Yas txhaj tshuab

Cov lus piav qhia luv luv:

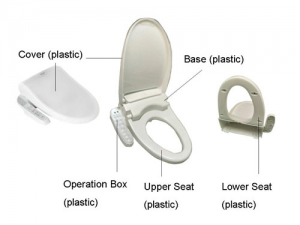

Mestech yog nruab nrog 30 yas txhaj tshuaj molding tshuablos ntawm 100 tons rau 1500 tons thiab 10 cov kev paub txog kev ua haujlwm tshaj lij. Peb tuaj yeem muab txhaj tshuaj molding cov khoom ntawm ntau qhov ntau thiab tsawg rau peb cov neeg siv khoom

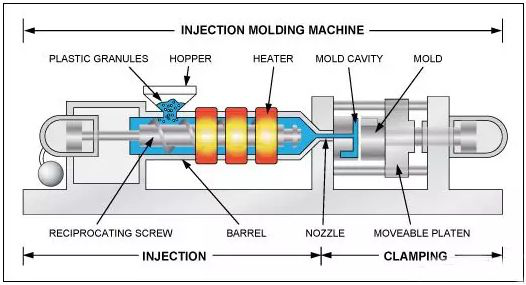

Lub tshuab txhaj tshuaj yas tseem hu ua lub tshuab txhaj tshuaj lossis tshuab txhaj tshuaj. Nws yog cov khoom siv moulding tseem ceeb uas ua rau thermoplastic lossis thermosetting yas rau hauv cov khoom yas ntawm ntau yam duab los ntawm kev siv cov yas txhaj tshuaj pwm. Cov kev khiav dej num ntawm cov yas txhaj tshuaj moulding tshuab yog ua kom kub cov yas, thov kom ua haujlwm siab rau cov tshuab ua hlau, thiab ua rau lawv tua thiab sau pwm kab noj hniav.

I-Kev faib tawm ntawm kev txhaj tshuaj yas tshuab tshuab Kev txhaj tshuaj yas tshuab tshuab muaj peev xwm tsim cov khoom yas nrog cov tsos tsis yooj yim, qhov loj me lossis ntom ntom ntom nrog cov ntawv hlau ntxig tib lub sijhawm. Nws yog dav siv hauv kev tiv thaiv teb chaws, electromechanical, tsheb, tsheb thauj mus los, cov ntaub ntawv hauv tsev, ntim khoom, ua liaj ua teb, kab lis kev cai, kev kawm, noj qab haus huv thiab tib neeg lub neej txhua hnub. Nrog txoj kev loj hlob sai ntawm cov yas kev lag luam thiab cov qauv nyuaj thiab cov haujlwm ntawm cov khoom siv moulding, ntau hom thiab cov ntsiab lus ntawm kev txhaj tshuaj molding tshuab tau tsim raws li. Raws li qhov tseeb ntawm cov khoom tsim tawm, cov tshuab txhaj tshuaj tuaj yeem muab faib ua qhov dog dig thiab raug txhaj tshuaj molding tshuab. Raws li lub zog tswj thiab kev tswj hwm, lub tshuab txhaj tshuaj tuaj yeem muab faib ua hydraulic thiab txhua lub tshuab fais fab txhaj tshuaj. Raws li cov txheej txheem txheej txheem ntawm kev txhaj tshuaj molding tshuab, nws muaj peb yam: ntsug thiab kab rov tav (suav nrog ob xim txhaj tshuaj molding tshuab) thiab hom kaum.

Cov lus qhia rau tus yam ntxwv ntawm ntau yam kev txhaj tshuaj molding tshuab

5. Qhov cuab yeej hloov pwm pwm tseem qhib ib puag ncig, yooj yim los txhim kho txhua yam ntawm cov khoom siv tsis siv neeg, haum rau cov khoom siv ua tau zoo, ua haujlwm ntawm tsis siv neeg molding.

6. cov khoom siv thauj khoom siv tau yooj yim kom paub qhov nruab nrab nruab los ntawm lub pwm, thiaj li ua kom yooj yim cov tsis zoo no feem ntau lawm.

7. Nws yog qhov yooj yim los xyuas kom meej ntawm cov dej ntws ntawm cov dej ntws tawm thiab pwm kub kev faib tawm hauv pwm.

8. Nruab nrog tig lub rooj, txav cov lus thiab lub rooj inclined, nws yog qhov yooj yim rau kev nkag siab tso tawm molding thiab tuag ua ke molding.

