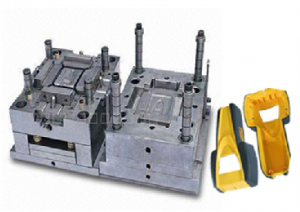

Pob tshab yas moulding

Cov lus piav qhia luv luv:

Cov pob tshab yas khoom siv tau dav siv hauv chaw tsim khoom thiab tib neeg lub neej tam sim no. Pob tshab yas txhaj tshuaj molding ua lub luag haujlwm tseem ceeb hauv kev tsim cov yas.

Vim tias qhov zoo ntawm lub teeb yuag, zoo toughness, yooj yim molding thiab tus nqi qis, plastics yog nce siv los hloov cov iav hauv kev lag luam niaj hnub thiab cov khoom lag luam niaj hnub, tshwj xeeb tshaj yog nyob rau hauv cov twj paj nruag optical thiab ntim kev lag luam. Tab sis vim tias cov ntu pob tshab no yuav tsum muaj pob tshab zoo, siab hnav tsis kam thiab muaj qhov cuam tshuam zoo tawv, kev ua haujlwm ntau yuav tsum tau ua ntawm cov khoom ntawm cov yas thiab cov txheej txheem, cov khoom siv thiab cov pwm ntawm tag nrho cov txheej txheem txhaj tshuaj kom paub meej tias cov yas siv los hloov cov iav. (txuas ntxiv mus rau hu ua cov pob tshab pob tshab) muaj qhov tsis zoo saum npoo av, thiaj li ua tau raws li cov cai ntawm kev siv.

Kuv --- Qhia Taw Qhia Kev Hloov Plaws Plaws Hauv Cov Neeg Txuas Siv

Tam sim no, cov pob tshab pob tshab uas feem ntau siv hauv khw yog polymethyl methacrylate (PMMA), polycarbonate (PC), polyethylene terephthalate (PET), polyethylene terephthalate-1,4-cyclohexanedimethyl glycol ester (PCTG), Tritan Copolyester (Tritan), pob tshab nylon , acrylonitrile-styrene copolymer (AS), polysulfone (PSF), thiab lwm yam Ntawm lawv, PMMA, PC thiab PET yog cov feem ntau siv cov plastics hauv kev txhaj tshuaj molding.

Pob tshab yas yas

2.PC (Polycarbonate)

Cuab yeej:

(1). Tsis muaj kob thiab pob tshab, kis tau ntawm 88% - 90%. Nws muaj lub zog muaj zog thiab elastic coefficient, muaj kev cuam tshuam siab zog thiab dav siv ntau yam kub.

(2). Siab pob tshab thiab dawb dyeing;

(3). Kev ua lub ntsej muag shrinkage yog tsawg ((0.5% -0.6%) thiab ruaj khov qhov ntev yog qhov zoo. Qhov ntom 1.18-1.22g / cm ^ 3.

(4). Cov nplaim hluav taws zoo thiab nplaim retardancy UL94 V-2. Cov cua sov deformation kub yog li 120-130 ° C.

(5). Cov yam ntxwv ntawm hluav taws xob zoo, kev ua tau zoo rwb thaiv tsev (av noo, siab kub kuj tseem tuaj yeem tswj hluav taws xob, yog cov khoom zoo rau kev tsim hluav taws xob thiab hluav taws xob);

(6) HDTis siab;

(7). Zoo weatherability;

(8). PC tsis muaj ntxhiab thiab tsis muaj mob rau tib neeg lub cev thiab yoog nrog kev nyab xeeb huv.

Daim ntawv thov:

(1). Kho qhov muag teeb pom kev zoo: siv rau kev tsim cov teeb ci loj, tiv thaiv iav, sab laug thiab sab xis qhov muag ntsia thawv ntawm cov khoom siv kho qhov muag, thiab lwm yam. Nws tseem tuaj yeem siv dav rau cov ntaub ntawv pob tshab ntawm cov dav hlau.

