Yas overmolding

Cov lus piav qhia luv luv:

Yas overmoldingyog cov txheej txheem txhaj tshuaj tshwj xeeb, uas yog siv los txuas ob feem ntawm cov khoom siv rau ib ntu los ntawm kev txhaj tshuaj molding. Ob ntu tau txhaj ob zaug pwm sib txawv hauv cov pwm sib txawv thiab txhaj tshuaj molding tshuab.

Yas dhau los txhaj tshuaj moulding yog txheej txheem tso ib los yog ntau qhov chaw yas ntawm cov khoom siv sib txawv los txhaj tshuaj pwm ua ntej txhaj tshuaj, tom qab ntawv txhaj tshuaj yas rau hauv pwm, cov khoom txhaj npog lossis qhwv qhov chaw ua ntej tsim ua ib ntu.

Thawj kauj ruam: npaj lub qhov tso ua ntej. (Mold1)

Qhov thib ob kauj ruam: tso qhov ua ntej muab tso rau hauv kev txhaj tshuaj pwm, thiab ua dhau-molding nrog cov yas yas. (Pwm2)

Cov lus kawg yas

Muaj ob hom kev tshaj molding

Hom 1: Cov ntu / chaw tso ua ntej yog cov yas, uas tau tsim yav tas los ua lwm yam pwm. Hom no belongs rau ob-txhaj tshuaj txhaj moulding. Qhov no yog yas dhau molding peb tham ntawm no.

Hom 2: Cov seem tso ua ntej tsis yog yas, tab sis tej zaum yuav yog hlau lossis lwm yam khoom seem (piv txwv li cov khoom siv hluav taws xob). Peb hu ua txoj kev no ntxig molding.

Feem ntau ua ntej npaj ua ntej yog qee qhov lossis tag nrho los ntawm cov ntawv txuas ntxiv (cov ntaub ntawv yas) hauv cov txheej txheem dhau-molding.

Koj puas paub daim ntawv thov ntawm cov yas dhau molding?

Muaj ntau lub hom phiaj rau yas dhau kev molding. Qhov feem ntau ntawm lawv yog cov hauv qab no:

1. Ntxiv xim rau kev ua kom zoo nkauj ntsej muag (kom zoo nkauj zoo nkauj).

2. Muab qhov chaw tuav yooj yim ntawm ntu.

3. Ntxiv qhov chaw yoog raws rau qhov chaw yeem txhawm rau txhim kho elasticity thiab kov txoj kev xav.

4. Ntxiv cov khoom siv elastic kom npog cov khoom lag luam lossis lub ntsej muag rau dej-pov thawj.

5. Txuag lub sijhawm sib dhos. Tsis tas yuav txuas cov xov hlau thiab yas tshooj ua ke los yog txiav. Koj tsuas yog yuav tsum muab cov khoom ntaws los tso rau hauv pwm thiab txhaj cov yas. Tsis muaj qhov yuav tsum tau muab sib sau ua ke txhua.

5. Kho ib qho rau sab hauv lwm qhov tsis tas siv fasteners lossis nplaum.

Dab tsi ntawm cov khoom lag luam yas dhau tshuab molding haum rau?

Cov txheej txheem yas dhau txheej txheem yas yog tsim nyog rau ntau cov khoom, uas sib txawv raws li cov kev mob tshwj xeeb ntawm cov khoom. Feem ntau suav nrog txhuam txhuam hniav, siv tes ua haujlwm (xws li siv lub tshuab tsis muaj lub ntsej muag thiab lub hau ntswj me me) thiab cov khoom siv saib xyuas tus kheej (xws li tshuaj zawv plaub hau thiab lub taub hau), cov xov hlau txuas, ntsaws, SIM tuav, thiab lwm yam.