9. me me ua pob khoom siv ntau lawm, cov qauv pwm yog yooj yim, tus nqi qis, thiab yooj yim rau kev tshem tawm.

10. lub tshuab ntsug vim tias qhov nruab nrab ntawm qhov nruab nrab ntawm kev sib tsoo, kev sib nqus ntawm kab rov tav kuj zoo dua.

1.Hor rov qab txhaj tshuaj tshuab

1.even yog tias qhov mainframe tsawg tsawg vim nws lub cev qis, tsis muaj qhov siab txwv rau ntawm cov ntoo.

2.Qhov khoom tuaj yeem poob qis, tsis muaj kev siv lub tshuab ntawm tes, tsis siv neeg molding tseem tuaj yeem ua tiav.

3.cim ntawm cov fuselage qis, yooj yim pub mis, txij nkawm yooj yim.

4.mold yuav tsum tau teeb tsa los ntawm crane.

5.multiple parallel arrangement, cov khoom lag luam moulded yog yooj yim los sib sau thiab ntim ntawm cov khoom siv conveyor.

2.Vimical txhaj tshuaj molding tshuab

1. Lub tshuab txhaj tshuaj thiab lub tshuab tuav yog nyob ntawm tib qho chaw nruab nrab, thiab cov tuag yog qhib thiab kaw raws cov lus qhia sab saud thiab qis. Nws thaj chaw hauv av tsuas yog ib nrab ntawm lub tshuab kab rov tav, yog li hloov mus rau thaj chaw ntau lawm ntawm kwv yees li ob zaug ntawm kev tsim khoom.

2. yooj yim kom ua tiav kev txhaj tshuaj molding. Vim tias cov nplaim tuag sab saud, tus ntxig yog yooj yim mus nrhiav chaw. Kev siv lub tshuab tuaj rau moulding tuaj yeem yooj yim pom tau los ntawm kev siv lub tshuab hom nrog tus qauv qis dua thiab cov qauv sab saud txav thiab ua ke ntawm

siv conveyor thiab kev tswj hwm.

3. Qhov hnyav ntawm kev tuag tau qhib thiab kaw thiab kaw los ntawm kev txhawb nqa los ntawm daim ntawv kab rov tav. Qhov tshwm sim uas daim formwork tsis tuaj yeem qhib thiab kaw vim yog lub hauv ntej tsis sib xws los ntawm kev sib tsoo ntawm kev tuag zoo ib yam li lub tshuab kab rov tav yuav tsis tshwm sim. Nws pab kom tswj tau qhov tseeb ntawm cov tshuab thiab tuag.

4. Los ntawm kev siv dag yooj yim, txhua qhov kab noj hniav yas tau tawm tau, uas yog tsim rau precision molding.

3.Double txhaj tshuaj molding tshuab

Kev tuaj yeem ib zaug txhaj molding ob xim ntawm lub tshuab txhaj tshuaj molding, tuaj yeem ua tau raws li cov neeg siv khoom xav kom pom, tus neeg siv tuaj yeem siv cov khoom lag luam zoo dua.

4. Txhua fais txhaj tshuaj molding tshuab

Kev siv tshuab hluav taws xob txhaj moulding tshuab tsis tuaj yeem tsuas yog ua tau raws li qhov xav tau ntawm cov ntawv thov tshwj xeeb, tab sis kuj muaj ntau qhov zoo dua li kev txhaj tshuaj molding tshuab ua ke.

Lwm qhov zoo dua ntawm lub tshuab hluav taws xob txhaj tshuaj tag nrho yog tias nws txo cov suab nrov, uas tsis tsuas yog pab cov neeg ua haujlwm, tab sis tseem txo qis peev hauv cov khoom pov thawj cov khoom lag luam.

5.Angle txhaj tshuaj molding tshuab

Lub axis ntawm kev txhaj tshuaj ntsia hlau ntawm lub kaum sab xis txhaj tshuaj moulding tshuab yog txiav mus rau qhov txav txav ntawm clamping mechanism template, thiab nws qhov zoo thiab qhov tsis zoo yog nyob nruab nrab ntawm ntsug thiab kab rov tav. Vim tias txoj kev txhaj tshuaj thiab moulding qhov chaw yog nyob rau tib lub dav hlau, lub tshuab txhaj tshuaj angular yog qhov tsim nyog rau cov pwm nrog asymmetrical geometry ntawm sab rooj vag lossis cov khoom lag luam uas qhov chaw moulding tsis tso cai cim rooj vag.