(2). Cov khoom siv hluav taws xob thiab khoom siv hluav taws xob: Polycarbonate yog cov khoom siv hluav taws xob zoo rau kev tsim cov kab hluav taws xob sib txuas, cov kav hlau, cov yeeb nkab tuav, insulating bushings, plhaub xov tooj thiab qhov chaw, roj teeb lub plhaub ntawm cov ntxhia roj, thiab lwm yam Nws kuj tseem siv tau los ua qhov chaw nrog qhov siab qhov loj. , xws li kev cog lus discs, xov tooj, khoos phis tawm, cov kaw vis dis aus, kev sib tham hauv xov tooj, cov teeb liab txuas mus thiab lwm yam khoom siv sib txuas lus. Polycarbonate nyias kov kuj siv dav ua capacitor. Cov zaj duab xis PC yog siv rau lub hnab insulating, tapes, yeeb yaj kiab xim, thiab lwm yam.

(3). Kev siv tshuab thiab khoom siv: Nws yog siv los tsim ntau yam iav, kab, viav vias, cov kabmob, cams, ntsia hlau, qiv, crankshafts, ratchets thiab lwm yam ntawm cov tshuab thiab khoom siv, xws li plhaub, npog thiab thav ntawv.

(4). Cov cuab yeej siv kho mob: khob, lub tog raj kheej, lub raj mis, tshuaj txhuam hniav, cov tshuaj kho mob thiab cov cuab yeej phais mob uas tuaj yeem siv rau kev kho mob, thiab txawm tias lub raum cuav, lub ntsws thiab lwm yam khoom cuav.

3.PET (Polyethylene terephthalate)

Cuab yeej:

(1). PET cob yog opalescent translucent lossis tsis muaj kob pob tshab, nrog tus txheeb ze ntom ntom ntawm 1.38g / cm ^ 3 thiab transmittance 90%.

(2). PET plastics muaj cov khoom zoo kho qhov muag, thiab amorphous PET plastics muaj qhov zoo optical pom.

(3) .Tus tensile lub zog ntawm PET yog siab heev, uas yog peb zaug ntawm PC. Nws muaj qhov ua kom nruj tshaj plaws nyob rau hauv cov thermoplastic plastics vim tias nws qhov kev ua tau zoo rau U-hloov, nkees thiab kev sib txhuam, hnav qis thiab siab hardness. Nws yog tsim los ua cov khoom nyias-walled xws li cov hwj yas thiab cov zaj duab xis thiab cov yas yeeb yaj kiab.

(4). Kub deformation kub 70 ° C. Nplaim retardant yog qis dua rau PC

(5). Cov tsiaj hwj yog cov muaj zog, pob tshab, tsis muaj tshuaj lom, tsis muaj peev xwm thiab lub teeb rau hauv qhov hnyav.

(6). Weatherability zoo thiab tuaj yeem siv sab nraum zoov siv sijhawm ntev.

(7). Kev ntsuas hluav taws xob ua tau zoo, thiab nws tsis muaj feem cuam tshuam los ntawm qhov kub.

Daim ntawv thov:

(1). Daim ntawv thov ntawm lub raj mis ntim: Nws daim ntawv thov tau tsim los ntawm cov dej haus mus rau lub raj mis npias, roj av tuaj yeem, roj fwj, tshuaj fwj, tshuaj fwj, tshuaj pleev ib ce thiab lwm yam.

(2). Cov khoom siv hluav taws xob thiab khoom siv hluav taws xob: kev sib txuas, cov hlua sib txuas ntawm cov hlau sib txuas, lub plhaw ntawm lub plhaw, lub plhaub sib txuas, lub plhaub hauv plhaw, kev hloov pauv plhaub, TV txuas, lub ntsuas hluav taws xob, cov hloov hluav taws xob, lub plhaw timer, tsis siv neeg fuses, lub cev muaj zog thiab rov xa tawm, thiab lwm yam.

(3). Cov khoom siv tsheb: xws li cov khoom siv faib vaj huam sib luag npog, tiv thaiv kev sib tsoo lub tsho, ntau yam li qub, qhov chaw tso tawm, cov khoom faib tawm, lub ntsuas qhov ntsuas npog, lub cev me me npog, thiab lwm yam, kuj tuaj yeem siv cov txheej txheej zoo tshaj plaws, cov nplaim ntsej muag thiab nruj ntawm PET los tsim cov tsheb sab nraud feem.

(4). Kev siv tshuab thiab khoom siv: kev tsim cov iav, cov cam, cov twj tso kua mis, txoj siv rub, lub cev muaj zog thiab lub moos ntawm qhov chaw, tseem tuaj yeem siv rau microwave cub ci yias, ntau yam ru tsev, sab nraum zoov billboards thiab qauv

(5). TSIAJ yas txoj kev ua cov txheej txheem. Nws tuaj yeem raug txhaj tshuaj, sib txuas, tshuab luam tawm, pleev xim, sib raug zoo, tshuab, kho hluav taws xob, plated plated thiab luam tawm.

