Ntxig molding

Cov lus piav qhia luv luv:

Ntxig moldingyog cov txheej txheem yas txhaj tshuaj yas qhov twg cov yas txhaj tshuaj rau hauv kab noj hniav thiab ib ncig ntawm ib qho ntxig qhov lossis tej qhov tso tso rau hauv tib kab noj hniav ua ntej txhaj tshuaj. Cov khoom tsim ntawm cov txheej txheem no yog ib thooj nrog cov ntxig lossis ntxig encapsulated los ntawm cov yas.

Ntxig moldingyog cov txheej txheem yas txhaj tshuaj yas qhov twg cov yas txhaj tshuaj rau hauv kab noj hniav thiab ib ncig ntawm ib qho ntxig qhov lossis tej qhov tso tso rau hauv tib kab noj hniav ua ntej txhaj tshuaj. Cov khoom tsim ntawm cov txheej txheem no yog ib thooj nrog cov ntxig lossis ntxig encapsulated los ntawm cov yas.

Ntxig moulding nthuav tawm lub peev xwm ntawm cov yas thiab tuaj yeem pab txo tus nqi ntawm cov khoom los ntawm kev txwv tus nqi ntawm cov nqi hlau uas tsim nyog los tsim cov khoom lag luam. Cov ntawv ntxig tuaj yeem ua los ntawm cov hlau lossis lwm lub hnab yas. Hom kev txhaj tshuaj no pib tsim los tso cov kab xov rau hauv cov pwm thiab kom cov xov hlau txuas rau txoj hlua hluav taws xob.

Peb txuas ntxiv cov txheej txheem molding no kom ua tiav tej yam uas lwm cov pwm tsis tuaj yeem lossis tsis ua.

Ua raws li qhov loj me ntawm feem, ntau kab noj hniav pwm tuaj yeem tsim khoom lag luam kom nce ntau lawm. Kev ua haujlwm siab tom qab pwm yog qee zaum yuav tsum tau ua tiav cov khoom sib dhos.

Ntxig moulding yog cov txheej txheem molding uas cov pwm siv los txhaj cov khoom ntxig rau hauv cov ntawv ntxig nrog cov khoom sib txawv, thiab cov khoom siv yaj yog ua ke nrog cov ntxig rau tsim cov khoom sib xyaw. Cov khoom seem yog feem ntau yog hlau qhov, tab sis kuj daim ntaub, ntawv, hlau, yas, iav, ntoo, hlau nplhaib, qhov hluav taws xob.

Cov txheej txheem nta ntawm Insert molding muaj raws li hauv qab no:

1. Nws yog qhov yuav tsum xav txog kev sib xyaw ua ke thiab ntxiv ntawm cov resin ua cov qauv yooj yim, khoov, hlau tsis nruj, lub zog thiab kub tsis kam, thiaj li ua rau txoj kev ua kom zoo nkauj thiab zoo nkauj hlau yas ua ke.

2. Qhov tshwj xeeb, kev sib xyaw ntawm cov khoom siv rwb thaiv tsev thiab cov khoom siv hlau tau siv, thiab cov khoom tsim tau tuaj yeem ua tiav cov haujlwm yooj yim ntawm cov khoom hluav taws xob.

3. Cov ntawv ua ntej ua ke ntawm ntau cov kab ntxig ua rau tus ncej tshaj tawm ntawm cov khoom sib txuam ua ke tsim nyog tshaj.

4. Tso cov khoom tsis yog rau cov hlau, tab sis kuj yog ntaub, ntawv, hlau, yas, iav, ntoo, kauj, qhov hluav taws xob, thiab lwm yam.

5. Rau cov khoom siv ua lub ntsej muag moulding thiab dabtsi yog khoov yooj yim moulding khoom ntawm cov roj hmab sealing puag phaj, txoj haujlwm nyuaj ntawm kev npaj cov nplhaib sib khi tuaj yeem zam tau tom qab cov khoom sib txuam ua los ntawm kev txhaj tshuaj molding rau ntawm txheej, uas ua rau kev sib txuas tsis siv neeg cov txheej txheem tom qab yooj yim dua.

6. Vim tias nws yog qhov sib koom ua ke ntawm cov khoom siv hlau thiab cov hlau ntxig, qhov sib txawv nruab nrab ntawm cov hlau ntxig tuaj yeem tsim qauv nqaim thiab molding kev ntseeg tau ntawm cov khoom lag luam muaj ntau dua qhov uas tau nias hauv molding ..

7. Xaiv cov ntaub nplaum uas tsim nyog thiab molding, uas yog, rau cov khoom lag luam uas yooj yim rau kev puas ntsoog (xws li iav, coil, qhov hluav taws xob, thiab lwm yam), lawv kuj tuaj yeem raug kaw thiab kho ua los ntawm cov cob.

8. Nrog kev sib xyaw ntawm ntsug txhaj moulding tshuab thiab thev txheej, tag nrho cov txheej ntxig thiab lwm yam, feem ntau ntawm kev ntxig molding tej yaam num tuaj yeem paub tsis zoo no feem ntau lawm.

9. tom qab qhov kev tsim ntxig tau tsim, nws tseem tuaj yeem ua rau cov khoom lag luam nrog hollow grooves tom qab cov tub ntxhais qhov kev tshem tawm.