6.Multi chaw nres tsheb moulding tshuab

Cov cuab yeej txhaj tshuaj thiab cov cuab yeej clamping muaj ob lossis ntau dua haujlwm ua haujlwm, thiab cov cuab yeej txhaj tshuaj thiab lub tshuab clamping tuaj yeem npaj ntau txoj kev.

Tam sim no, peb hom kev txhaj tshuaj molding tshuab yog dav siv:

Kab rov tav txhaj moulding tshuab yog siv dav vim nws qhov chaw me me, kev yooj yim txhim kho thiab ntau daim ntawv thov ntau yam. Ob chav txhaj moulding tshuab feem ntau yog siv rau kev sib khi thiab cov dej tsis txawv ntawm cov khoom siv hluav taws xob, kev poob siab rau cov cuab yeej hluav taws xob, thiab cov khoom lag luam nrog ntau yam xim thiab cov qauv compact. Txhua tshuab hluav taws xob txhaj moulding tshuab siv rau hauv kev tsim cov xaj loj, siab raug me me thiab nruab nrab qhov loj me.

II-Ua li cas kev txhaj tshuaj yas txhaj tshuaj ua haujlwm?

Txoj cai ua haujlwm ntawm kev txhaj tshuaj molding tshuab yog zoo ib yam li qhov uas txhaj koob txhaj tshuaj. Nws yog cov txheej txheem thev naus laus zis ntawm cov tshuaj txhaj tshuaj txhaj tshuaj yas (txhais tau tias ntws) mus rau hauv cov kab noj hniav kaw los ntawm txhais tau tias lub zog ntawm cov ntsia hlau (lossis plunger) thiab tau txais cov khoom tom qab kho.

Kev txhaj tshuaj molding yog txheej txheem kev puag ncig, txhua lub voj voog feem ntau suav nrog:

Kev muaj txiaj ntsig ntawm kev pub mis - melting plasticization - siab txhaj - txias - pwm qhib thiab coj qhov chaw. Tshem cov ntu yas thiab tom qab ntawd kaw lub pwm rau lub voj voog tom ntej.

Kev txhaj tshuaj molding tshuab ua haujlwm cov khoom: txhaj tshuaj moulding tshuab ua haujlwm cov khoom muaj xws li tswj cov haujlwm ua haujlwm, kev tswj hluav taws xob tswj kev ua haujlwm thiab kev ua haujlwm hydraulic haujlwm ntawm peb yam. Kev xaiv ntawm cov txheej txheem txhaj tshuaj tiv thaiv kev ua, kev qoj ib ce, kev txhaj tshuaj siab, kev txhaj tshuaj nrawm, hom kev tawm, ntsuas qhov ntsuas kub ntawm txhua seem ntawm lub thoob, txhaj tshuaj siab thiab nraub qaum siab hloov kho tau ua raws feem.

Cov txheej txheem dav dav ntawm cov ntsia hlau txhaj moulding tshuab yog: ua ntej, granular lossis hmoov yas ntxiv rau hauv lub thoob, thiab cov yas yaj tau yaj los ntawm kev sib hloov ntawm cov ntsia hlau thiab cov cua kub ntawm chim sab nraud phab ntsa. Tom qab ntawd lub tshuab ua lub pwm thiab lub rooj zaum txhaj tshuaj txav mus rau pem hauv ntej, kom lub pob hluav taws xob ze rau ntawm lub qhov rooj ntawm lub pwm, thiab tom qab ntawd cov roj siab los tso rau hauv lub tog raj kheej txhaj ua rau ntsia hlau. Cov pas nrig tau thawb mus tom ntej kom cov yaj tau txhaj rau hauv qhov tuag kaw nrog qhov kub ntawm qhov ntsuas ntawm qhov ntsuas siab thiab cua siab. Tom qab qee lub sijhawm thiab nias siab (tseem hu ua tuav lub zog) thiab cua txias, lub suab yaj yuav sib xyaw thiab pwm, thiab cov khoom tuaj yeem tawm (lub hom phiaj ntawm tuav siab yog tiv thaiv qhov reflux ntawm yaj nyob rau hauv cov kab noj hniav thiab kom muab cov khoom siv mus rau qhov kab noj hniav.Thiab kom ntseeg tau tias cov khoom lag luam muaj qee qhov ceev thiab qhov ntev tau txais kev pom zoo.Qhov qhov yooj yim ntawm kev txhaj tshuaj molding yog plasticization, txhaj tshuaj thiab molding. Yas yog qhov ua kom tiav thiab ua kom zoo ntawm cov khoom lag luam molding, thiab txhawm rau ua kom tau raws li kev txhaj tshuaj moulding, kev txhaj tshuaj yuav tsum muaj kev tiv thaiv txaus thiab nrawm.Qhov tib lub sijhawm, vim hais tias kev txhaj tshuaj siab yog siab heev, sib piv mus rau qhov chaw siab nyob rau hauv cov kab noj hniav (qhov nruab nrab siab nyob rau hauv cov kab noj hniav feem ntau yog 20 thiab 45) MPa), yog li yuav tsum muaj lub zog clamping txaus .Nws tuaj yeem pom tias cov cuab yeej txhaj tshuaj thiab cov khoom siv clamping yog qhov tseem ceeb ntawm kev txhaj tshuaj molding tshuab.

