Hlau qauv

Cov lus piav qhia luv luv:

Cov qauv hlau yog ib txwm ua rau cov engineers kom paub tseeb txog kev tsim cov cuab yeej lossis tshuab. Mestech muab hlau thaiv kev tsim khoom ntawm cov neeg yuav khoom.

Hlau qauvyog ib txwm ua rau cov engineers los xyuas cov qauv tsim ntawm lub cuab yeej lossis tshuab. Mestech muab hlau thaiv kev tsim khoom ntawm cov neeg yuav khoom.

Cov khoom siv hlau yog feem ntau siv los ua cov khoom pov thawj thiab cov plhaub khoom siv, thiab lawv cov nqi kim dua li ntawm cov khoom seem yas. Txhawm rau txhawm rau txhim kho tus qauv thiab txo qhov phom sij, nws yog qhov yuav tsum tau ua qauv ntawm cov qauv rau kev tsim qauv thiab ua cov txheej txheem pov thawj ua ntej kev tsim khoom.

Cov khoom siv hlau yog siv dav hauv ntau yam tshuab thiab khoom siv. Lawv feem ntau yog siv los ua precision qhov chaw vim lawv qhov ntev ruaj khov, lub zog thiab tawv, cov yam ntxwv kub thiab tsis kub thiab hluav taws xob, uas ua tau zoo tshaj rau cov khoom seem yas.

Piv nrog rau cov khoom seem yas, muaj ntau yam khoom siv rau cov khoom siv hlau, xws li txhuas alloy, tooj liab, zinc alloy, steel, titanium alloy, magnesium alloy thiab hais txog, nrog cov khoom sib txawv. Ntawm lawv, ferroalloys, alloys alloys, tooj hlau tooj liab thiab zinc alloys feem ntau siv rau hauv kev lag luam thiab cov khoom lag luam. Cov ntaub ntawv hlau no muaj cov khoom siv lub cev thiab tshuaj sib txawv, thiab kev siv tshuab ntawm cov khoom hlau nrog cov qauv sib txawv thiab cov duab tsis sib txawv.

Raws li cov khoom siv thiab cov qauv ntawm qhov, muaj ntau yam ntawm cov khoom siv loj tsim cov txheej txheem rau cov khoom siv hlau, xws li txiav, tuag casting, pam, calendering, khoov, extrusion thiab sintering. Rau qhov tuag-casting, blanking, extrusion thiab sintering, tuaj pwm siv. Cov pwm feem ntau txhais tau tias kev siv nyiaj siab dua, yog li kev txiav cov tshuab feem ntau yog siv rau lawv qhov qauv ua.

Muaj peb txheej txheem loj los ua cov qauv hlau:

1. Machining.

Mas siv rau qhov uas muaj qhov loj qhov me thiab qhov me me.

Cov cuab yeej tseem ceeb yog CNC milling tshuab, tshuab dhos, grinder, EDM, WEDM thiab lwm yam cuab yeej tshuab.

Rau kev ua cov dav hlau, saum npoo, zawj thiab lub qag, lub tes tsho, disk, cuboid thiab nkhaus saum hlau qhov chaw.

Cov cuab yeej siv tshuab tshwj xeeb raug siv los ua cov khoom siv nrog qhov siab qhov ua tau. Qhov chaw xws li cov iav, ntsia hlau pas nrig, thiab lwm yam.

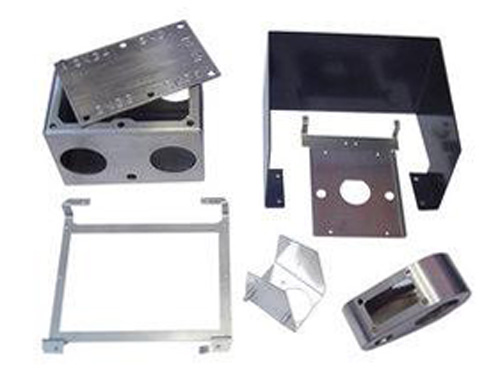

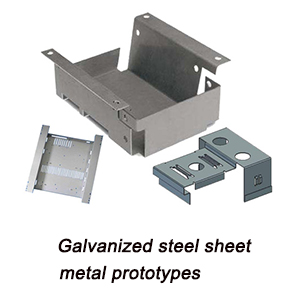

2. Ntawv hlau ua lag luam

Rau lub plhaub thiab npog cov qauv nrog cov phab ntsa nyias thiab tib cov tuab qhov txhia chaw, cov ntawv hlau cov txheej txheem feem ntau siv, uas yog, los ntawm txhais tau tias ntawm laser txiav tshuab thiab qee cov cuab yeej yooj yim lossis cov cuab yeej los ntawm khoov, txiav, stamping thiab rauj. Nws tsuas yog nyob ntawm phau ntawv ntau lawm.

Piv txwv, tsheb vaj tsev, khoos phis tawj nyob rau hauv.

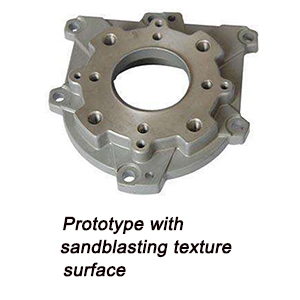

3. Sab Tom Qab Kev Kho Mob

Tom qab cov tshuab los yog ntawv ua hlau, cov qauv tsim qhov ntev thiab cov duab tau txais. Yuav kom tau txais cov khoom zoo thiab zoo nkauj, qhov kev kho saum npoo yog feem ntau xav tau.

A. Cov npoo tiav: sib tsoo, polishing, texturing, laser carving thiab embossing.

B. Kev txau cov hmoov, electroplating, oxidation thiab pleev xim.

Aluminium CNC machining cov qauv

Precision machined steel daim qauv

Stainless hlau ntawv tsab prototypes

Lub siab hardness, melting siab kub cov ntsiab lus cov yam ntxwv thiab siab qhov yuav tsum tau ntawm cov ntaub ntawv hlau txiav txim siab lawv cov cuab yeej technology sib txawv los ntawm cov khoom siv tsis yog xim hlau (xws li plastics) hauv kev ua cov qauv ua qauv lossis cov qauv. Peb lub tuam txhab muab cov qhua tuaj noj mov tag nrho ntawm ib-ncua kev tiv thaiv los yog thuam kev tsim khoom thiab kev pabcuam, suav nrog cov khoom siv yas, cov khoom siv silica gel, cov khoom siv hlau thiab lwm yam. Yog tias koj xav tau, thov hu rau peb.