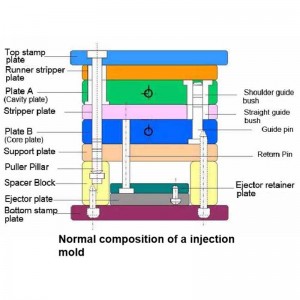

Cov lus qhia ntawm cov feem tsim thiab pwm ntawm ntxig molding

1. Cov khoom yuav tsum muaj rau kev ntxig: hardness, melting point, rigidity, shrinkage

2. Seb cov duab thiab cov loj ntawm cov ntxig yog yooj yim rau kev nqa, tso thiab tso rau. Kev tsim qauv ntawm qhov yuav tsum yooj yim rau kev teeb tsa thiab kev kho nyob rau hauv pwm kom tiv thaiv cov ntu ntawm kev sib txawv lossis txo qis hauv qhov cuam tshuam ntawm cov khoom ntws.

3. Kev tsim tawm qhov tseeb thiab kev ua haujlwm ntawm kev ntxig

4. Xaiv cov qauv pwm uas tsim nyog, thiab cov ntxig tseem tuaj yeem raug muab ntim rau hauv cov cob.

5. Cov ntaub ntawv shrinkage ntawm cov hlau ntxig yog yooj yim kom tsis sib npaug. Qhov ntsuas tsis pub tsawg ntawm cov duab thiab qhov loj me qhov tseeb ntawm cov ntu tseem ceeb yuav tsum tau ua ua ntej.

6. Thaum lub sijhawm txheej txheem txhaj, cov hlau ntxig tau yooj yim rau kev deform thiab hloov chaw, yog li cov pwm muaj pes tsawg leeg thiab tsim cov pwm cov duab uas yooj yim los tswj cov hlau ntxig yuav tsum tau ua tib zoo xav. Rau cov khoom uas nws cov duab ntxig tsis tuaj yeem hloov tau, kev ntsuas ua ntej yog qhov tseem ceeb.

7. Paub meej tias cov hlau ntxig yuav tsum tau muab kho ua ntej lossis ziab khaub ncaws. Lub hom phiaj yog ua kom cov khoom zoo thiab sib sau ruaj khov.

Daim ntaub ntawv raug:

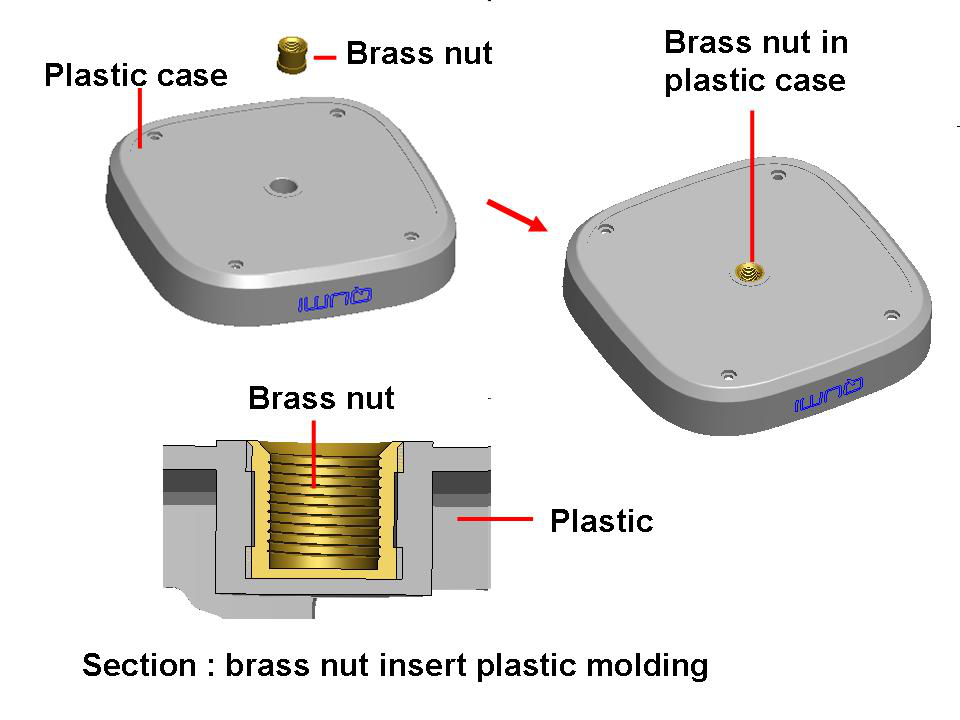

Hlau ntxig molding Hlau ntxig molding yog cov feem ntau siv cov ntxig molding txheej txheem.

Hlau ntxig molding yog ib hom qauv los kho cov hlau ntxig rau hauv kev tsim nyog hauv cov pwm ua ntej, thiab tom qab ntawd txhaj cov yas rau molding. Tom qab lub pwm qhib, qhov tso tawm tau muab qhwv rau hauv cov khoom los ntawm kev txias thiab solidifying yas kom tau txais cov khoom nrog ntxig xws li xov nplhaib thiab electrode.

Nws yog qhov yuav tsum tau hais tias seem ntawm cov kab hlau txuas ntxiv yuav tsum muaj tus qauv tsim nyog thiab tuab, thiab cov seem ntawm cov kab ntaws rau hauv cov pwm tuaj yeem ua haujlwm sai thiab ntseeg tau los tiv thaiv cov yas los ntawm ntws mus rau qhov kho qhov. Cov lus ntxig kuj yuav tsum tau tsim tshwj xeeb, xws li knurling, grooving, sib ntswg, thiab lwm yam nyob rau hauv cov chaw ntim kom lawv ntseeg tau txhim kho nyob rau hauv cov yas sab hauv.

Customized hlau ntxig molding seem:

Mestech yog ib daim ntawv thov tshwj xeeb ntawm kev ntxig molding .. Thov hu rau peb los pab koj nrhiav qhov tseeb qhov ntxig molding tshuaj rau koj daim ntawv thov.

Lub hwj chim ntsaws ntxig txhaj tshuaj molding

Tooj liab txiv ntoo ntxig molding tshuab

Precision hlau phaj ntxig molding