Kev ntsuas qhov tseeb ntawm cov khoom yas yog suav nrog peb yam: thawj zaug yog qhov zoo li lub ntsej muag, suav nrog kev ntseeg siab, xim, luster, thiab lwm yam; qhov thib ob yog qhov tseeb ntawm qhov loj me thiab thaj chaw txheeb ze; qhov peb yog cov khoom siv lub cev, tshuaj thiab hluav taws xob sib xyaw rau kev siv. Cov kev xav tau zoo no kuj txawv raws ntau zaus ntawm cov khoom. Qhov tsis xws ntawm cov khoom feem ntau yog nyob rau hauv tus qauv tsim, qhov tseeb thiab hnav degree ntawm pwm. Tab sis qhov tseeb, cov kws kho nyob rau hauv cov yas ua cov khoom lag luam feem ntau raug kev txom nyem los ntawm cov teeb meem nyuaj ntawm kev siv thev naus laus zis los kho cov teeb meem tshwm sim los ntawm pwm tsis xws luag thiab muaj cov nyhuv me.

Kev hloov kho ntawm cov txheej txheem yog txoj hauv kev tsim nyog los txhim kho cov khoom ua tau zoo thiab tsim tawm. Vim hais tias qhov kev txhaj tshuaj nws tus kheej luv heev,

yog tias cov txheej txheem cov txheej txheem tsis zoo tswj, cov khoom pov tseg yuav ntws txuas ntxiv. Thaum kho cov txheej txheem, nws yog qhov zoo uas yuav tau hloov ib qho kev mob rau ib zaug thiab saib nws ob peb zaug. Yog tias qhov siab, kub thiab sijhawm tsis sib sau thiab kho, nws yooj yim ua rau muaj kev kub ntxhov thiab nkag siab. Muaj ntau txoj hauv kev thiab txhais tau tias yuav kho cov txheej txheem. Piv txwv li, muaj ntau tshaj kaum qhov kev daws teeb meem rau qhov teeb meem tsis txaus siab ntawm kev txhaj tshuaj ntawm cov khoom lag luam. Tsuas yog los ntawm xaiv ib lossis ob lub ntsiab tseem ceeb los daws qhov teebmeem ntawm kev daws teeb meem tuaj yeem peb daws qhov teeb meem. Ntxiv rau qhov no, peb kuj yuav tsum xyuam xim rau kev sib txuas lus zoo nyob hauv kev daws teeb meem. Piv txwv li: cov khoom lag luam muaj kev nyuaj siab, qee zaum nce cov khoom kub, qee zaum kom txo cov khoom kub; qee zaum kom nce qhov ntau ntawm cov khoom, qee zaum kom txo qis ntawm cov khoom. Pom txog lub peev xwm ntawm kev daws qhov teeb meem nrog kev ntsuas rov qab.

III-Lub ntsiab kev ntsuas ntawm kev txhaj tshuaj moulding tshuab yog

Kaw quab yuam, qhov siab tshaj qhov txhaj tshuaj, qhov siab tshaj plaws thiab tsawg kawg tuag thickness, pwm hloov stroke, qhov deb ntawm rub pas nrig, ejection stroke thiab ejection siab, thiab lwm yam.

Cov kev cai hauv kev txhaj tshuaj molding tshuab uas tsim nyog rau kev txhaj tshuaj molding tuaj yeem xaiv raws li hauv qab no:

1 Clamping quab yuam: cov khoom kwv yees cheeb tsam sib npaug ntawm cov pwm kab noj hniav kom tsawg dua clamping quab yuam, P yog sib npaug lossis sib npaug QF kab noj hniav siab;

2 Kev txhaj tshuaj ntau tshaj plaws: cov khoom hnyav <qhov siab tshaj txhaj tshuaj. Cov khoom hnyav = qhov txhaj tshuaj ntau tshaj plaws * 75 ~ 85%.