PET tuaj yeem ua rau hauv zaj duab xis ntawm qhov tuab ntawm 0.05 hli mus rau 0.12 hli los ntawm kev ncab cov txheej txheem. Zaj duab xis tom qab ncab tas zoo hardness thiab tawv. Transparent PET film yog qhov kev xaiv zoo tshaj plaws ntawm kev tiv thaiv zaj duab xis rau LCD npo. Tib lub sijhawm, PET zaj duab xis kuj tseem yog cov khoom siv ntawm IMD / IMR vim nws cov khoom zoo txhua yam.

Cov ntawv sib piv xaus ntawm PMMA, PC, PET yog cov hauv qab no:

Raws li cov ntaub ntawv hauv Table 1, PC yog qhov kev xaiv zoo rau kev ua tiav, tab sis feem ntau nws yog vim tus nqi siab ntawm cov ntaub ntawv raw khoom thiab qhov nyuaj ntawm kev txhaj tshuaj molding txheej txheem, yog li PMMA tseem yog qhov kev xaiv tseem ceeb. (Rau cov khoom lag luam nrog cov kev xav tau dav dav), thaum PET feem ntau siv rau hauv ntim thiab ntim khoom vim nws yuav tsum ua kom ncav kom tau txais cov khoom zoo.

II --- Cov khoom siv lub cev thiab kev siv cov pob tshab pob tshab siv hauv kev txhaj tshuaj molding:

Cov pob tshab pob tshab yuav tsum xub muaj lub siab pob tshab, thiab qhov thib ob, lawv yuav tsum muaj qee lub zog thiab hnav tsis kam, kev cuam tshuam, kev ua haujlwm zoo thaum tshav kub kub, zoo tshuaj lom neeg tsis kam thiab qhov nqus dej tsawg. Tsuas yog txoj hauv kev no lawv tuaj yeem ua kom tau raws li qhov xav tau ntawm pob tshab thiab nyob twj ywm tsis hloov rau lub sijhawm ntev hauv kev siv. Cov kev ua tau zoo thiab daim ntawv thov ntawm PMMA, PC thiab PET yog piv rau cov hauv qab no.

1. PMMA (Acrylic)

Cuab yeej:

(1). Cov xim tsis muaj pob tshab, pob tshab, pob tshab 90% - 92%, tawv ntau dua li iav iav ntau tshaj 10 zaug.

(2). Optical, insulating, processability thiab weatherability.

(3). Nws muaj lub siab hloov thiab ci ci, zoo thaum tshav kub kub tsis kam, ua kom tawv, txhav, kub deformation kub 80 ° C, dabtsi yog khoov lub zog 110 Mpa.

(4) .Txoj qhov ceev ceev 1.14-1.20g / cm ^ 3, kev hloov pauv tsis xwm yeem 76-116 ° C, ua rau shrinkage 0.2-0.8%.

(5). Linear expansion coefficient yog 0.00005-0.00009 / ° C, qhov kub deformation kub yog 68-69 ° C (74-107 ° C).

(6). Kev daws teeb meem hauv cov organic solvents xws li carbon tetrachloride, benzene, toluene dichloroethane, trichloromethane thiab acetone.

(7). Non-toxic thiab ib puag ncig tus phooj ywg.

Daim ntawv thov:

(1). Cov khoom siv dav siv hauv qhov ntsuas qhov ntsuas, tsheb teeb roj tsheb, lub teeb lo ntsiab muag, cov kav dej pob tshab, txoj kev teeb pom kev zoo.

(2). PMMA resin yog cov khoom siv tsis muaj tshuaj lom thiab ib puag ncig, uas tuaj yeem siv los tsim cov tais diav ntim khoom, ntxuav tais diav, thiab lwm yam.

(3). Nws muaj cov tshuaj lom neeg ruaj khov thiab weatherability. PMMA resin tsis yooj yim los tsim cov khib nyiab ntse thaum tawg. Nws yog siv los ua plexiglass siv silica iav los ua qhov rooj kev nyab xeeb.

