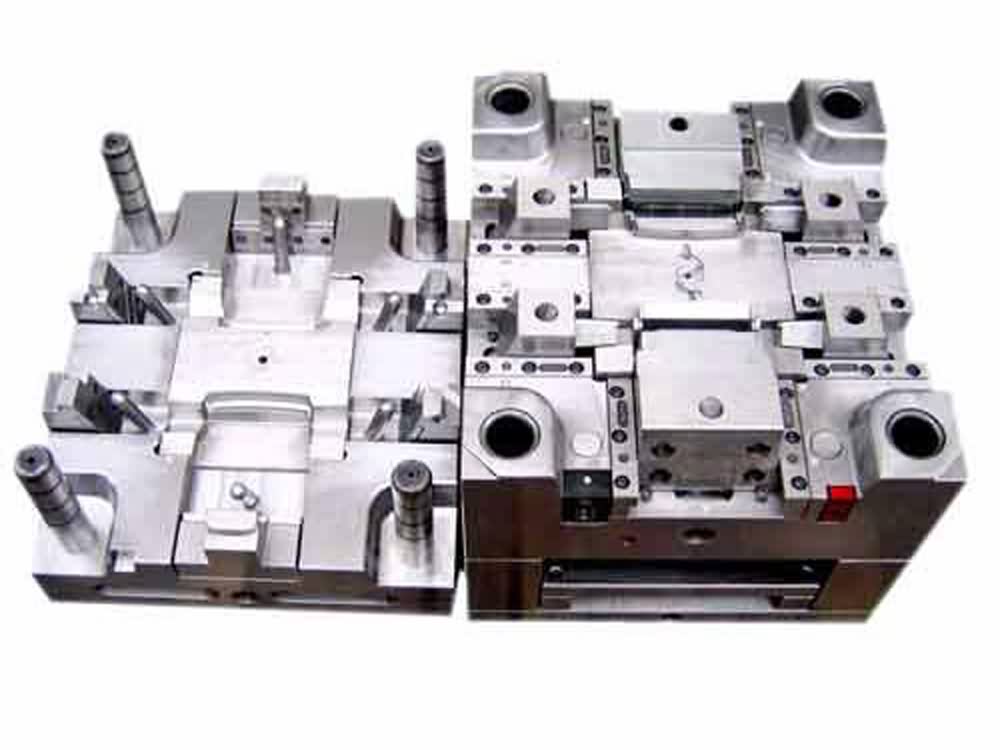

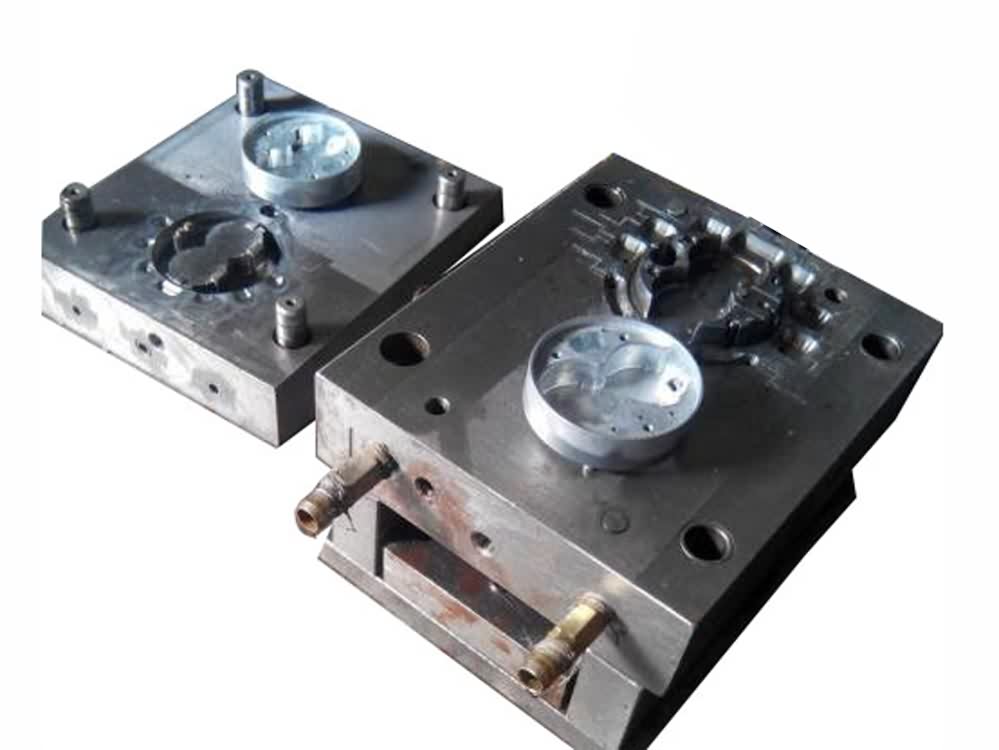

Yas txhaj tshuaj pwm

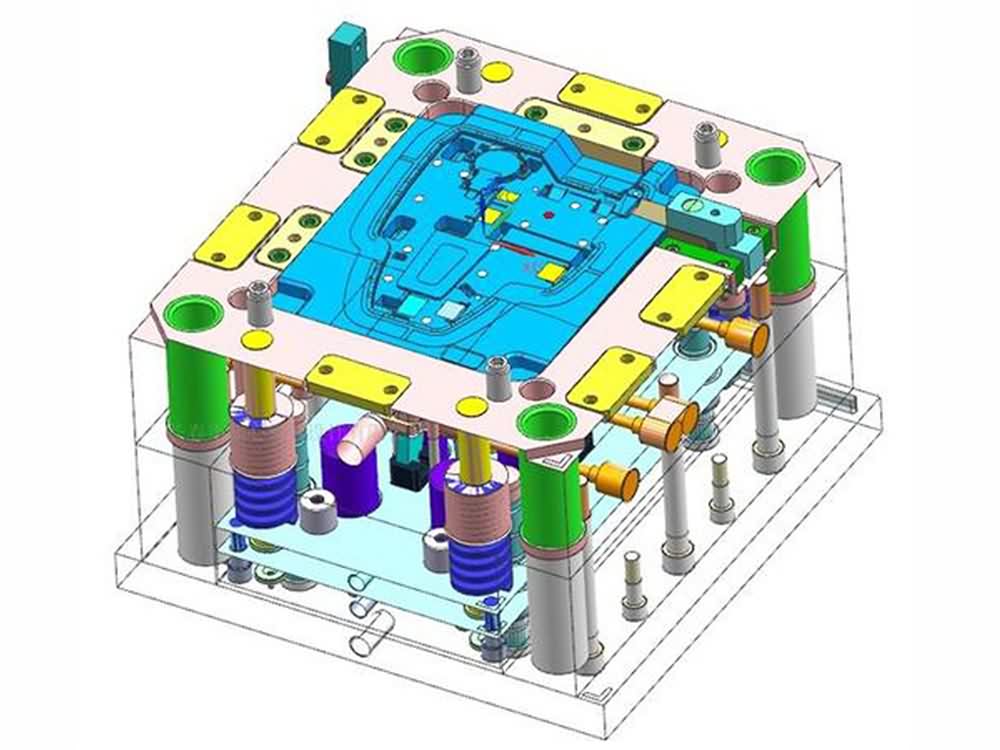

Pwm tsim

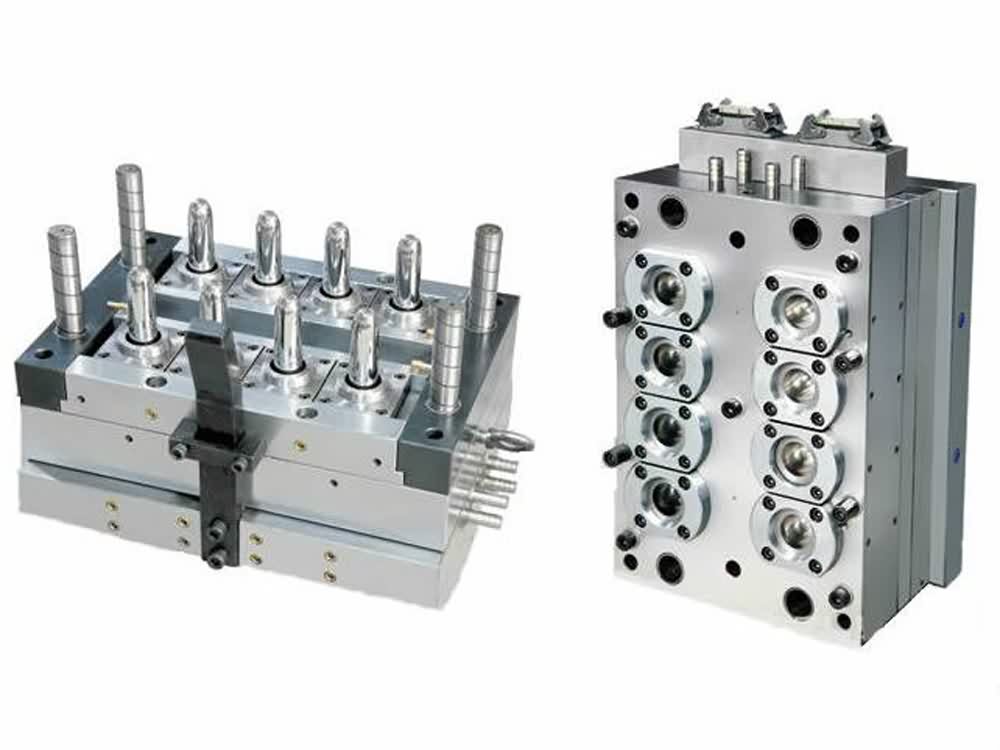

Cov pwm kub khiav pwm

Ntxig molding

Ob chav txhaj tshuaj molding

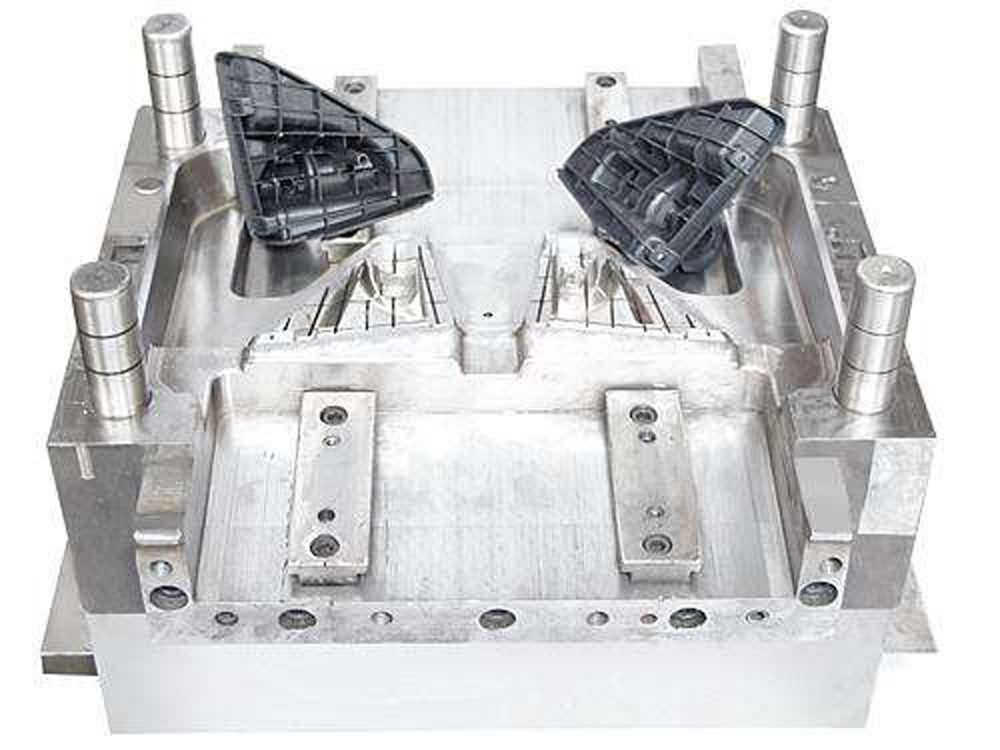

Txhaj tshuaj pwm rau tsheb ntu

Silicone pwm

Tuag casting pwm

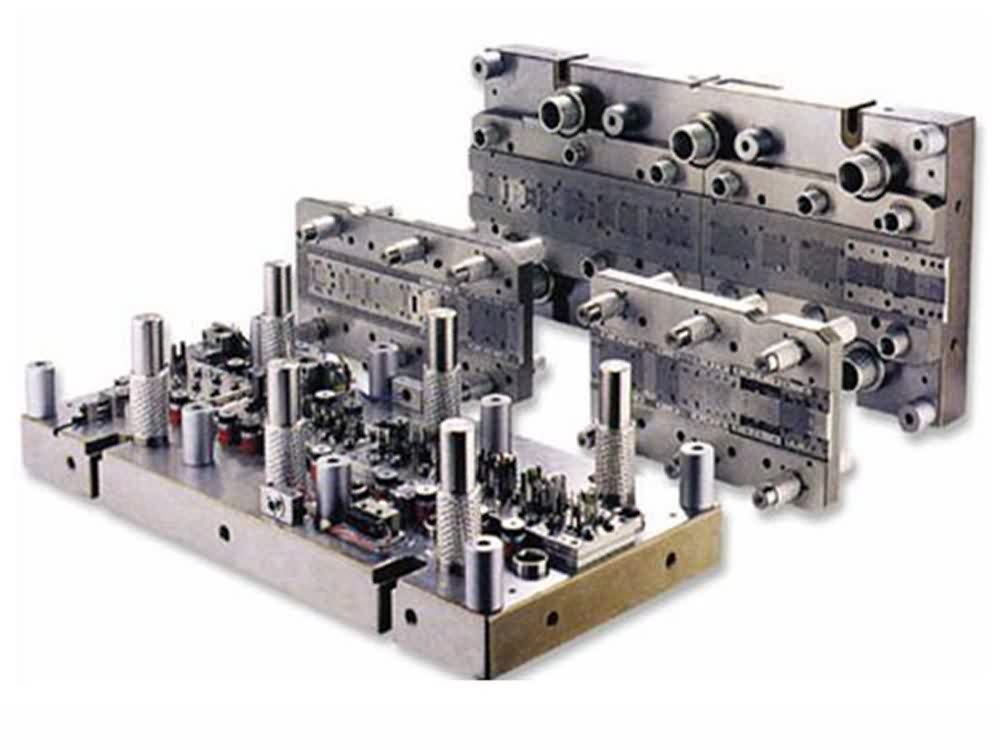

Hlau stamping pwm

HASCO txhaj tshuaj pwm

