Cov lus qhia rau cov qauv yas ua cov qauv yas thiab moulding

Cov lus piav qhia luv luv:

Precision yas ntu tsim thiab txhaj tshuaj molding yuav tsum pib hauv cov khoom siv, cov qauv tsim qauv, tsim pwm thiab kev ua tiav, txhaj tshuaj moulding tshuab, kev ua haujlwm zoo thiab ib puag ncig zoo.

Nrog rau kev txhim kho ntawm kev lag luam niaj hnub no, muaj ntau dua thiab ntau dua cov ntaub ntawv yas. Nyob rau tib lub sijhawm, cov khoom yas kuj tseem siv tau hauv ntau lub lag luam. Tshwj xeeb, ntau dua thiab ntau dua qhov dua ntawm cov yas yog siv. Tam sim no cia peb qhia koj cov lus qhia rau cov ntu yas tsim thiab txhaj tshuaj molding.

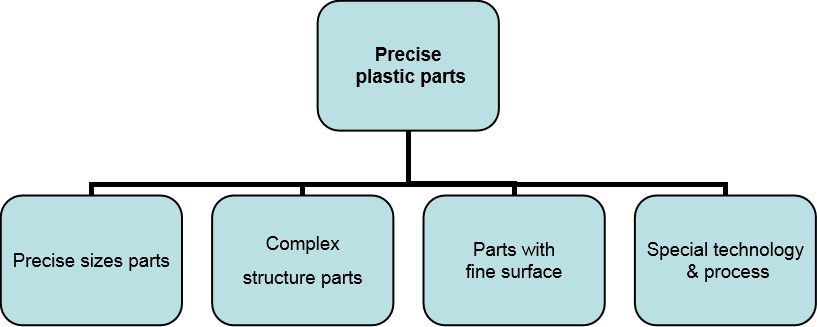

Kev faib tawm ntawm cov neeg

yas qhov chaw:

1. Kev tsim cov qib ntu hauv cov yas

(1) Cov ntaus ua ntu ntawm cov ntu yas ua yog

A. Cov qhov loj ntawm qhov tseeb, xws li: cov npluag ntuag rau lub cev, cov kabmob cab, cov ntsia hlau, cov kabmob. Cov khoom siv npliag no feem ntau siv nyob rau hauv qhov npliag kis ntawm cov tshuab (xws li tshuab luam ntawv, lub koob yees duab, tsis siv neeg lub tshuab nqus tsev, robots, cov cuab yeej ntse, UAV me me, thiab lwm yam). Nws yuav tsum muaj kev sib koom ua ke, du txav, durability thiab suab nrov tsis pub.

B. nyias-walled qhov chaw:

Feem ntau, cov phab ntsa ntawm cov khoom yas yog tsawg dua 1.00 hli, uas yog rau cov ntu-phab ntsa. Nyias-phab ntsa qhov chaw tuaj yeem ua rau qhov loj me ntawm cov khoom me me. Tab sis yas-thin-walled qhov chaw tuaj yeem nyuaj vim tias muaj qhov nrawm txias thiab solidification. Thiab qhov nyias-phab ntsa hauv qhov chaw tsis tuaj yeem tiv thaiv lub zog ntawm tus tuag thiab tawg hauv lub cav kab noj hniav kom tuag. Yog li ntawd, tus qauv tsim ntawm cov phab ntsa-nyias-nyias yuav tsum xaiv cov khoom siv nrog cov cuab yeej zoo dua. Thiab tsim qauv tsim nyog, xws li niaj hnub ua ke phab ntsa tuab, qhov chaw tsis tuaj yeem yog phab ntsa dhau. Kev sib sib zog nqus tuag, lub kaum sab xis loj dua. Rau qee qhov ntu ultra-thin, kev kub siab txhaj tshuaj molding tshuab yog qhov xav tau.

C. Qhov kho qhov muag:

Optical qhov chaw yuav tsum zoo transmittance / lub teeb diffusion kev ua tau zoo, nrog rau kev ua kom zoo seem ruaj khov thiab hnav tsis kam. Piv txwv li, qhov chaw npoo ntawm concave thiab convex lo ntsiab muag siv hauv projectors yuav tsum muaj qhov raug thiab qhov ruaj khov. High yas pob tshab xws li PMMA yog xav tau. Nyob rau tib lub sijhawm, qee qhov teeb pom kev zoo kho qhov muag kuj yuav tsum tau ua qee txoj kab zoo ntawm qhov chaw ntawm qhov yuav tau txais qhov kaj lossis txawm lub teeb lossis tshem tawm lub ntsej muag ci.