PMMA pob tshab yeeb nkab sib koom tes

PMM txiv ntoo txiv ntoo

PMMA pob tshab teeb lub hau

Cov lus 1. Qhov kev sib piv ua tau zoo ntawm cov plooj pob tshab

| Cov cuab yeej | Qhov ceev (g / cm ^ 3) | Tensile zog (Mpa) | Notcimpact zog (j / m ^ 2) | Transmittance (%) | Kub Kev Kub Kub (° C) | Cov ntsiab lus dej tso cai (%) | Ntsws tus nqi (%) | Hnav tsis kam | Tshuaj ua hauj |

| Cov khoom siv | |||||||||

| PMMA | 1.18 | 75 | 1200 | 92 | 95 | 4 | 0.5 | txom nyem | zoo |

| PC | 1.2 .2 | 66 | 1900 | 90 | 137 | 2 | 0.6 | qhov nruab nrab | zoo |

| TSIAJ | 1.37 | 165 | 1030 | 86 | 120 | 3 | 2 | zoo | zoo heev |

Cia peb tsom cov khoom siv PMMA, PC, PET los tham txog cov cuab yeej thiab cov txheej txheem txhaj tshuaj ntawm cov pob tshab pob tshab raws li hauv qab no:

III --- Cov Teeb Meem Yuav Tsum Tau Ceeb Txog Hauv Cov Txheej Txheem Transparent Plastics Pluag Txhaj Tshuaj.

Transparent plastics, vim tias lawv cov transmittance siab, yuav tsum xav kom nruj saum npoo zoo ntawm cov khoom yas.

Lawv yuav tsum tsis muaj qhov tsis xws luag xws li chaw me me, tshuab ntxhua khaub ncaws, nplais ntsej muag, nplaim taws tawg, xim dub, ua kom pom kev thiab tsis zoo. Yog li ntawd, nruj lossis tseem tshwj xeeb yuav tsum tau them sai sai rau hauv kev tsim cov khoom siv raw, khoom siv, pwm thiab txawm tias khoom lag luam thaum lub sijhawm tag nrho cov txheej txheem kev txhaj tshuaj.

Thib ob, vim tias cov pob tshab pob tshab muaj cov nplaim hluav taws xob siab thiab cov npliag tsis zoo, txhawm rau xyuas kom cov khoom zoo ntawm cov khoom, cov txheej txheem cov txheej txheem xws li kub dua, txhaj tshuaj siab thiab txhaj tshuaj nrawm yuav tsum tau kho me ntsis, kom cov plastics tuaj yeem ntim pwm. , thiab kev ntxhov siab sab hauv yuav tsis tshwm sim, uas yuav ua rau deformation thiab tawg ntawm cov khoom.

Cov ntsiab lus hauv qab no yuav tsum tau them sai sai rau hauv kev npaj ntawm raw cov ntaub ntawv, cov tseev kom muaj rau khoom siv thiab pwm, txheej txheem txhaj tshuaj molding thiab cov khoom siv kho mob ntawm cov khoom lag luam.

1 Kev npaj thiab ziab ntawm raw khoom.

Vim tias kev cuam tshuam dab tsi hauv cov plastics yuav cuam tshuam rau lub pob tshab ntawm cov khoom, nws yuav tsum them sai sai rau kev sib khi hauv cov txheej txheem ntawm kev khaws cia, kev thauj mus los thiab kev pub mis kom ntseeg tau tias cov ntaub ntawv raw huv. Tshwj xeeb tshaj yog thaum cov khoom siv raw muaj cov dej, nws yuav qhuav tom qab cua sov, yog li nws yuav tsum qhuav, thiab thaum txhaj tshuaj, qhov kev pub mis yuav tsum siv lub plhaw kom qhuav. Kuj tseem nco ntsoov tias nyob rau hauv cov txheej txheem ziab, cov cua nkag yuav tsum tau lim thiab dehumidified los xyuas kom meej tias cov khoom nyoos tsis tau paug. Cov txheej txheem ziab kom qhuav yog qhia hauv Table 2.

