PC cob txhaj molding

Cov lus piav qhia luv luv:

PC cob (polycarbonate) txhaj tshuaj txhaj tshuaj yog qhov dav siv hauv cov khoom hluav taws xob, cov khoom siv hluav taws xob cov plhaub thiab cov khoom siv hluav taws xob.

PC resin txhaj tshuaj molding qhov yog dav siv hauv cov khoom hluav taws xob, khoom siv hluav taws xob plhaub thiab cov khoom siv hluav taws xob.

Dab tsi yog PC cob?

Dab tsi yog PC cob (polycarbonate) feem ntau paub tias yog polycarbonate, vim tias nws cov cuab yeej zoo heev, feem ntau hu ua cov kua nplaum-pov thawj kua nplaum. PC muaj cov yam ntxwv ntawm siab muaj zog tshuab, dav kub ntau yam, zoo hluav taws xob rwb thaiv tsev ua tau zoo (tab sis arc tsis hloov), zoo rau sab hauv qhov ruaj khov thiab pob tshab.

Cov xim qub ntawm PC tsis muaj xim thiab pob tshab. Ntau cov pob tshab, cov pom kev thiab cov xim tsis muaj tseeb thiab lub teeb tsis sib xws muaj peev xwm muab tau los ntawm kev ntxiv toner lossis master pob. Qhov no ua kom yooj yim los ua lub teeb duab ntxoov ntxoo thiab lwm qhov chaw nrog ntau yam xim.PC kuj muaj ntau yam khoom siv hloov kho, xws li iav fiber, cov ntxhia ua kom zoo nkauj, tshuaj nplaim hluav taws thiab lwm yam plastics.

PC muaj lub cev tsis zoo thiab kev ua haujlwm kub, yog li kev ua tiav ntawm ntau qib ntawm cov ntaub ntawv hloov kho yuav tsum tau tshwj xeeb yas txheej txheem kev txhaj tshuaj.

Ntau yam xim tom qab ntxiv toner lossis masterbatch

Thawj xim ntawm PC cob

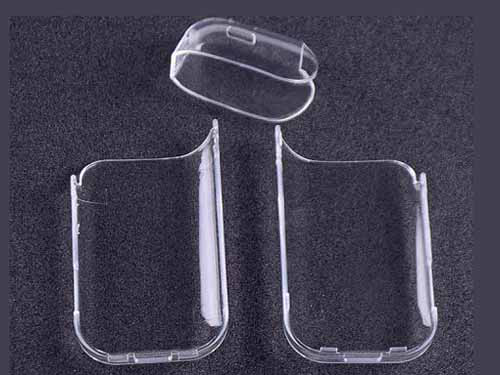

Lub cev tsis dhau ntawm PC cob

Ntu: 1.18-1.22 g / cm ^ 3 kab kev nthuav dav: 3.8 * 10 ^ -5 cm / C thermal deformation kub: 135 C tsis kub - 45 CPC (Polycarbonate) tsis muaj xim, pob tshab, kub-resistant, cuam tshuam-resistant, nplaim taws-kawm qib BI qib, thiab muaj cov yam ntxwv zoo hauv qhov kub thiab txias siv. Piv nrog polymethyl methacrylate, polycarbonate muaj qhov cuam tshuam zoo, siab refractive index thiab kev ua haujlwm zoo. Nws muaj UL94 V-2 nplaim taws qeeb qeeb yam tsis muaj qhov ntxiv. Cov coj tsis kam ntawm polycarbonate tsis zoo. Qee cov polycarbonate khoom siv rau cov kev coj ua tsis yooj yim xav tau kev kho tshwj xeeb saum npoo av.

Dab tsi yog PC resin Siv rau?

Cov khoom siv hauv PC muaj qhov kub tsis kam ua haujlwm, siab zog, zoo toughness, feem cuam tshuam, nplaim taws rov qab, dav siv qhov kub thiab txias, tsis muaj tshuaj lom, pob tshab txog li 90%, thiab cov cuab yeej zoo nyob hauv kev siv kub. High dimension stability, shrinkage tus nqi yog tsawg heev, feem ntau 0.1% ~ 0.2%. Siv dav hauv: cov khoom siv hluav taws xob, cov teeb pom kev zoo, cov khoom siv kho mob, kho qhov rooj, tshuab thiab lwm yam khoom lag luam thiab khoom siv.

Pob tshab txiv hmab txiv ntoo cov paib

Pob tshab PC tiv thaiv npog

Pob tshab & translucent PC teeb duab ntxoov ntxoo

Kev sib txuas ntawm PC cob

PC txhaj tshuaj molding vaj tse

PC teeb npog

Kev txhaj tshuaj molding ntawm PC cob khoom yog dab tsi?

