Nylon ntu txhaj tshuaj molding

Cov lus piav qhia luv luv:

Nylon ntu txhaj tshuaj molding yog feem ntau siv rau kev tsim cov khoom vaj khoom tsev. Cov khoom hluav taws xob tau siv dav hauv tsheb, khoom siv hluav taws xob, kev sib txuas lus, hluav taws xob.

MESTECH muaj cov kev txhaj tshuaj moulding machinery yog qhov loj los ntawm 90 txog 1200 tons, cia peb ua cov nylon yas qhov chaw ntawm ntau qhov ntau thiab tsawg thiab cov nplai. Peb zoo siab los tham txog nylon txhaj tshuaj molding cov tswv yim thiab kev daws teeb meem nrog txhua tus neeg kom ntseeg tau tias cov txheej txheem thiab cov khoom siv yog qhov haum rau koj txoj haujlwm.

Nylon txhaj tshuaj molding qhov chaw tau siv nyob rau ntau qhov chaw vim lawv cov khoom siv zoo heev, xws li cov iav pulleys, lub log, cov khoom siv hluav taws xob ntau, cov khoom siv ib puag ncig cryogenic, cov khoom siv ultrasonic ib puag ncig, ntxiv rau hloov cov hlau qhov chaw thiab txhuas qhov chaw rau tshuab thiab khoom siv niaj hnub.

Dab tsi yog nylon txhaj moulded qhov siv rau?

Cov khoom siv nylon yog siv nyob rau hauv ntau qhov sib txawv ntawm cov ntawv thov kev lag luam sib txawv vim nws muaj cov yam ntxwv zoo thiab cov khoom siv hluav taws xob, zoo tshaj plaws hauv tawv, hnav tsis kam thiab tshuaj lom neeg tsis kam. Nylon txhaj tshuaj molding tsim cov khoom yas uas yog siv rau hauv kev lag luam suav tsis txheeb thiab kev siv, xws li:

Cov neeg siv khaub ncaws thiab khau

Cov kev ua si kis las thiab khoom ua si

Muaj cov khoom lag luam

Cov khoom kho mob

Automotive cov khoom

Nylon yog siv rau ntau qhov kev siv los suav nrog kev hnav khaub ncaws, txhawb ntxiv rau hauv cov khoom siv roj hmab zoo li lub log tsheb, rau siv siv txoj hlua lossis xov, thiab siv rau ntau qhov kev txhaj tshuaj pwm rau cov tsheb thiab cov khoom siv kho tshuab. Nws yog qhov tshwj xeeb muaj zog, tsis kam tiv thaiv kev puas tsuaj thiab noo noo nqus, ntev ntev, tiv taus cov tshuaj, ywj thiab yooj yim los ntxuav. Nylon feem ntau yog siv los hloov cov hlau uas tsis muaj zog me. Nws yog cov yas ntawm kev xaiv rau cov khoom siv hauv lub cav sib xyaw ntawm cov tsheb vim nws lub zog, qhov kub thiab txias, thiab tshuaj lom neeg tau zoo.

Raws li nylon tau zoo khoov lub zog, nws qiv nws tus kheej zoo rau qhov chaw uas yuav muab khoom ntsaws. Tsis tas li ntawd, nrog lub siab hnav tsis kam thiab coefficient tsawg ntawm kev sib txhuam, nylon ua haujlwm tau zoo hauv cov ntawv thov xws li swb, kabmob thiab txhua yam cuab yeej uas tau muab los ntawm cov lus tsa suab.