Tsheb PC teeb npog

Pob tshab PC npog rau lub thawv

PC phaj

Rooj 2: Kom qhuav txheej txheem ntawm cov yas pob tshab

| cov ntaub ntawv | ziab qhov kub thiab txias (0C) | sij hawm qhuav (teev) | cov khoom tob (hli) | hais |

| khoom siv | ||||

| PMMA | 70 ~ 80 | 2 ~ 4 | 30 ~ 40 | Huab Cua Cua Txias Cua Txias Kom Qhuav |

| PC | 120 ~ 130 | > 6 | <30 | Huab Cua Cua Txias Cua Txias Kom Qhuav |

| TSIAJ | 140 ~ 180 | 3 ~ 4 | Nruam chav ua kom qhuav |

2. Kev ntxuav ntawm cov kav dej, cov ntsia hlau thiab cov khoom ntxiv

Txhawm rau tiv thaiv kom tsis txhob muaj kuab paug ntawm cov khoom nyoos thiab muaj cov khoom qub lossis tsis zoo nyob rau hauv cov pits ntawm cov ntsia hlau thiab cov khoom ntxiv, tshwj xeeb tshaj yog cov roj av nrog cov thermal tsis zoo, cov ntsia hlau tu tus neeg sawv cev yog siv los ntxuav qhov chaw ua ntej thiab tom qab kaw, yog li ntawd cuam tshuam tsis tuaj yeem tawv ncauj rau lawv. Thaum tsis muaj cov ntsia hlau los tu tus neeg saib xyuas, PE, PS thiab lwm cov resins tuaj yeem siv los ntxuav cov ntsia hlau. Thaum qhov kev kaw ib ntus tshwm sim, txhawm rau tiv thaiv cov khoom kom tsis txhob nyob hauv qhov kub ntawm lub sijhawm ntev thiab ua rau muaj kev puas tsuaj, lub tshuab ziab khaub ncaws thiab lub thoob qhov kub yuav tsum raug txo qis, xws li PC, PMMA thiab lwm qhov cub qhov kub yuav tsum raug txo kom qis dua 160 C. hopper kub yuav tsum qis dua 100 C rau PC)

3. Cov teeb meem xav tau kev tsim tshwj xeeb hauv kev tsim qauv tuag (suav nrog cov qauv tsim khoom) Txhawm rau tiv thaiv cov thim rov qab los sis cov cua txias tsis zoo uas ua rau cov yas tsis zoo, cov teeb meem saum npoo thiab tsis zoo, cov ntsiab lus hauv qab no yuav tsum tau them rau thaum tsim pwm.

A). Cov phab ntsa tuab yuav tsum zoo ib yam li tsim nyog thiab qhov nqes hav qhov rooj yuav tsum loj txaus;

B). Txoj kev hloov yuav tsum yog qeeb me ntsis. Txoj kev hloov pauv kom tiv thaiv cov ces kaum ntse ntse. Yuav tsum tsis muaj qhov sib txawv hauv cov npoo ntse, tshwj xeeb hauv cov khoom PC.

C). rooj vag. Tus khiav yuav tsum dav thiab luv li sai tau, thiab lub rooj vag txoj haujlwm yuav tsum tau teeb tsa raws li cov txheej txheem shrinkage thiab hws, thiab cov tub yees zoo yuav tsum siv thaum tsim nyog.

D). Cov nplaim ntawm qhov tuag yuav tsum du thiab tsis muaj kev ntxhib ntxoo (zoo dua li tsawg dua 0.8);

E). Tso qhov. Lub tank yuav tsum tsim nyog kom tso cua thiab roj cua tawm ntawm cov yaj hauv lub sijhawm.

F). Tsuas yog rau cov PET, cov phab ntsa tuab yuav tsum tsis txhob ua kom nruj dhau, feem ntau tsis tsawg tshaj li l mm.

4. Cov teeb meem xav tau kev saib xyuas hauv kev txhaj tshuaj molding cov txheej txheem (suav nrog qhov yuav tsum tau txhaj tshuaj moulding machine) Txhawm rau txo qhov kev ntxhov siab sab hauv thiab thaj chaw tsis zoo, yuav tsum tau them rau cov hauv qab no hauv kev txhaj tshuaj molding txheej txheem.

A). Cov ntsia hlau tshwj xeeb thiab txhaj tshuaj moulding tshuab nrog cais kub tswj nozzle yuav tsum tau xaiv.

B). Kev txhaj tshuaj ntau dua ntawm cov av noo yuav tsum tau siv ntawm kev txhaj tshuaj kub uas tsis tuaj yeem ua rau cov yas cob.

