Tuag casting pwm

Cov lus piav qhia luv luv:

Tuag casting pwmyog ib hom ntawm cov khoom siv rau hlau tuag casting. Ib tus tuag casting pwm muaj pwm "npog tuag ib nrab" thiab lwm tus "ejector tuag ib nrab.

Die-casting pwm yog tsuas yog siv rau kev ua cov txheej txheem ntawm cov hlau tsis muaj txheej txheem nrog cov qauv tsim thiab cov duab. Xws li cov khoom lag luam loj ntau ntawm aluminium alloy, zinc alloy, magnesium alloy thiab tooj hlau alloy qhov chaw, uas feem ntau siv hauv tsheb, khoom siv hluav taws xob, khoom siv hluav taws xob, rooj tog zaum, kho mob thiab lwm yam khoom lag luam.

Dab tsi yog tuag casting pwm

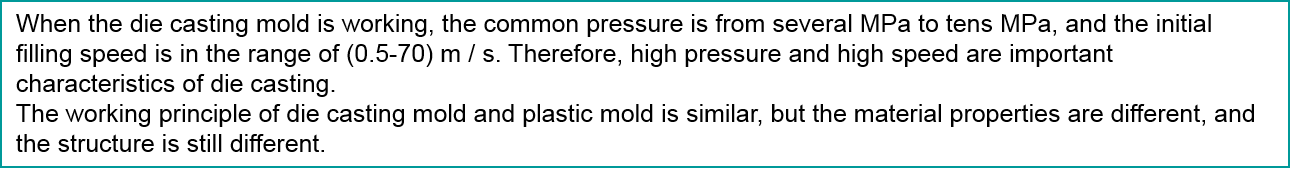

Tuag casting yog lub npe luv ntawm siab casting. Nws yog hom kev ua kom tiav cov kab noj hniav ntawm tuag casting pwm nrog kua los yog semi kua hlau hauv qab siab

ntawm kev kub ceev thiab solidify sai kom tau txais qhov casting. Cov pwm siv yog hu ua kev tuag casting tuag pwm.

Hom kev tuag casting pwm

Raws li kev siv, nws tuaj yeem faib ua cov khoom vaj tsev thiab cov khoom zoo nkauj.

Raws li daim ntawv thov teeb meem, nws muaj peev xwm muab faib ua tsheb tuag casting pwm, 3C khoom tuag casting pwm, khoom ua si tuag casting pwm, thiab lwm yam.

Raws li cov yam ntxwv ntawm cov duab thiab phab ntsa tuab, nws tseem tuaj yeem faib ua nyias-phab ntsa tuag-casting pwm, lub thawv tuag-casting pwm thiab disc tuag-casting pwm.

Tuag casting tshuab, tuag-casting alloy thiab tuag-casting tuag yog qhov peb yam ntawm tuag-casting ntau lawm, ib qho yog qhov tseem ceeb.

Hom kev tuag-casting tshuab, tuag cov qauv txheej txheem, txheej txheem tuag-txheej txheem thiab Hoobkas txheej nyob ntawm cov khoom tuag-casting alloy khoom, yog li kev faib tawm ntawm kev tuag-casting tuag raws li cov khoom siv hlau yog feem ntau tsim rau kev xyaum ntau lawm. lawv tuag-casting pwm tuaj yeem muab faib ua aluminium alloy die-casting pwm, zinc alloy die-casting pwm, magnesium alloy tuag-casting pwm thiab tooj liab alloy die-casting pwm. Cov ntsiab lus muaj raws li hauv qab no:

1) .Txiav ntoo tuag casting pwm

2) .Zej tuag casting pwm

3) .Mag magnesium alloy tuag-casting pwm

4) .Copper alloy tuag-casting pwm

5) .Txoj kev ntsuas pwm

Aluminium tuag casting pwm

Zinc tuag casting pwm

Tuag casting pwm muaj pes tsawg leeg

Cov lus sib xyaw ntawm kev tuag casting pwm tuaj yeem raug muab faib hnyav rau hauv ob ntu:

Ib nrab nyob ruaj ruaj pwm:Txhawm rau txhawm rau tsau ntab ntim pwm ntawm phaj tuag lub tshuab tuag, nrog lub qe txuas nrog lub nozzle lossis chav siab;

Rooj noj tuaj pwm ib nrab:Txhawm rau kom ruaj khov rau ntawm lub phaj mounting ntawm lub tshuab tuag-casting, thiab tsiv nrog lub phaj mounting kom qhib thiab kaw lub pwm. Thaum kaw lub pwm, cov pwm kab noj hniav thiab cov tshuab ua haujlwm tau tsim, thiab cov kua hlau ua kom tiav cov pwm kab noj hniav hauv qab siab. Thaum qhib lub pwm, lub rooj noj mov pwm ib nrab thiab cov pwm nyob ruaj ruaj nres tau sib cais, thiab cov nrum yog thawb tawm nrog kev pab ntawm ejection mechanism teeb ntawm lub txav pwm ib nrab.

Tus txheej txheem tuag-tuag tuag qhia nrog rau cov kab ke ua haujlwm raws li hauv qab no:

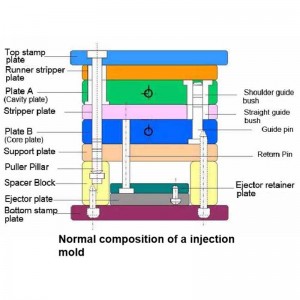

1) Cavity: nto ntuag (lub tes tsho tawg); Tub ntxhais: lub rooj vag sab hauv ntawm qhov chaw sab hauv.

2) Daim ntawv qhia qhov chaw: phau ntawv qhia; coj tes tsho.