Raws li cov ntaub ntawv ntawm cov khoom tsim tawm los ntawm pwm, cov pwm raug faib ua:

hlau pwm, yas pwm, thiab pwm ntsej muag.

1.Metal pwm: suav nrog stamping tuag (xws li tuag tuag, khoov tuag, kos duab tuag, flanging tuag, shrinkage tuag, undulating tuag, bulging tuag, shaping tuag, thiab lwm yam), forging tuag (xws li tuag forging tuag, chim siab tuag , thiab lwm yam), extrusion tuag, tuag casting tuag, forging tuag, thiab lwm yam;

2.Nonmetal pwm tau muab faib ua: yas pwm, inorganic tsis yog xim hlau pwm, xuab zeb pwm, nqus plua plav pwm thiab paraffin pwm. Ntawm lawv, nrog txoj kev loj hlob sai ntawm polymer plastics, yas pwm yas ze ze rau tib neeg lub neej. Cov pwm yas tuaj yeem muab faib ua feem ntau: kev txhaj tshuaj molding pwm, extrusion moulding pwm, roj av moulding pwm, thiab lwm yam

Cov pwm thiab tuag muaj ib qhov tshwj xeeb contour lossis kab noj hniav, thiab qhov khoob tuaj yeem sib cais (vov) raws li cov duab contour los ntawm kev siv cov contour duab nrog ntug. Los ntawm kev siv cov duab ntawm cov kab noj hauv sab hauv, qhov seem yuav tuaj yeem tau txais cov duab peb sab kom raug. Tus tuag feem ntau suav nrog ob ntu: tsiv tuag thiab tsau tuag (lossis punch thiab tuag), uas tuaj yeem sib cais thiab kaw. Cov seem tau coj tawm thaum lawv sib cais, thiab seem yog txhaj rau hauv qhov kab noj hniav tuag rau txoj kev ua thaum lawv raug kaw.