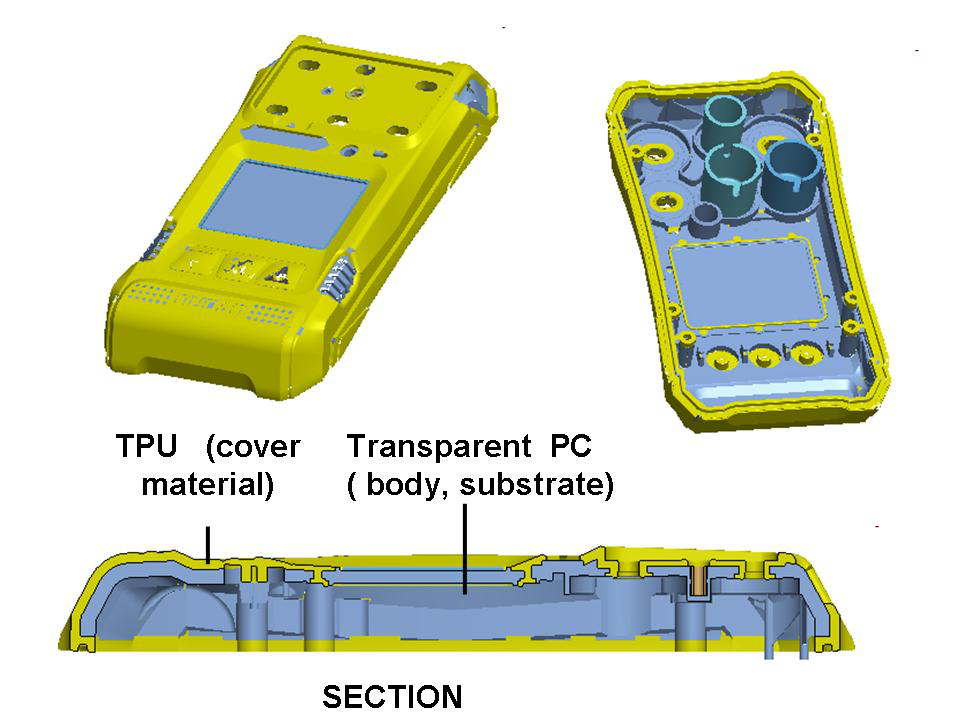

PC & TPU overmolding cov ntaub ntawv tsis dej

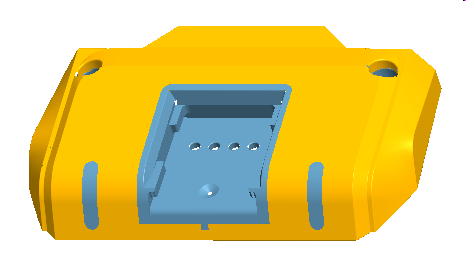

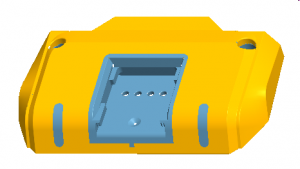

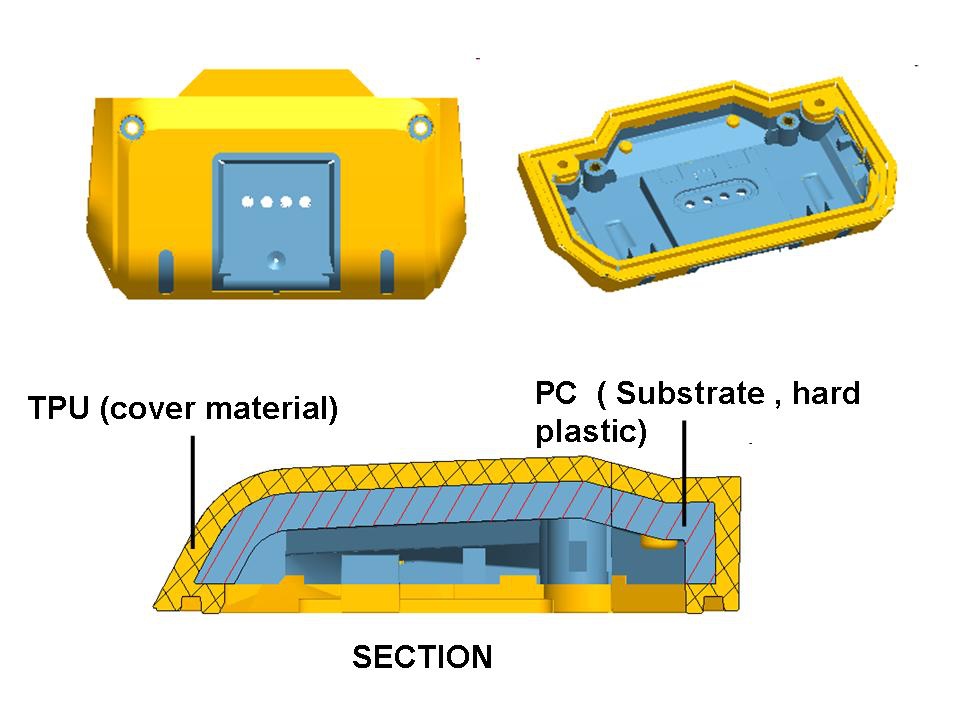

PC & TPU overmolding roj teeb lub qhov rooj

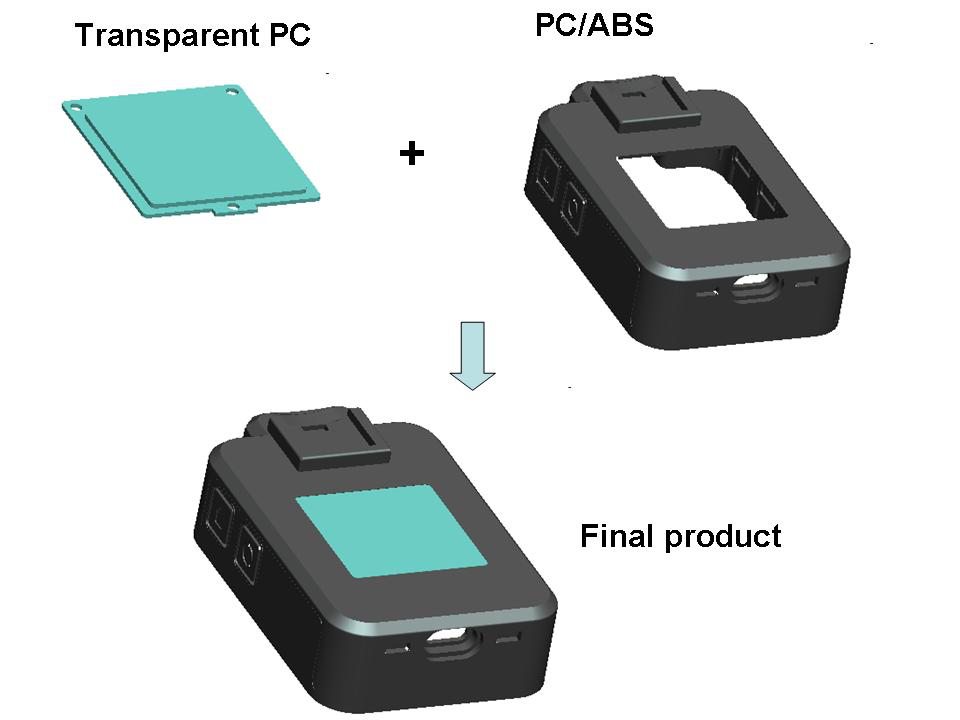

PC & PC / ABS overmolding yas rooj plaub rau cov khoom siv hluav taws xob

PC & TPU overmolding tiv thaiv cov ntaub ntawv rau lub xov tooj ntawm tes

Ob lub xim loj loj loj overmolding yas qhov

ABS & TPE pib sib tshooj lub log

Nov yog qee qhov piv txwv ntawm kev thov molding ntau dua:

