ABS cob txhaj moulding

Cov lus piav qhia luv luv:

ABS resin (acrylonitrile butadiene styrene) yog cov tshuaj siv ntau tshaj plaws, thiab ABS resin txhaj tshuaj molding yog qhov ntau tshaj plaws.

Mestech muaj kev paub ntau hauv ABS txhaj tshuaj molding. Peb ABS resin txhaj tshuaj pabcuam tsim cov khoom siv coj los siv rau hauv kev lag luam ntau yam thiab rau ntau yam kev siv. Peb lub xeev-of-the-art cov khoom siv yuav nrawm coj koj txoj haujlwm los ntawm kev pib ua tiav nrog cov txiaj ntsig zoo. Yas ABS cob (Acrylonitrile-Butadiene-Styrene) yog cov tshuaj siv ntau tshaj. ABS yog qhov muaj txiaj ntsig zoo rau nws cov khoom zoo ntawm kev ua haujlwm ruaj khov, qhov ci, ua kom zoo thiab thaj chaw kho Cov Injecton molding yog kev ua haujlwm tseem ceeb rau tsim cov khoom lag luam ABS.Khoom Siv Khoom Siv Lub Cev ntawm ABS resin: Qhov kub siab tshaj plaws: 176 ° F 80 ° C Yam tsawg kawg nkaus kub: -4 ° F -20 ° C Autoclave Muaj Peev Xwm: Tsis muaj taw tes: 221 ° F 105 ° C Lub zog Lub zog: 4,300psi Lub zog: R110 UV Tsis kam: Lub xim tsis zoo: Hloov pauv sib txawv : 1.04  ABS resin Txhaj Tshuaj Moulding Cov Kev Zoo1.Qhov khoom siv hluav taws xob zoo 2.Impact resistance 3.Txoj kev siv tshuaj lom neeg, tshwj xeeb tshaj yog ua rau ntau cov kua qaub, glycerine, alkalis, ntau cov hydrocarbons thiab cawv, cov inorganic ntsev 4.Combines lub zog, rigidity thiab tawv hauv ib qho khoom siv 5.Txoj kev thauj khoom ruaj khov 6. Lub teeb yuag 7.Processing dimensional stability thiab nto gloss yog qhov zoo, yooj yim rau xim, xim, kuj tuaj yeem txau hlau, electroplating, vuam thiab kev sib txuas thiab lwm yam kev ua tiav theem nrab. 8. ABS tuaj yeem ua ntau hom xim raws li cov neeg xav tau. Yog tias ntxiv nplaim taws rov ua kom zoo ntxiv lossis tiv thaiv ultraviolet ntxiv rau ABS, nws tuaj yeem siv los tsim cov khoom siv ntawm cov khoom siv sab nraud lossis qhov kub ib puag ncig.

ABS resin Txhaj Tshuaj Moulding Cov Kev Zoo1.Qhov khoom siv hluav taws xob zoo 2.Impact resistance 3.Txoj kev siv tshuaj lom neeg, tshwj xeeb tshaj yog ua rau ntau cov kua qaub, glycerine, alkalis, ntau cov hydrocarbons thiab cawv, cov inorganic ntsev 4.Combines lub zog, rigidity thiab tawv hauv ib qho khoom siv 5.Txoj kev thauj khoom ruaj khov 6. Lub teeb yuag 7.Processing dimensional stability thiab nto gloss yog qhov zoo, yooj yim rau xim, xim, kuj tuaj yeem txau hlau, electroplating, vuam thiab kev sib txuas thiab lwm yam kev ua tiav theem nrab. 8. ABS tuaj yeem ua ntau hom xim raws li cov neeg xav tau. Yog tias ntxiv nplaim taws rov ua kom zoo ntxiv lossis tiv thaiv ultraviolet ntxiv rau ABS, nws tuaj yeem siv los tsim cov khoom siv ntawm cov khoom siv sab nraud lossis qhov kub ib puag ncig.