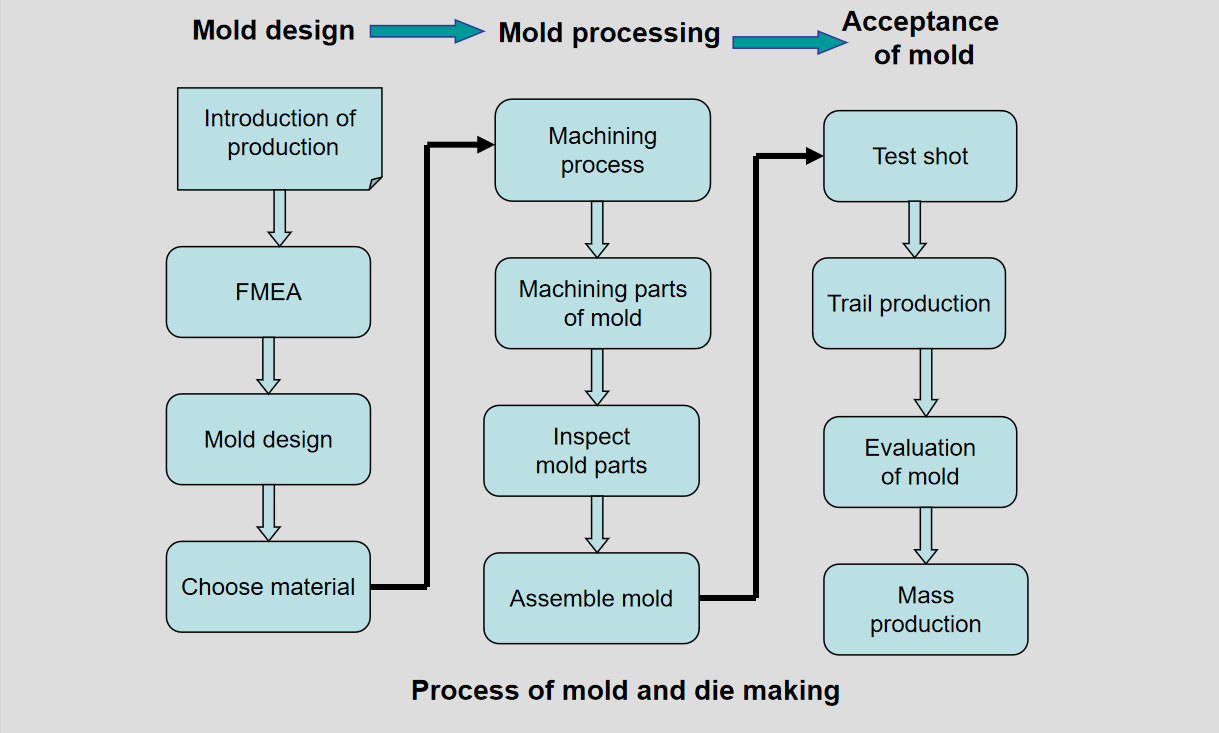

Nws muaj peb theem ntawm kev tsim pwm: 1.Mold tus qauv tsim; 2.muaj cov txheej txheem; 3. Txais kev tuaj pwm

Mestech muab cov qhua tuaj noj mov nrog cov qauv tsim cov yas thiab hlau qhov chaw, kev tsim cov khoom txhaj tshuaj pwm, tuag casting pwm thiab pam pwm pwm. Thiab kev siv cov pwm rau kev tsim loj ntawm cov khoom yas, cov hlau. Peb tab tom nrhiav rau tom ntej ua haujlwm nrog koj los muab koj pwm tsim thiab yas, hlau ua khoom lag luam thiab kev pabcuam.