3) Tshaj tawm lub tshuab laub qws qws (thimble), rov qab qws, txhim kho pas nrig kho phaj, thawb phaj, thawb phaj qhia ncej, thawb phaj qhia lub tes tsho.

4) Sab hauv rub tawm txoj kev siv Boss, lub qhov (ib sab), cov thaiv thaiv, txwv caij nplooj ntoos hlav, ntsia hlau.

5) Tshaj txheej system Overflow trough, sab lim sab.

6) Cov ntu txhawb.

Nyob ruaj ruaj pwm puag phaj, rooj noj tau pwm lub hauv paus phaj, lub ncoo thaiv (sib dhos, muab tso rau, teeb tsa ua haujlwm).

Qhov sib txawv ntawm qhov tuag casting pwm thiab cov pwm yas:

1. Qhov kev txhaj tshuaj siab ntawm tuag casting tuag yog loj. Yog li ntawd, tus template yuav tsum yog tuab. Tiv thaiv kev deformation.

2. Lub qhov rooj ntawm tuag casting pwm yog txawv los ntawm kev txhaj tshuaj pwm. Kev kub siab ntawm cov khoom ntws kom tau decomposed los ntawm splitter lub khob hliav qab.

3. Lub hauv paus tseem ceeb ntawm kev tuag casting tuag tsis tas yuav tsum ua kom nyuaj. Vim tias qhov ntsuas kub hauv cov kab noj hniav tuag yog dhau 700 ℃. Yog li ntawd, txhua qhov txhaj tshuaj molding yog sib npaug rau ib qhov quenching. Cov kab noj hniav yuav nyuaj thiab nyuab dua. Qhov txhaj tshuaj pwm dav dav yuav tsum tau quenched rau saum toj no hrc52.

4. Feem ntau, cov kab noj hniav ntawm qhov tuag-casting tuag xav tau kev kho mob nitriding. Tiv thaiv cov hlau los txhawm rau txhaws rau lub pwm kab noj hniav.

5. Feem ntau, kev txhim kho corrosion ntawm kev tuag casting tuag yog tus loj. Cov sab saum npoo yog feem ntau bluish.

6. Piv nrog txhaj tshuaj pwm. Qhov haum tau txav tau txav ntawm qhov txav tau ntawm cov tuag casting tuag (xws li cov tub ntxhais rub rub tawm) yuav tsum loj dua. Vim tias qhov ntsuas kub ntawm kev tuag casting txheej txheem yuav ua rau thermal nthuav dav. Yog tias qhov kev tshem tawm tsis loj heev, lub pwm yuav daig.

7. Cov seem ntu ntawm kev tuag-casting tuag muaj ntau dua cov uas yuav tsum tau ua. Vim tias qhov fluidity ntawm alloy yog qhov zoo tshaj li ntawm cov yas, nws yog qhov txaus ntshai heev rau qhov kub thiab kub siab thiab cov khoom siv ua kom siab ntws los ya ntawm qhov chaw.

8. Kev txhaj tshuaj pwm feem ntau cuam tshuam los ntawm thimble. Qhov chaw seem tuaj yeem tso cua. Cov pwm tuag-pwm yuav tsum tau muab nrog lub hnab ntim pa thiab cov hnab ntim sib tsoo (sau cov khoom txias lub taub hau).

9. Kev ua cov ntaub ntawv tsis sib thooj. Kev txhaj tshuaj nrawm ntawm kev tuag casting molding yog nrawm. Thawj theem txhaj tshuaj txhaj siab. Cov yas pwm feem ntau muab faib ua ob peb txhaj tshuaj, siab.

10. Cov pwm tuag-pwm yog ob phaj pwm (Kuv tsis pom muaj peb lub phaj tuag-puab pwm tam sim no) ib qho qhib. Cov khoom tsim qauv sib txawv ntawm cov yas pwm yas txawv. 3 phaj pwm yog hom. Tus lej thiab cov sib lawv liag qhib kev sib phim nrog tus qauv tuag. Square thimble tsis yog feem ntau siv rau hauv kev tuag casting pwm. Lub tog raj kheej.

11. Inclined tus pin (siab kub thiab cov tshuaj zoo fluidity) yog yooj yim rau jam, uas ua rau kom cov pwm tsis khov. Tsis tas li ntawd, cov yas ua yas thiab tuag-casting pwm yog ua los ntawm cov hlau sib txawv; yas pwm feem ntau siv 45 × steel, T8, T10 thiab lwm cov hlau, thaum tuag-casting

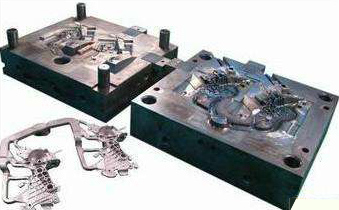

Lub tuam txhab Mestech tsom rau kev ua haujlwm ntawm cov cuab yeej ua haujlwm precision ua pwm thiab qhov chaw ntau lawm rau ntau tshaj 10 xyoo, nrog kev lag luam qib siab thev naus laus zis thiab kev paub txog kev tsim pwm pwm ntau lawm. Lub tuam txhab cov khoom lag luam yog cov khoom lag luam yas lossis cov khoom siv plhaub xws li cov khoom siv hluav taws xob digital, cov khoom siv kho mob, cov khoom siv me nyuam mos, thiab lwm yam, thiab cov khoom lag luam yas xws li cov khoom hauv tsev thiab cov khoom pib. Lub tuam txhab muaj qhov muaj zog muaj peev xwm ntawm cov qauv tsim thiab pwm tsim, uas tuaj yeem muab cov neeg siv tswv yim pom zoo rau cov qauv khoom thiab ntau cov phiaj xwm tsim nyog rau pwm.