3 Kev txhaj tshuaj moulding tshuab mould thickness: qhov sib nrug ntawm qhov siab tshaj plaws thiab yam tsawg kawg nkaus tus nqi txhaj tshuaj molding tshuab thiab ob lub ntsiab lus. Pwm qhov siab tuab txhaj tshuaj molding tshuab tsawg tshaj li qhov siab tshaj plaws pwm tuab pwm. Qhov tsawg kawg nkaus tuab yog sib npaug rau qhov pwm tsawg kawg nkaus ntawm kev txhaj tshuaj moulding tshuab.

4 Pwm stroke: pwm qhib qhov nrug = pwm tuab + khoom qhov siab + qhov nrug deb + thaj tsam khoom. Ntawd yog hais, pwm-nyob deb li cas.

5 Qhov kev ncua deb ntawm cov pas nrig: uas yog los txhawm rau tsim pwm chaw; pwm qhov ntev * qhov dav yog tsawg dua qhov rub tus pas nrig nyob deb.

6 Ejection stroke thiab siab: cov khoom lag luam tawm ntawm qhov siab thiab siab <ejection stroke thiab siab ntawm kev txhaj tshuaj molding tshuab.

Lub kaw lus thiab muaj pes tsawg leeg txhaj tshuaj tshuab

Kev txhaj tshuaj molding tshuab feem ntau muaj kev txhaj tshuaj kaw lus, pwm kaw qhov system, kaw lus kis kab mob, kaw lus tswj hluav taws xob, roj system, cua sov thiab cua txias system, xyuas kev nyab xeeb thiab lwm yam.

Kev txhaj tshuaj system

Kev ua haujlwm ntawm kev txhaj tshuaj: Lub kaw lus txhaj tshuaj yog ib qho tseem ceeb tshaj plaws ntawm kev txhaj tshuaj molding tshuab, feem ntau muaj peb hom qauv plunger, ntsia hlau, ntsia hlau ua ntej txhaj yas plunger kev txhaj tshuaj. Kev siv ntau hom yog ntsia hlau. Nws txoj haujlwm yog hno molten yas rau hauv cov kab noj hniav los ntawm cov ntsia hlau los ntawm qee qhov siab thiab nrawm tom qab plasticizing ib qhov nqi ntawm cov yas hauv lub sijhawm teev hauv lub voj voog ntawm lub tshuab txhaj. Tom qab txhaj tshuaj, cov yaj tau txhaj rau hauv cov pwm kab noj hniav tau tuav ruaj khov.

Kev txhaj tshuaj muaj cov cuab yeej siv yas thiab lub zog hloov ua haujlwm.

Cov cuab yeej plasticizing ntawm cov ntsia hlau txhaj tshuaj molding tshuab yog tsuas yog tsim los ntawm kev pub zaub mov, cov kav dej, ntsia hlau, kua nplaum hla cov khoom siv thiab nozzle. Cov khoom siv fais fab kis nrog rau lub tog raj kheej txhaj tshuaj, lub tog raj kheej txav ntawm lub khob txhaj tshuaj thiab lub hau tsav ntsia hlau (a

Pwm tshuab clamping

Txoj haujlwm ntawm clamping system: txoj haujlwm ntawm clamping system yog kom ntseeg tau pwm kaw, qhib thiab tawm khoom. Nyob rau tib lub sijhawm, tom qab lub pwm raug kaw, txaus clamping lub zog nkag los tiv thaiv lub siab ntawm cov pwm kab noj los ntawm cov yas melted nkag mus rau hauv cov pwm kab noj hniav, thiab pwm pwm thaiv tau tiv thaiv, uas ua rau cov xwm txheej tsis zoo ntawm cov khoom.

Kev sib xyaw ntawm cov kab ke clamping: cov tshuab clamping feem ntau yog los ntawm cov khoom siv clamping, dai tshuab, kho kev hloov kho, ejecting mechanism, ua ntej thiab rov qab tsim cov qauv, txav lub ntsej muag, clamping lub tog raj kheej thiab kev tiv thaiv kev nyab xeeb mechanism.