C). Kev txhaj tshuaj siab: feem ntau siab dua kom kov yeej qhov tsis xws luag ntawm viscosity siab, tab sis lub siab dhau los yuav ua rau muaj kev ntxhov siab sab hauv, uas yuav ua rau lub zog tawg thiab deformation;

D). Kev txhaj tshuaj nrawm: Nyob rau hauv cov ntaub ntawv ntawm kev txaus siab sau, feem ntau nws tsim nyog kom muaj qis, thiab nws yog qhov zoo tshaj rau kev siv cov kev txhaj tshuaj qeeb-qeeb-qeeb ntawm ntau theem;

E). Siab tuav lub sijhawm thiab lub sijhawm sib sau: nyob rau hauv cov ntaub ntawv ntawm kev txaus siab cov khoom lag luam yam tsis tsim kev nyuaj siab thiab kev ua npuas, nws yuav tsum luv li sai tau los txo lub sijhawm nyob ntawm yaj ntawm lub thoob;

F). Cov ntsia hlau ceev thiab nrawm nraub qaum: nyob rau qhov txog ntawm kev txaus siab rau cov khoom siv hauv cov yas, nws yuav tsum muaj qhov qis kom tsawg dua rau kev tiv thaiv kom tsis txhob poob siab;

G). Pwm kub: qhov txias ntawm cov khoom muaj qhov cuam tshuam rau qhov zoo, yog li cov pwm kub yuav tsum muaj peev xwm tswj nws cov txheej txheem kom raug, yog tias ua tau, cov pwm kub yuav tsum muaj ntau dua.

5. Lwm yam

Txhawm rau tiv thaiv kom tsis txhob muaj qhov tsis zoo ntawm cov khoom zoo saum npoo av, tus neeg tso tawm yuav tsum siv tsawg li sai tau hauv kev txhaj tshuaj dav dav, thiab cov khoom siv rov qab yuav tsum tsis pub ntau tshaj 20%.

Rau tag nrho cov khoom tshwj tsis yog PET, kev ua haujlwm tom qab yuav tsum tau ua kom tshem tawm kev ntxhov siab sab hauv, PMMA yuav tsum tau qhuav hauv 70-80 ° C lub voj voog cua kub rau 4 teev, PC yuav tsum tau kho ntawm 110-135 ° C hauv huab cua huv, glycerin , ua kua paraffin, thiab lwm yam. Lub sijhawm ua raws li cov khoom lag luam, thiab qhov xav tau ntau tshaj yog 10 teev. Tsiaj yuav tsum tau hla lub biaxial ncab kom tau cov cuab yeej zoo.

COV TSIAJ hlab

TSIAJ lub raj mis

Tus tsiaj lub rooj

IV --- Txhaj Tshuaj Yas Pwm Tshuab ntawm pob tshab plastics

Cov yam ntxwv thev naus laus zis ntawm plooj pob tshab: Dhau ntawm cov teeb meem saum toj no, pob tshab pob tshab kuj tseem muaj qee cov txheej txheem thev naus laus zis, uas yog cov ntsiab lus raws li hauv qab no:

1. Cov txheej txheem cov txheej txheem ntawm PMMA PMMA muaj viscosity siab thiab tsis muaj fluidity, yog li nws yuav tsum tau txhaj nrog cov khoom kub thiab qhov siab txhaj tshuaj. Kev cuam tshuam ntawm kev txhaj tshuaj kub yog ntau dua li qhov kev txhaj tshuaj siab, tab sis qhov nce ntawm kev txhaj tshuaj yog qhov muaj txiaj ntsig zoo los txhim kho kev txo lub zog ntawm cov khoom. Kev txhaj tshuaj kub yog qhov dav, qhov sov siab yog 160 ° C thiab qhov kub tsis zoo yog 270 ° C yog li cov khoom kub cov kev cai ntsuas tau dav thiab cov txheej txheem ua tau zoo. Yog li, txhawm rau txhawm rau txhawm rau txhawm rau, peb tuaj yeem pib nrog txhaj tshuaj kub. Kev cuam tshuam tsis zoo, qhov tsis zoo hnav tsis kam, yooj yim khawb, yooj yim tawg, yog li peb yuav tsum txhim kho lub ntsuas kub ntawm qhov tuag, txhim kho cov txheej txheem hws, kom kov yeej cov tsis xws luag.