D. High-gloss nto:

High-gloss qhov chaw muaj xws li cov khoom siv kho qhov muag, thiab lwm qhov uas xav tau qhov chaw ua tiav siab (daim iav saum npoo av). Qhov seem ntawm no tau siv dav hauv cov khoom siv hluav taws xob, xws li lub plhaw xov tooj ntawm tes. Kev tsim qauv ntawm cov khoom lag luam no yuav tsum xav txog cov ntaub ntawv yas nrog cov fluidity zoo, tsim cov tuab thiab tuag technology.

E. tawv yas seem

Ntau yam khoom siv hluav taws xob thiab hluav taws xob xav tau dej-pov thawj, xws li tsom iav tiv thaiv dej / tsom iav / cov tub rog hluav taws xob, cov khoom siv sab nraum zoov thiab cov twj siv nrog dej noo ib puag ncig. Cov hau kev tseem ceeb ntawm kev siv dej ntawm lub ntsej muag yog encrypted cov ntsaws ruaj ruaj rau sab nraud ntawm cov khoom lag luam, xws li cov khoom siv tuav, ntawm lub tsho sab nraud, sib khi ntawm lub puab, ultrasonic vuam, thiab lwm yam.

F.IMD / IML (hauv-pwm-kho kom zoo nkauj, hauv-pwm-daim ntawv lo)

Tus txheej txheem no yog tso PET zaj duab xis tso rau hauv kev txhaj tshuaj pwm kab noj hniav thiab sib sau cov qhov txhaj tshuaj mus rau hauv kev siv tshuab tag nrho, uas yuav lo ruaj ruaj rau cov ntu yas. IMD / IML cov khoom nta: siab tseeb, stereoscopic, tsis ploj li; pob tshab ntawm cov iav lo ntsiab muag ntau npaum li 92%; hnav-resistant thiab kos-nto nto rau kev pab lub neej ntev; ntab ntim cov khoom tseem ceeb thaum txhaj tshuaj molding, lub neej tseem ceeb tuaj yeem ncav ntau dua 1 lab npaug.

Nyias phab ntsa yas ib feem

IMD / IML vaj huam sib luag yas

Precise qhov chaw yas

Optical qhov / pob tshab npog

Ob chav txhaj dej rooj plaub

Cov ntaub ntawv tshwj xeeb rau cov khoom siv hluav taws xob

Cov vaj tsev zoo nkauj ntawm cov qauv kab zauv

(2) .Txog kev ua rau cov yas ua tau ntu qauv siv

A. Kev ntsuas ntawm phab ntsa tuab Hauv kev txhaj tshuaj molding, yas yog nyob rau hauv lub xeev ua kua rau lub sijhawm luv heev, thiab kev sib thooj ntawm phab ntsa tuab ntawm qhov muaj qhov cuam tshuam zoo rau qhov khiav nrawm thiab kev coj ntawm yas. Lub thickness ntawm qhov hloov pauv ntau heev, uas yuav coj cov teeb meem tsis zoo xws li sau tsis txaus siab, deformation, shrinkage, weld qhab nia, tuab thiab nyias qhov kev nyuaj siab, thiab lwm yam Yog li ntawd, cov phab ntsa tuab ntawm cov nplaim yas qhov chaw yuav tsum zoo tib yam li tau hauv kev tsim. Kev hloov pauv yuav tsum tsis txhob loj dhau, thiab txoj kab nqes hla lossis arc kev hloov yuav tsum tau ua nyob rau hauv kev hloov.

B. them sai sai rau kev sib koom tes ntawm cov ntu thiab ua qhov loj me rau kom ua. Txhawm rau kom ntseeg tau qhov sib hloov ntawm ib feem, peb feem ntau muab cov kev cai nruj rau qhov tseeb ntawm cov ntu ntawm ib leeg. Tab sis rau seem yas, nws muaj qee qhov yooj thiab ywj. Qee zaum, ntev li ntev tau ntawm tus qauv tsim tsim nyog, qhov sib txawv tuaj yeem kho los ntawm kev sib txuam ntawm cov ntu, yog li tus qauv tus qauv yuav tau so kom tsim nyog los txo cov khoom lag luam. Qib.