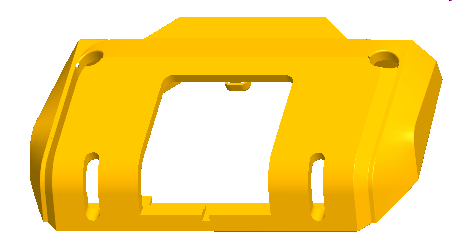

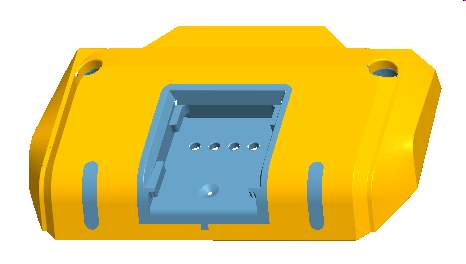

1. Cov tawv yas npog yas - ua ntej ntawm txhua yam, lub hnab yas tsis ruaj khov ua ntej ntu yog tsim. Tom qab ntawv lwm cov yas tawv nws txhaj rau lossis nyob ib ncig ntawm cov ntu ua ntej. Plastics yuav txawv xim thiab / lossis ntxau.

2. Cov yas tawv qhwv hauv cov tawv mos elastomer yas - ua ntej, cov khoom yas tawv yog tso ua ntej. Elastomer cov khoom siv roj hmab (TPU, TPE, TPR) yog tom qab ntawd txhaj tshuaj rau lossis nyob ib puag ncig ntawm cov khoom ua ntej. Qhov no feem ntau yog siv los muab cov khoom muag muag zoo nkauj rau thaj chaw txhav.

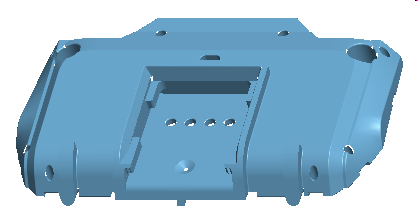

3. Yas qhwv hlau - ua ntej txhua yam, cov hlau puag yog machined, cam khwb cia lossis puab. Tom qab ntawd, cov ntu ua ntej yog tso rau hauv kev txhaj tshuaj pwm kab noj hniav, thiab cov yas yas ua rau sab hauv lossis puag ncig cov hlau. Qhov no feem ntau yog siv los ntes cov hlau hauv cov yas.

4.Elastomer resin npog Cov Hlau - Ua ntej, cov hlau ntu yog tshuab, nrum lossis puab. Cov txheej txheem ua ntej tso rau cov hlau yog tom qab ntawd tso rau hauv kev txhaj tshuaj pwm thiab elastomer resin raug txhaj rau lossis puag ncig cov hlau. Qhov no feem ntau yog siv los muab cov khoom muag muag thiab zoo-tuav.

5. Mos elastomer resin qhwv PCBA lossis cov khoom siv hluav taws xob, lub teeb tsa hluav taws xob, thiab lwm yam

Nws yog ib qho tseem ceeb kom nco ntsoov tias muaj qee qhov kev txwv thiab kev tsis sib haum ntawm cov khoom siv sib txawv uas yuav tsum tau txiav txim siab rau qhov sib txawv. Koj tsis tas rau ob hom khoom siv. Peb tau pom qee yam khoom lag luam, nyob rau hauv ib ntu nrog peb qhov sib txawv yas sib txuas ua ke kom ua tiav ntau xim xim sib puav. Ntawm no yog qhov piv txwv yooj yim ntawm cov khoom lag luam koj yuav paub zoo: txiab.