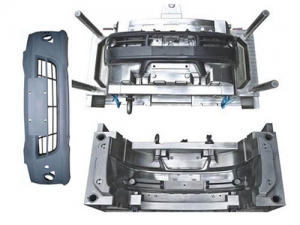

Daim ntawv thov ntawm cov yas ABS yasABS muaj nws tus hneev taw nyob rau hauv ntau daim ntawv thov vim nws txoj kev ua tau zoo thiab kev muaj peev xwm ua tau zoo. Cov ntsiab lus tseem ceeb muaj raws li hauv qab no: 1. Kev Lag Luam Tsav Tsheb Ntau qhov chaw hauv kev lag luam tsheb yog tsim los ntawm ABS lossis ABS alloys. Piv txwv li: lub tsheb khiav ceev, lub cev sab nrauv sab nrauv, sab hauv vaj huam sib luag kho kom zoo nkauj, lub kauj, lub suab rwb thaiv tsev vaj huam sib luag, lub qhov rooj kaw, pob zeb, cua tshuab yeeb thiab lwm yam khoom ntxiv ABS tau siv dav hauv kev kho kom zoo nkauj sab hauv ntawm lub tsheb, xws li lub hnab looj tes lub thawv thiab sundry box Assembly ua los ntawm kev kub hnyiab ABS, lub qhov rooj dav dav thiab cov khoom siv qis dua, lub ntsej muag dej tank yog ua los ntawm ABS, thiab ntau lwm yam ua los ntawm ABS ua cov khoom raw. Qhov nyiaj ntawm ABS qhov siv hauv tsheb yog kwv yees li 10 kg. Ntawm lwm cov tsheb, qhov ntau ntawm ABS feem siv kuj yog qhov txaus ntshai heev. Cov ntu tseem ceeb ntawm lub tsheb yog tsim los ntawm ABS, xws li dashboard nrog PC / ABS raws li lub cev pob txha, thiab saum npoo yog ua los ntawm PVC / ABS / BOVC zaj duab xis. 2. Cov Khoom Siv Hluav Taws Xob thiab Khoom Siv Hluav Taws Xob ABS tau yooj yim nkag rau hauv lub khauj khaum thiab qhov chaw ua ntu nrog cov qauv yooj yim, ruaj khov thiab qhov tsos zoo nkauj. Yog li, ABS tau siv dav hauv cov khoom siv hauv tsev thiab khoom siv me me, xws li TV teeb tsa, tshuab kaw lus, tub yees, tub yees, tshuab ntxhua khaub ncaws, lub tshuab cua txias, tshuab nqus tsev, tshuab fev hauv tsev, kaw suab thiab VCD. ABS tseem siv dav hauv cov nqus tsev nqus thiab ua tau los ntawm ABS tseem siv hauv cov tais diav hauv chav ua noj. ABS cov khoom txhaj tso tawm rau ntau dua li 88% ntawm tag nrho cov khoom siv yas hauv tub yees. 3. Cov Khoom Siv Ua Haujlwm Vim tias ABS muaj lub ntsej muag siab thiab yooj yim molding, chaw ua haujlwm cov tshuab thiab tshuab xav tau cov tsos zoo nkauj thiab coj tau zoo, xws li rooj plaub xov tooj, rooj plaub nco qab, lub computer, fax tshuab thiab theej tawm, ABS qhov chaw tau siv dav. 4.Cov khoom siv tiv thaiv vim hais tias ABS muaj cov molding ua tau zoo, nws muaj txiaj ntsig los ua cov khoom siv chassis thiab lub plhaub nrog qhov loj me, deformation me me thiab ruaj khov loj. Xws li kev khiav haujlwm dashboard, lub rooj ua haujlwm, lub pas dej ua kua, qhov chaw thawv, thiab lwm yam.

Cov khoom lag luam thiab pwm tsim

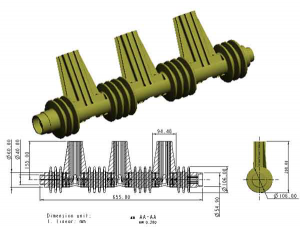

1. Phab ntsa tuab ntawm cov khoom: Phab ntsa tuab ntawm cov khoom muaj feem xyuam nrog qhov ntev ntawm yaj yaj, ntau lawm kev ua tau zoo thiab siv cov kev xav tau. Qhov ntsuas ntawm qhov siab tshaj plaws ntws ntev ntawm ABS yaj rau cov phab ntsa tuab ntawm cov khoom yog kwv yees li 190: 1, uas hloov raws qib. Yog li ntawd, cov phab ntsa tuab ntawm ABS cov khoom lag luam yuav tsum tsis txhob ua heev dhau. Rau cov khoom xav tau kev kho mob electroplating, lub phab ntsa thickness yuav tsum yog me ntsis tuab dua kom thiaj li ua kom cov nplaum ua tiav ntawm cov xim txheej thiab saum npoo ntawm cov khoom. Vim li no, cov tuab phab ntsa ntawm cov khoom yuav tsum tau xaiv ntawm 1.5 thiab 4.5 hli. Thaum xav txog cov phab ntsa tuab ntawm cov khoom, peb kuj yuav tsum them sai sai rau kev sib txawv ntawm cov phab ntsa tuab, tsis txhob sib txawv loj heev. Rau cov khoom lag luam uas yuav tsum tau electroplated, qhov saum npoo yuav tsum tiaj tus thiab tsis-convex, vim tias cov khoom no yooj yim txhawm rau plua plav vim cov nyhuv electrostatic, ua rau lub hauv paus tsis zoo ntawm cov xim txheej. Ntxiv rau, qhov muaj nyob ntawm cov ces kaum ntse ntse yuav tsum zam kom tsis txhob muaj kev kub ntxhov. Yog li ntawd, nws yog qhov tsim nyog kom xav tau arc kev hloov ntawm tig kaum, tuab pob qij txha thiab lwm qhov chaw.