C. Kev xaiv cov khoom siv Nws muaj ntau yam khoom siv yas, thiab lawv cov kev ua haujlwm nws txawv heev. Txog cov npliag yas, cov ntaub ntawv nrog me me ntsws / tsis kam / zoo qhov ntev / kev nyab xeeb / huab cua zoo kuj raug xaiv raws li qhov yuav tsum tau siv. (a) ABS / PC nrog qis qis qis yog siv los hloov PP nrog lub siab ntsws, thiab PVC / HDPE / LDPE nrog tsawg shrinkage. ABS + GF yog siv los hloov ABS.PC + GF nrog PC. (b) Xaiv PA66 + GF lossis PA6 + GF hloov POM lossis PA66 thiab PA6.

D. siab xav txog cov txheej txheem molding.

(a) Rau lub ntsej muag tuab plhaub, lub thawv lossis qhov chaw txiav tawm, nws zoo dua rau kev tsim microstrip arc rau saum npoo thiab txhawb nqa rau sab hauv kom tsis txhob deformation.

(b) Rau ultra-nyias feem, tuab ntawm seem yuav tsum zoo ib yam, thiab sab hauv yuav tsum tsis txhob sib sib zog nqus txhawb nqa cov tav lossis txoj hauv kev. Nws raug nquahu kom siv kev txhaj tshuaj ntau dua nrawm molding tshuab.

(c) Cov kub khiav tawm los yog kub khiav tawm pwm yog siv rau qhov loj kom ntev lub sijhawm sau thiab txo kev ua kom muaj kev ntxhov siab thiab deformation.

(d) rau ob feem tivthaiv ua los ntawm ob cov ntaub ntawv, ob chav xim txhaj hloov chaw txhaj tshuaj kua nplaum yog saws.

(e) txhaj tshuaj ntsug yog pom zoo rau cov ntu nrog cov ntawv hlau me.

E. Muaj chav rau kev ua kom zoo dua. Hauv kev tsim qauv ntawm cov yas ncaj qha, nws yog qhov yuav tsum tau los soj ntsuam kev hloov tau hauv kev tsim khoom yav tom ntej.

(3) Tsim pov thawj

Kev txhaj tshuaj pwm muaj tus nqi siab, lub sijhawm ntev thiab tus nqi siab ntawm kev hloov kho, yog li tom qab qhov pib ua tiav ntawm ib feem tsim, nws yuav tsum ua cov qauv kuaj lub cev kom paub tseeb qhov tsim, thiaj li txiav txim siab meej meej ntawm cov khoom tsim tsis dhau, nrhiav teeb meem thiab txhim kho ua ntej.

Kev tsim qauv ntawm daim ntawv pov thawj lub cev yog qhov ua tiav yog los ntawm kev ua tus qauv ntawm tus qauv. Muaj ob yam qauv tiv thaiv: CNC ua thiab 3D luam ntawv.

Kev siv ntawm kev ntsuas lub cev ua pov thawj xav tau kev saib xyuas rau cov hauv qab no:

A.CNC cov qauv tsim tawm cov nqi feem ntau siab dua li 3D luam ntawv. Rau seem loj, tus nqi ntawm kev ua haujlwm CNC yog tus nqi tsawg.

Rau cov khoom siv thiab cov khoom siv kho tshuab lossis kev kho deg thiab cov khoom sib dhos, CNC ua kom pom zoo, yog li ua kom tau zoo txhua yam muaj zog. Rau qhov loj me me thiab tsis tshua muaj zog qhov chaw, luam ntawv 3-D yog siv. 3-D luam ntawv nrawm dua, thiab nws pheej yig dua rau cov khoom me me.

B. Prototypes feem ntau tuaj yeem xyuas qhov sib dhos sib txuam ntawm qhov chaw, kuaj xyuas cov qauv yuam kev thiab tsis ua haujlwm, thiab pab txhawb kev tsim qauv. Txawm li cas los xij, qhov qauv tsis tuaj yeem feem ntau xav txog qhov thev naus laus zis kev xav tau ntawm cov pwm tsim, xws li moulding lub kaum sab xis / lub ntsej muag / lub cev deformation / kev sib txuas thiab lwm yam

2. npliag yas seem hauv moulding

(1) yas txhaj tshuaj pwm tsim (pwm tsim) Cov pwm yas muaj txiaj ntsig zoo yog tus yuam sij rau kev ua qhov chaw npliag. Cov ntsiab lus hauv qab no yuav tsum tau ua raws.