Feem ntau, cov khoom siv ua ntej lossis cov khoom siv tau muab tso rau hauv kev txhaj tshuaj pwm, thaum lub sijhawm cov yas overmolding yas tau txhaj rau hauv lossis qhov chaw ua ntej. Thaum cov khoom siv txau rau ntawm cov tshuaj tiv thaiv kom txias thiab kho kom zoo, ob cov ntaub ntawv no tau koom ua ke los tsim ib qho tseem ceeb. Cov lus qhia ntxiv: Feem ntau nws yog ib lub tswv yim zoo kom muaj koj cov khoom ua ntej ntawm cov khoom seem thiab cov ntaub ntawv sau cov khoom nqus tes hlau. Hauv txoj kev no, ob qho khoom siv tau los ua ke tsis tsuas yog hauv lub cev xwb, tab sis kuj yog lub cev.

Dab tsi yog qhov zoo ntawm dua molding hauv ntau lawm?

Tshaj pwm moulding muaj cov qauv yooj yim thiab txheej txheem hloov tau.

1. Nws muaj feem xyuam rau cov khoom siv nrog cov npog loj, tshwj xeeb tshaj yog cov seem nrog sib dhos. Qhov hom yas no nyuaj rau kev txhaj tshuaj hauv tib lub tshuab txhaj tshuaj moulding nrog ob-xim pwm, uas tuaj yeem ua tiav los ntawm cov yas txhaj tshuaj txhaj tshuaj.

2. Thaum cov duab ntawm cov yas preset tau yooj yim thiab qhov loj me heev, thiab qhov kawg kawg muaj qhov loj me, nws tsim nyog los saws

yas txhaj tshuaj molding. Lub sijhawm no, cov pwm ntawm lub preset ib feem pwm tuaj yeem ua tau me me lossis ntau kab noj hniav pwm, uas tuaj yeem txo tus nqi pwm ntau.

3. Thaum cov khoom siv ua ntej tso thiab cov khoom siv encapsulated yog txhua yam plastics (resins), nws tau hais tias ob chav txhaj tshuaj molding txheej txheem yuav tsum tau siv rau hauv cov khoom siv ntau lawm siv ntau tshaj kev siv tshuab kom thiaj li tau txais cov khoom lag luam zoo, cov khoom lag luam siab thiab tus nqi qis. Thaum cov tshuab raj me me lossis cov khoom tsim nyog yuav tsum tsis loj, overmolding yuav siv tau kom tsis txhob tso peev ntawm lub tshuab txhaj tshuaj ob zaug thiab tus nqi tsim pwm siab.

Cov ntaub ntawv yog dab tsi ua ntej muab tso ua los ntawm?

Peb hu rau cov ntu ua ntej tso rau hauv pwm cov khoom ua ntej muab tso (lossis qhov chaw uantej tso).

Qhov chaw tso ua ntej tuaj yeem yog cov khoom seem, machined hlau ib feem, pwm yas sab nrauv, lossis txawm tias ib qho khoom lag luam uas twb muaj lawm, xws li cov txiv ntseej, ntsia hlau, lossis cov khoom siv hluav taws xob txuas. Cov seem ua ntej no yuav muab tso ua ke nrog kev txhaj tshuaj tom qab los tsim cov ntu ib qho los ntawm kev ua yeeb yam tshuaj lom neeg thiab kev txuas tshuab. Cov elastomer resins (TPU, TPE, TPR) kuj tseem yog cov yas, tab sis tsis haum rau tau ua ntej qhov chaw.

Yuav ua li cas xaiv cov roj hmab yas rau ntau dua molding?

Cov yas txav siv los ntawm dua molding yog feem ntau yog cov yas. Lawv pib nyob rau hauv daim ntawv ntawm cov hais, thiab lawv lub ntsiab lus melting feem ntau qis dua li ntawm qhov chaw tso ua ntej kom tiv thaiv cov khoom ua ntej los ntawm kev puas tsuaj los ntawm kub. Cov xau no tau muab sib xyaw nrog cov tshuaj pleev xim ntxiv xws li cov xim muaj hau, ua npuas ncauj thiab lwm yam muab tub lim. Tom qab ntawd nws tau rhuab mus rau melting point thiab txhaj rau hauv cov pwm ua kua. Muaj qee qhov kev txwv ntawm cov ntaub ntawv uas tsim nyog rau tshaj molding. Yog tias cov seem ua ntej yog cov khoom siv hlau, koj tuaj yeem siv cov yas ib yam li cov khoom siv dhau. Cov teeb meem sib xyaw tau muaj yog tias qhov seem ua ntej yog ua los ntawm lwm cov khoom siv yas (roj hmab lossis TPE) nrog cov nplauv tsis qab.