Nylon PA66 iav

Sab hauv xov nylon npog

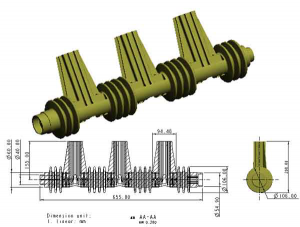

High voltage nylon hloov ncej

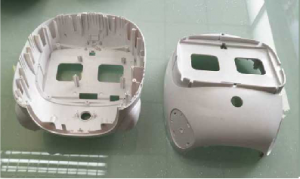

Lub tsho ntev ntev rau hluav taws xob

Nylon Doorknob

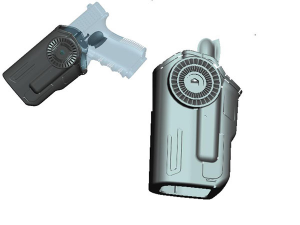

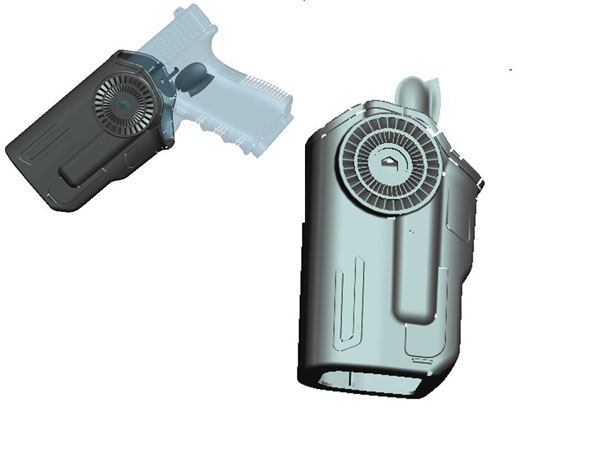

Nylon holster pister npog

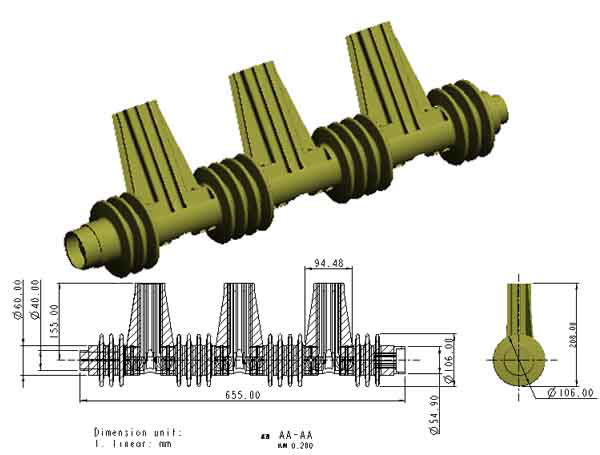

Nylon qhia pulley

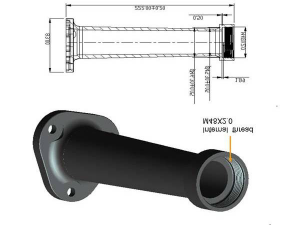

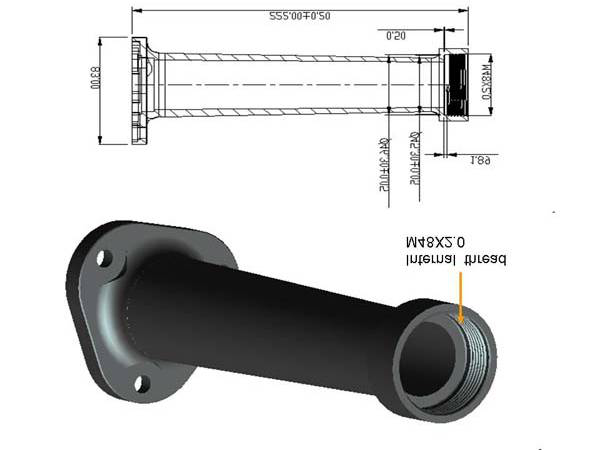

Lub tsheb nqus pa tawm

Dab tsi yog qhov sib txawv ntawm ntau hom Nylon

Hauv lub caij nyoog niaj hnub no nws tau tsim los ntawm cov lag luam coob, txhua tus nrog lawv cov txheej txheem ntau lawm, cov qauv tsis sib xws, thiab cov npe lag luam. Koj tuaj yeem pom tag nrho cov npe ntawm cov khoom lag luam nyob ntawm no.