A. raug xaiv qhov shrinkage coefficient ntawm cov khoom yas. Qhov chaw tsim nyog ntawm cov ntu ntawm cov pwm.

B. pwm tub ntxhais cov khoom yuav tsum xaiv cov khoom siv steel nrog kev zoo / hnav tsis kam / ua hauj corrosion.

C. pwm kev siv tshuab siv kub Tsui lossis kub khiav kom deb li deb tau, kom cov ntu ntawm txhua ntu ntawm qhov kub tsis sib thooj, txo kev deformation.

D. pwm yuav tsum muaj lub tshuab cua txias zoo kom paub meej tias qee qhov chaw txias txias tusyees hauv lub sijhawm luv.

E. pwm yuav tsum muaj sab xauv thiab lwm qhov chaw muab tso ua ke.

F. tsim nyog qhov teeb meem chaw ntawm ejector mechanism, kom lub zog ejection ntawm qhov chaw yog qhov tsis zoo thiab tsis deformed.

Mould tsim thiab txheeb xyuas cov cuab yeej tseem ceeb (pwm ua haujlwm): Siv cov kev sim software ntawm kev txhaj tshuaj molding los qog cov nyhuv ntawm cov txheej txheem txhaj tshuaj pwm nyob rau hauv cov teeb tsa sib txawv, nrhiav qhov tsis xws ntawm cov khoom tsim thiab pwm tsim ua ntej, txhim kho thiab ua kom zoo, thiab zam qhov yuam kev loj hauv kev tsim pwm rau qhov loj tshaj plaws, uas tuaj yeem ua kom ntseeg tau qhov zoo ntawm pwm thiab txo tus nqi tom qab.

(2) txheeb xyuas pwm.

Tus nqi ntawm cov pwm yooj yim yog qis dua qhov ntau ntawm pwm. Txog kev txhaj tshuaj ua ntu yas, nws yog ib qho tsim nyog ua kom yooj yim pwm kom paub tseeb qhov qauv ntawm cov pwm ua ntej ua cov pwm ua cov pwm, kom thiaj li tau txais cov kev tsim los txhim kho cov qauv tsim pwm thiab kom ua tiav cov pwm ua tiav.

(3) pwm ua tiav

Cov pwm yas siab yuav tsum tau muab cov tshuab nrog cov tshuab loj hauv qab no.

A. high precision tshuab CNC tshuab cuab tam

B. daim iav siv lub tshuab ci ntsa iab

C. maj mam xaim txiav

D. ib puag ncig kub ua hauj lwm ib puag ncig

E. cov khoom tsim nyog soj ntsuam. Ntxiv rau, kev lag luam pwm yuav tsum ua raws li cov txheej txheem nruj thiab cia siab rau cov neeg ua haujlwm zoo los ua haujlwm.

(4) txhaj tshuaj molding tshuab xaiv

Cov cuab yeej siv rau kev txhaj tshuaj molding ntawm qib siab meej yas ntu.

A. yuav tsum tau siv lub tshuab txhaj tshuaj kom meej thiab tsis pub dhau 5 xyoos kev pab lub neej.

B. ib puag ncig Hoobkas yog huv thiab huv si.

C. rau feem ntau thau-tawm-seem, yuav tsum muaj lub tshuab ua kom zoo siab txhaj tshuaj.

D. ob chav xim lossis ntu ntu dej yuav tsum muaj ob lub tshuab txhaj tshuaj xim.

F. lub suab zoo tswj lub zog

(5) ntim rau cov ntu yas

Kev ntim khoom zoo yog qhov tseem ceeb los tiv thaiv qhov khawb, deformations, plua plav hauv tsheb thauj mus los, khaws cia ntawm cov yas ua tau zoo.

A. siab gloss qhov yuav tsum tau muab xaim nrog zaj duab xis tiv thaiv.

B. cov phab ntsa nyias nyias yuav tsum tau qhwv hauv cov hnab ris tshwj xeeb los yog ua npuas, lossis sib cais los ntawm rab riam ntawv kom tsis txhob raug lub siab.

C. Cov khoom uas xav thauj mus los ntawm qhov chaw deb ntev yuav tsum tsis txhob muab tso xoob hauv cov thawv. Ntau lub thawv yuav tsum muab sib dhos ua ke los ntawm cov tuav taw thiab tus tiv thaiv.

Lub tuam txhab Mestech muaj cov tshuab thiab khoom siv rau kev ua cov yas pwm yas txhaj tshuaj thiab txhaj tshuaj molding kev lag luam. Peb vam tias yuav muab koj cov pwm ua thiab cov kev pab cuam ntau lawm rau cov khoom seem yas.