Koj puas paub txhaj tshuaj moulding tshuab rau tshaj molding?

Kev txhaj tshuaj molding tshuab siv hauv cov yas dua-txhaj tshuaj yog ib qho kev txhaj tshuaj molding tshuab, uas tau muab faib ua ob hom: ntsug thiab kab rov tav.

1. Ntsug txhaj tshuaj molding tshuab nyob ntau qhov chaw dua li kab rov tav txhaj moulding tshuab ntawm tib lub tonnage, uas tsis yooj yim los tswj, yog li cov tonnage feem ntau me dua. Qhov tsim tshwj xeeb rau qhov loj me me lossis qhov chaw tso ua ntej yuav tsis yooj yim kho hauv cov pwm.

2. Kab rov tav txhaj moulding tshuab muaj tonnage loj loj thiab qhov chaw nyob me me, uas tsim nyog rau kev txhaj tshuaj molding loj qhov loj me.

Yuav ua li cas xaiv cov txhaj tshuaj molding tshuab rau tshaj molding?

1. Ntsug txhaj tshuaj molding tshuab feem ntau yog siv rau qhov chaw me me xws li cov hlau txuas thiab cov txuas, txuas ntsaws fais fab, lo ntsiab muag thiab lwm yam. Cov pwm yas yog qhov yooj yim thiab siv tau.

2. Kab rov tav txhaj moulding tshuab yog siv rau qhov loj qhov loj, uas muaj lub zog txaus thiab yog qhov ua haujlwm zoo.

3. Ob-xim txhaj tshuaj molding yog pom zoo rau qhov chaw ua ntej thiab qhov muab cov khoom siv, tuaj yeem ua tiav zoo dua thiab zoo dua li kev txhaj tshuaj tiv thaiv molding.

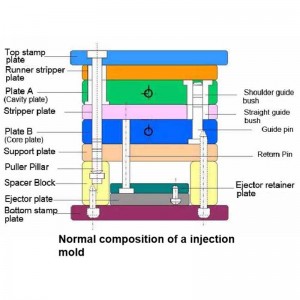

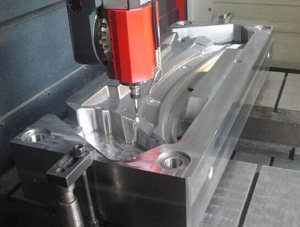

Kev txhaj tshuaj pwm rau ntau dua molding

Overmolding feem ntau muaj ob txheej txhaj tshuaj pwm kub. Ib qho yog rau kev txhaj tshuaj molding ntawm feem ntau tau tso ua ntej, lwm qhov yog rau kev tshaj-molding qhov haujlwm kawg.

Thaum cov tso ua ntej yog cov tsis muaj yas los yog tsis xav tau txhaj tshuaj molding, tsuas muaj ib txheej tsim cov pwm loj. Peb hu ua txoj kev no ntxig molding.

Lub tuam txhab Mestech muaj kev paub txog kev txhaj tshuaj yas rau kev txhaj tshuaj, tshwj xeeb tshaj yog nyob rau hauv cov yas-clad kev txhaj tshuaj ntawm lub plhaub ntawm ntau yam khoom siv hluav taws xob thiab hluav taws xob nrog kho vajtse raws li qhov npaj ua ntej. Mestech tseem muaj nrog ntau yam ob-xim xim txhaj tshuaj tshuab, uas tuaj yeem tsim ntau yam ntawm ob-xim yas ntu, cov yas lo ntawm cov pwm thiab txhaj tshuaj molding. Yog tias koj xav tau, thov hu rau peb.