Cov kev hloov pauv uas nquag muaj xws li Nylon 6, Nylon 6/6, Nylon 66, thiab Nylon 6/66. Cov naj npawb qhia txog cov naj npawb ntawm carbon atoms ntawm acid thiab amine pawg. Ib tus lej (nyiam“6”) taw qhia tias cov khoom raug teeb tsa los ntawm ib qho monomer hauv kev sib xyaw ua ke nrog nws tus kheej (piv txwv li cov qauv ntawm ib hom yog ib homopolymer). Ob tug lej (nyiam“66”) taw qhia tias cov khoom raug cais los ntawm ntau tus monomers hauv kev sib xyaw ua ke nrog (sib xyaw ua ke). Lub pob zeb qhia tias cov khoom tsim los ntawm cov sib txawv hauv pawg sib xyaw hauv kev sib xyaw ua ke (piv txwv li nws yog tus kws lij choj).

Nylon tseem tuaj yeem ua ke nrog ntau ntau ntawm cov khoom sib ntxiv los tsim cov sib txawv nrog cov khoom sib txawv sib txawv.

Koj puas paub cov lus qhia rau kev txhaj tshuaj molding nylon?

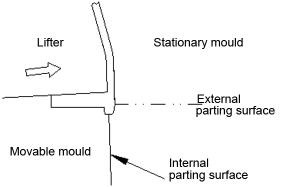

(1) .Txoj kev tsim ntawm phab ntsa lossis tav

Nylon muaj lub siab ntsws thiab muaj lub siab tuab ntawm phab ntsa tuab ntawm qhov chaw. Ntawm qhov ua ntej lav txog cov khoom ntawm cov khoom, phab ntsa tuab yuav tsum me npaum li sai tau. Cov khoom tuab yog, qhov loj dua qhov shrinkage yog, thiab lub zog tsis txaus, yog li cov cuab yeej txhawb nqa tuaj yeem ntxiv.

(2) .De lub kaum sab xis

High shrinkage, yooj yim demoulding, cua ntsawj ntshab kaum sab xis ntawm demoulding yuav ua tau 40 ′ -1゜40′

(3) .Ntseeg

Qhov thermal expansion coefficient ntawm nylon yog 9-10 zaug loj dua li ntawm cov hlau thiab 4-5 npaug loj dua li ntawm txhuas. Cov ntawv hlau ntxeem tau cuam tshuam nrog kev ntog ntawm nylon thiab ua rau muaj kev nyuaj siab ntau dua, uas tuaj yeem ua rau kom tawg. Nws yog qhov yuav tsum tau hais tias qhov tuab ib ncig ntawm qhov ntxig yuav tsum tsis pub tsawg dua ntawm txoj kab uas hla ntawm cov hlau ntxig.

(4) .Hygroscopicity

Nylon yog yooj yim kom nqus noo noo thiab yuav tsum tau ziab ua ntej sib sau.

(5) .Qhov cua tshuab tawm

Nylon tsis muaj viscosity tsawg, thiab sau cov pwm sai sai thaum muaj kev txhaj tshuaj siab. Yog tias cov pa roj tsis tuaj yeem tawm hauv lub sijhawm, cov khoom lag luam yog cov huab cua ua pa, kub hnyiab thiab lwm yam tsis xws luag. Tus neeg tuag yuav tsum muaj qhov lossis muaj qhov pa tawm ntawm cov pa, uas feem ntau qhib tawm ntawm lub rooj vag. Qhov txoj kab uas hla ntawm lub qhov hluav taws xob tso tawm yog_1.5-1 hli, thiab qhov tob ntawm lub qhov hluav taws xob sib txawv yog tsawg dua 0.03 hli

Mestech tau cog lus los txhaj tshuaj txhaj pwm thiab txhaj tshuaj molding kev tsim cov nylon qhov chaw rau cov neeg siv khoom. Thov koj xav tiv tauj peb yog tias koj xav tau tam sim no ntxiv.