2. Cov txheej txheem cov txheej txheem ntawm PC PC muaj viscosity siab, siab txias thiab tsis muaj fluidity, yog li nws yuav tsum tau txhaj rau qhov kub tshaj (ntawm 270 txog 320T). Muab piv rau hais, qhov ntau ntawm cov khoom siv kho qhov kub thiab txias yog qhov nqaim, thiab qhov txheej txheem tsis zoo xws li PMMA. Kev txhaj tshuaj siab muaj cov nyhuv me me ntawm qhov tsis haum, tab sis vim tias lub siab khov, nws tseem xav tau kev txhaj tshuaj loj dua. Txhawm rau tiv thaiv kev ntxhov siab sab hauv, lub sijhawm tuav yuav tsum luv li sai tau. Tus shrinkage tus nqi yog loj thiab qhov loj me kuj ruaj khov, tab sis sab hauv kev nyuaj siab ntawm cov khoom yog loj thiab nws yooj yim tawg. Yog li, nws raug nquahu kom txhim kho fluidity los ntawm nce qhov kub ntau dua li qhov ua kom lub siab, thiab kom txo qhov muaj peev xwm tawg los ntawm kev nce qhov kub ntawm qhov tuag, txhim kho cov qauv ntawm qhov tuag thiab tom qab kho. Thaum qhov kev txhaj tshuaj nrawm tsawg tsawg, lub rooj vag yog qhov cuam tshuam rau corrugation thiab lwm qhov cuam tshuam, qhov hluav taws xob nozzle kub yuav tsum tswj hwm nyias, cov pwm kub yuav tsum muaj qhov siab, thiab qhov tsis kam ntawm qhov khiav thiab lub rooj vag yuav tsum me me.

3. Cov txheej txheem thev naus laus zis ntawm PET PET muaj qhov sib sau ua qhov kub thiab qhov nqaim ntawm cov khoom kub hloov kho, tab sis nws muaj cov npliag zoo tom qab melting, yog li nws muaj qhov ua haujlwm tsis zoo, thiab cov cuab yeej los tiv thaiv lub zog ntev feem ntau ntxiv hauv lub nozzle. Lub tshuab muaj zog thiab kev ua tau zoo tom qab kev txhaj tshuaj tsis loj, yuav tsum dhau los ntawm txheej txheem kev ncab thiab kev hloov kho tuaj yeem txhim kho kev ua haujlwm. Qhov tseeb tswj kev kub tuag yog los tiv thaiv kev ua tsov ua rog.

Vim tias qhov tseem ceeb tshaj plaws ntawm deformation, kub khiav cov neeg tuag tau raug pom zoo. Yog tias qhov ntsuas kub ntawm qhov tuag tuag siab, cov npoo npoo yuav tsis zoo thiab lub pob zeb tawg yuav tsis yooj yim.

Kem 3. Txhaj Tshuaj Molding Txheej Txheem

| parameter khoom | siab (MPa) | ntsia hlau ceev | ||

| kev txhaj tshuaj | ceev | rov qab siab | (RPM) | |

| PMMA | 70 ~ 150 | 40 ~ 60 | 14,5 ~ 40 | 20 ~ 40 |

| PC | 80 ~ 150 | 40 ~ 70 | 6 ~ 14.7 | 20 ~ 60 |

| TSIAJ | 86 ~ 120 | 30 ~ 50 | 4.85 | 20 ~ 70 |

| parameter khoom | siab (MPa) | ntsia hlau ceev | ||

| kev txhaj tshuaj | ceev | rov qab siab | (RPM) | |

| PMMA | 70 ~ 150 | 40 ~ 60 | 14,5 ~ 40 | 20 ~ 40 |

| PC | 80 ~ 150 | 40 ~ 70 | 6 ~ 14.7 | 20 ~ 60 |

| TSIAJ | 86 ~ 120 | 30 ~ 50 | 4.85 | 20 ~ 70 |

V --- Cov Khoom Siv Tsis Txaus ntawm Cov Khoom Siv Yas Pob tshab

Ntawm no peb tsuas yog tham txog qhov tsis xws luag uas cuam tshuam rau lub pob tshab ntawm cov khoom. Muaj tej zaum cov tsis xws li hauv qab no:

Kev tsis ncaj ncees ntawm cov khoom lag luam pob tshab thiab cov hau kev kom kov yeej lawv:

1 Kev ua kom tawg: qhov tsis zoo ntawm kev ntxhov siab sab hauv lub sijhawm sau thiab hws, thiab cov kev ntxhov siab tsim nyob rau hauv cov kev taw qhia ntsug, ua rau cov cob qhia ntws tawm mus rau sab nraud, thaum cov kev taw qhia tsis ntws tsim flash filament nrog sib txawv refractive index. Thaum nws nthuav tawm, kab nrib pleb kuj yuav tshwm sim hauv cov khoom.