Kev kaw lus hydraulic

Kev ua haujlwm ntawm qhov hydraulic kis tau txais yog muab lub zog rau kev txhaj tshuaj moulding tshuab raws li ntau yam kev ua tiav raws li cov txheej txheem, thiab kom ua tiav cov kev xav ntawm qhov siab, qhov nrawm thiab qhov kub thiab txias uas xav tau los ntawm ntau qhov chaw ntawm kev txhaj tshuaj molding tshuab. Nws yog tsuas yog tsim ntawm ntau yam hydraulic thiab cov khoom siv sib xyaw hydraulic, nyob rau hauv uas cov roj twj tso kua mis thiab lub cev muaj zog yog lub zog qhov hluav taws xob ntawm kev txhaj tshuaj molding tshuab. Ntau yam li qub tswj cov roj siab thiab txaus tus nqi, thiaj li ua kom tau raws li qhov yuav tsum tau ua ntawm cov txheej txheem txhaj tshuaj molding txheej txheem.

Kev tswj hwm hluav taws xob

Qhov kev sib koom tes tsim nyog ntawm lub kaw hluav taws xob thiab lub kaw lus hydraulic tuaj yeem paub cov txheej txheem cov txheej txheem (siab, ntsuas kub, nrawm nrawm, lub sijhawm) thiab ntau yam kev ua haujlwm ntawm lub tshuab txhaj tshuaj. Nws yog tsuas yog tsim cov khoom siv hluav taws xob, khoom siv hluav taws xob, twj paj nruag (saib hauv qab sab xis), cua sov, lub teeb thiab lwm yam. Feem ntau, muaj plaub txoj hauv kev tswj, phau ntawv, semi-automatic, automatic thiab kho.

Cua sov / cua txias tsim

Cov cua sov siv los ua cua sov lub thoob thiab qhov txhaj tshuaj tsis siv ntsej muag. Cov kab hluav taws xob ntawm lub tshuab txhaj tshuaj feem ntau siv lub tshuab hluav taws xob cua sov uas yog cov cuab yeej siv cua sov, uas yog ntsia sab nraum lub thoob thiab sib cais los ntawm tus pas ntsuas kub. Thaum tshav kub kub muab hluav taws xob rau cov khoom siv hluav taws xob los ntawm kev siv cov raj cua sov ua kom sib luag; cua txias system yog tsuas yog siv los txias roj kub, qhov ntsuas kub siab dhau los ntawm roj yuav ua rau muaj ntau yam kev txhaum, yog li cov roj kub yuav tsum raug tswj. Lwm qhov chaw yuav tsum tau txias yog nyob ze qhov chaw nres nkoj tawm ntawm lub tshuab raj kom pub kom tiv thaiv cov khoom raw ntawm yaj ntawm qhov chaw nres nkoj tawm, uas ua rau cov khoom noj tsis tuaj yeem ua kom zoo.

Lub cev kaw lus

Lub tshuab roj kaw hluav taws xob yog lub Circuit Court uas muab cov khoom siv roj lubrication rau tus txheeb ze txav chaw ntawm kev txhaj tshuaj moulding tshuab, xws li txav cov qauv, hloov kho lub cuab yeej, txuas txuas lub pob khawm thiab tua cov lus, thiaj li txo qis siv zog thiab txhim kho lub neej ntawm qhov chaw. Lub tshuab ua kom lub tshuab nqus tau ua tau tshuab kev sib nqus tsis so lossis tsis siv neeg lub tshuab hluav taws xob tsis siv neeg.

Kev saib xyuas kev nyab xeeb

Cov cuab yeej kev nyab xeeb ntawm txhaj tshuaj moulding tshuab yog siv rau kev tiv thaiv tib neeg thiab tshuab kev nyab xeeb. Qhov tseem ceeb los ntawm lub qhov rooj muaj kev nyab xeeb, kev nyab xeeb baffle, hydraulic valve, txwv hloov, photoelectric kuaj pom thiab lwm yam, kom ua tiav hluav taws xob - Mechanical - hydraulic thaiv kev tiv thaiv.

Kev soj ntsuam kab ke saib xyuas cov roj kub, cov khoom kub, qhov system tshaj, cov txheej txheem thiab cov khoom siv tsis ua tiav ntawm lub tshuab txhaj tshuaj, thiab qhia lossis ceeb toom rau qhov xwm txheej tsis meej.

Mestech nruab 30 teeb txhaj tshuaj molding tshuab npog 100 tons rau 1500 tons, peb tuaj yeem tsim cov khoom yas los ntawm 0.50 grams mus rau 5 kg ntawm yas seem ntawm ntau qhov ntau thiab tsawg. Yog tias koj muaj cov khoom lag luam yas uas xav tau txhaj tshuaj moulding, thov hu rau peb