1. Kev kho mob yas

PC muaj dej nqus dej siab dua. Nws yuav tsum tau preheated thiab qhuav ua ntej ua tiav. PC ntshiab yog ziab ntawm 120 C. Hloov Kho PC yog feem ntau qhuav ntawm 110 C rau ntau dua 4 teev. Lub sijhawm ziab yuav tsum tsis pub tshaj 10 teev. Hauv kev siv dav dav, huab cua los tiv thaiv txheej txheem tuaj yeem siv los txiav txim siab seb puas ziab yog txaus.

Qhov feem ntawm cov khoom siv rov ua dua tshiab tuaj yeem ncav cuag 20%. Muaj qee kis, 100% cov khoom siv rov ua dua tshiab tuaj yeem siv, thiab qhov nyhav tiag tiag yog nyob ntawm qhov ua tau zoo ntawm cov khoom. Cov khoom siv rov qab siv tsis tau cov khoom sib txawv ntawm cov xim masterbatches tib lub sijhawm, txwv tsis pub cov khoom ntawm cov khoom tiav yuav raug puas ntsoog.

2. Xaiv qhov Txhaj Tshuaj Molding Tshuab

Vim tias tus nqi thiab lwm yam, PC khoom tam sim no siv cov ntaub ntawv hloov kho dua tshiab, tshwj xeeb tshaj yog cov khoom siv hluav taws xob, tab sis kuj xav tau kom muaj kev tiv thaiv hluav taws. Hauv kev tsim cov nplaim hluavtaws-rov ua dua PC thiab lwm cov khoom siv yas yas, qhov yuav tsum tau ua ntawm cov txheej txheem yas txheej txheej ntawm kev txhaj tshuaj moulding tshuab yog qhov sib xyaw zoo thiab tiv taus corrosion. Pa ya yas ntsia hlau nyuaj yog kev nyuaj. Thaum xaiv thiab yuav khoom, nws yuav tsum muaj tseeb. Nws yuav tsum tau piav qhia ua ntej.

3. Tsim Mould thiab Rooj Vag

Cov pwm kub feem ntau yog 80-100 C, ntxiv rau iav fiber ntau yog 100-130 C, cov khoom lag luam me tuaj yeem siv rab koob rooj vag, lub rooj vag qhov tob yuav tsum yog 70% ntawm cov tuab, lwm lub rooj vag muaj lub nplhaib thiab lub duab plaub.

Lub qhov rooj loj dua, nws yuav zoo dua los txo qhov tsis xws luag tshwm sim los ntawm kev txiav ntau dhau ntawm cov yas. Qhov tob ntawm lub qhov tso pa yuav tsum tsawg dua 0.03-0.06mm, thiab qhov khiav yuav tsum muaj luv thiab puag ncig li sai tau. Txoj kab nqes ntawm demoulding feem ntau yog 30'-1 degree

4. Qhuav ntawm kub

Huab cua txhaj txheej txheem tuaj yeem siv los txiav txim siab ntsuas kev ua haujlwm. Feem ntau, kev ua haujlwm kub ntawm PC yog 270-320 C, thiab qee qhov hloov kho lossis qis molecular phaus PC yog 230-270 C.

5. Kev txhaj tshuaj nrawm

Nws yog ib qho uas siv kev txhaj tshuaj sai ceev kom zoo rau lub cev, xws li hloov mus thiab tua cov cuab yeej hluav taws xob. Feem ntau yog qeeb rau sai prototyping.

6, rov qab siab

Kev nrawm nraub qaum ntawm txog 10 bar tuaj yeem txo kom tsawg tsim nyog thaum tsis muaj qhov chaw tso cua thiab duab liab qab.

7. Lub sijhawm nyob ntawm kev txwv

Yog tias cov khoom ntim nyob rau qhov kub siab rau lub sijhawm dhau mus ntev, nws yuav thim tawm, tso tawm CO2 thiab tig daj. Tsis txhob ntxuav lub thoob nrog LDPE, POM, ABS lossis PA. Siv PS tu

PC resin yog ib qho ntawm plaub qhov feem ntau siv cov ntaub ntawv yas. Mestech tau siv ntev siv PC plastics thiab nws cov alloys rau kev txhaj tshuaj molding los ua ntau yam yas. Peb tau cog lus rau kev pabcuam rau cov neeg siv khoom molding thiab txhaj tshuaj molding ntawm cov khoom zoo no. Yog tias tsim nyog, thov hu rau peb.