2. Demoulding nqes hav: Qhov nqes hav demoulding ntawm cov khoom yog cuam tshuam ncaj qha rau nws cov shrinkage. Vim tias cov qib sib txawv, cov duab sib txawv ntawm cov khoom lag luam thiab cov sib txawv sib txawv ntawm cov qauv, txoj kev ua shrinkage muaj qee qhov sib txawv, feem ntau hauv 0.3 0.6%, qee zaum nce txog 0.4 0.8%. Yog li no, qhov tseeb ntawm kev ua qhov ntev ntawm cov khoom lag luam yog siab. Rau cov khoom lag luam ABS, qhov nqes hav ntawm demoulding yog suav tias yog raws li hauv qab no: qhov tseem ceeb yog 31 qib raws qhov kev taw qhia demoulding, thiab kab noj hniav feem yog 1 degree 20'along qhov taw qhia demoulding. Rau cov khoom lag luam nrog cov qauv duab lossis nrog cov tsiaj ntawv thiab cov qauv, txoj kab ntawm toj yuav tsum tau nce ntxiv kom tsim nyog.

3. ejection yuav tsum: vim hais tias qhov pom meej ua tiav ntawm qhov khoom muaj qhov cuam tshuam ntau dua rau kev ua haujlwm ntawm electroplating, qhov zoo li ntawm qhov txawv me me yuav pom tseeb tom qab electroplating, yog li ntxiv rau qhov uas yuav tsum tsis muaj nti nyob hauv kab noj hniav tuag, thaj chaw ntawm ejection yuav tsum loj, qhov kev sib txuas ua ke ntawm kev siv ntau lub ejectors hauv txheej txheem ejection yuav tsum yog qhov zoo, thiab lub zog ejection yuav tsum zoo ib yam.

4. Kev Tawm Nrawm: Txhawm rau tiv thaiv cov pa phem thaum lub sijhawm ua cov txheej txheem, hlawv cov yaj thiab cov kab uas pom tseeb, nws yuav tsum qhib lub qhov cua lossis lub qhov dej kom muaj qhov tob tshaj li 0.04 hli kom pab txhawb kev tso tawm cov roj ntawm lub yaj nti. 5. Qhov khiav thiab lub rooj vag: Txhawm rau ua kom ABS yaj ua rau tag nrho cov seem ntawm cov kab noj hniav kom sai li sai tau, txoj kab uas hla ntawm tus khiav yuav tsum tsis pub tsawg dua 5 hli, qhov tuab ntawm lub rooj vag yuav tsum ntau tshaj 30% ntawm cov tuab ntawm cov khoom, thiab qhov ntev ntawm sab ncaj (xa mus rau ntawm feem uas yuav nkag mus rau hauv kab noj hniav) yuav tsum yog li 1 hli. Txoj haujlwm ntawm lub rooj vag yuav tsum txiav txim siab raws li qhov xav tau ntawm cov khoom thiab cov kev taw qhia ntawm cov khoom ntws. Yob tsis pub muaj nyob rau ntawm txheej txheej rau cov khoom uas xav tau electroplated.

Kho deg thiab kho kom zoo nkaujABS yog ib qho yooj yim hauv cov xim thiab xim. Nws tseem tuaj yeem raug txau nrog hlau thiab electroplating. Yog li ntawd, ABS ntu feem ntau kho kom zoo nkauj thiab tiv thaiv los ntawm zas txhaj tshuaj molding thiab txau, luam ntawv lo lo ntxhuav, tshuab hluav taws xob thiab kub kub lub cev rau qhov chaw ntawm molding qhov. 1. ABS muaj cov cwj pwm txhaj tshuaj zoo, thiab tuaj yeem tau txais ntau qib ntawm cov nplej, huab, du thiab iav saum npoo los ntawm kev tuag. 2. ABS muaj cov xim zoo nkauj, thiab nws yooj yim kom tau txais ntau yam xim xim los ntawm kev txau saum npoo. Thiab tshuaj ntsuam luam tawm ntau yam cim thiab qauv. 3. ABS muaj qhov zoo electrochemical plating yam ntxwv thiab yog tib lub plastics uas tuaj yeem yooj yim tau cov hlau saum npoo los ntawm electroless plating. Electroless plating txoj kev suav nrog electroless tooj liab plating, electroless npib tsib xee plating, electroless nyiaj plating thiab electroless chromium plating.