Cov hau kev dhau los: kev ntxuav lub pwm thiab lub thoob ntawm lub tshuab txhaj tshuaj, kom qhuav cov khoom siv txaus, nce cov roj tso pa tawm, nce kev txhaj tshuaj thiab qhov siab nrawm dua, thiab annealing cov khoom lag luam zoo tshaj plaws. Yog tias cov khoom siv PC tuaj yeem ua kom sov siab txog li 160 ° C rau 3 - 5 feeb, tom qab ntawd nws tuaj yeem txias kom zoo.

2. Npuas: Cov dej thiab lwm cov roj hauv cov dej tsis tuaj yeem tawm (thaum lub sijhawm ua cov pwm hws) lossis "nqus npuas" yog tsim vim qhov ua tsis txaus ntawm pwm thiab ua kom dhau hws sai ntawm cov hws. Cov hau kev dhau ntawm suav nrog kev ua kom muaj zog thiab ua kom qhuav txaus, ntxiv cov rooj vag ntawm phab ntsa rov tom qab, nce siab thiab nrawm, txo qhov kub siab thiab ua kom ntev dua lub sijhawm txias.

3. Lub ntsej muag tsis zoo rau lub ntsej muag: feem ntau vim yog qhov loj ntawm lub cev tuag, ntawm qhov tod tes, dhau hws ua ntej, yog li cov roj nplaum tsis tuaj yeem luam lub xeev ntawm qhov tuag saum npoo, tag nrho cov uas ua rau saum npoo ntawm tuag me ntsis tsis sib xws. , thiab ua kom cov khoom lag luam ploj ntuag. Cov txheej txheem los kov yeej cov teeb meem no yog kom kub kub melting, pwm kub, txhaj tshuaj siab thiab txhaj tshuaj nrawm, thiab lub sijhawm ua kom txias txias.

4. Seismic ripple: ntom ntwm ripple tsim los ntawm nruab nrab ntawm lub rooj vag ncaj. Qhov laj thawj yog tias cov viscosity yaj yog siab dhau, cov khoom siv rau pem hauv ntej tau ntim rau hauv cov kab noj hniav, thiab tom qab ntawd cov khoom tawg ntawm cov hws ua kom nto, uas ua rau saum npoo. Cov hau kev dhau los yog: nce kev txhaj tshuaj siab, lub sijhawm txhaj tshuaj, lub sijhawm txhaj tshuaj thiab qhov nrawm dua, nce pwm nce, xaiv lub pob hluav taws xob tsis tsim nyog thiab ua kom txias rau lub qhov dej.

5. Ntsig. Kev pos huab: Nws yog los ntawm hmoov av poob mus rau cov khoom siv hauv huab cua lossis huab cua ntau dhau ntawm cov khoom siv raw. Cov kev kov yeej yog: tshem cov impurities ntawm kev txhaj tshuaj moulding tshuab, kom ntseeg tau txaus dryness ntawm yas raw cov ntaub ntawv, raug tswj melting kub, nce pwm kub, nce rov qab lub siab ntawm kev txhaj tshuaj molding thiab luv lub voj kev txhaj tshuaj. 6. Cov pa luam yeeb dawb. Cov Khoom Dub: Nws feem ntau yog ua los ntawm kev xaim lossis kev puas tsuaj ntawm cov roj ntoo hauv lub thoob ua rau los ntawm lub zos overheating ntawm cov yas hauv lub thoob. Txoj kev dhau ntawm txoj kev yog txo lub melting kub thiab chaw nyob lub sij hawm ntawm cov ntaub ntawv raw khoom hauv lub thoob, thiab nce lub qhov tso kom zoo dua.

Lub tuam txhab Mestech tshwj xeeb hauv kev muab cov neeg siv khoom kom pom lub teeb pom kev zoo, cov khoom siv kho mob hluav taws xob vaj huam sib luag pwm thiab kev txhaj tshuaj. Yog tias koj xav tau qhov no, thov hu rau peb. Peb zoo siab los muab cov kev pabcuam rau koj.