Pwm chaw tsim tshuaj paus thiab cov chaw muab tshuaj, Suav

Mestech tau tsim muaj nyob rau xyoo 2009, nyob hauv nroog Shenzhen, lub chaw tsim khoom lag luam nyob rau sab qab teb Suav. Mestech tau cog lus rau pwm tsim khoom lag luam thiab yas ua yas moulding. Tam sim no peb ntev peb cov kev pabcuam rau cov khoom tsim, hlau tuag casting, stamping thiab machining. Peb tseem muab cov neeg siv khoom lag luam ib-nres los ntawm qhov chaw mus rau cov khoom sib dhos ua tiav.

Cov khoom siv yas thiab cov hlau thiab cov khoom lag luam peb tsim tau them rau ntau lub teb.Lawv nrog rau Kev Lag Luam, Kev Kho Mob, Electronics, Hluav Taws Xob, Hluav Taws Xob, Qhov Chaw Pib Khoom, Khoom Siv Hauv Tsev thiab Khoom Siv Khoom lag luam. Peb tsis tu ncua dhau los ntawm peb cov neeg siv cov kev cia siab los ntawm txhawb nqa txhua tus neeg koom nrog thiab tsim kab lis kev cai uas tuav txoj kev txhim kho, kev lag luam ntshiv thiab muab khoom-cov kev sib koom tes kom ntseeg tau tus nqi siab tshaj plaws rau peb cov neeg siv khoom.

Hoobkas tsev

Muaj peev xwm

Txij li thaum nws tsim, Mestech tau cog lus los muab cov qhua tuaj yeem nrog cov khoom lag luam zoo thiab muaj txiaj ntsig zoo. Peb muaj cov kws tshaj lij kev ua haujlwm ntawm engineers, lub cav zoo nruab thiab kev tswj hwm kev tswj hwm zoo. Peb pheej siv cov thev naus laus zis tshiab thiab kev tswj cov txheej txheem txhawm rau txhawm rau tsim cov kev lag luam yas pwm, kev txhaj tshuaj, kev siv hlau tuag, tsim cov khoom tsim thiab cov khoom sib dhos ua kom tau raws li qhov xav tau ntawm cov neeg siv khoom. Nrog ua lub zog, nws yog tsuas yog xav nyob rau hauv cov hauv qab no:

Peb cov kws ua haujlwm pab neeg

Peb cov kws tshaj lij muaj cov kev paub ntau hauv kev tsim thiab ua cov txheej txheem ntawm cov khoom seem ntawm cov yas, hlau qhov chaw thiab cov pwm. Lawv siv software los tsim cov pwm thiab cov khoom lag luam. Lawv muaj peev xwm muab cov qhua tuaj yeem tsim cov khoom lag luam, kev tshawb xyuas khoom lag luam, kev tshuaj xyuas kev pheej hmoo thiab cov kev daws teeb meem.

Mestech cov kws txawj tuaj yeem siv UG, PROE, Moldflow thiab lwm yam software rau cov pwm tsim thiab tsom xam. Cov pwm peb ua npog pib tsheb, khoom siv kho mob, khoom siv hluav taws xob, khoom siv hauv tsev, khoom siv hluav taws xob, kev tiv thaiv ib puag ncig thiab khoom siv txhua hnub. Peb muaj peev xwm tsim thiab tsim HASCO thiab DEM txheem pwm raws li cov neeg siv khoom kom ua raws li, thiab xa tawm mus rau lwm lub teb chaws thiab cheeb tsam.

Mestech cov kws ua haujlwm tuaj yeem ua haujlwm nrog cov neeg siv khoom lag luam los muab cov yas tsim thiab cov qauv hlau tsim cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, thiab ua qhov kev tshuaj xyuas tau zoo, sib tham thiab nrhiav teeb meem thiab muab cov lus qhia txhim kho, ntxiv rau pwm tsim thiab tsim khoom hauv cov theem hauv qab no.

Peb muaj cov pab pawg engineering, lawv ua cov khoom lag luam tsim thiab pwm tsim thiab qhov project ua raws kev soj qab. Yog tias koj muaj qhov project tshiab hauv koj txhais tes uas xav tau txhim kho cov pwm yas thiab txhaj tshuaj pwm qhov chaw, thov hu rau peb pab pawg tshaj lij, peb yuav tshuaj xyuas koj cov ntaub ntawv thiab xa qee qhov kev tawm tswv yim kom ua kom zoo rau koj cov qauv tsim, qhov no yuav ua kom paub tseeb tias koj qhov project yuav kev ua tiav zoo thaum lub sijhawm ua pwm thiab txuag ntau lub sijhawm rau kev ua pwm.

Peb lub Hoobkas thiab cov khoom siv sib txig sib luag

Pwm thiab kev txhaj tshuaj molding li ua hlau tuag casting yog kev cuam tshuam zoo rau cov qib ntawm cov khoom siv.

Pwm Rhiav

Hauv cov pwm rhiav, ntxiv rau cov kws tshaj lij kev tsim qauv, cov txheej txheem engineers thiab masters masters, peb lub tuam txhab ua raws nraim li cov txheej txheem kev siv tshuab tam sim no, nruab nrog advanced CNC tshuab cov cuab yeej, EDM txim tsim cov tshuab, hlau txiav tshuab cuab yeej. Kev ua haujlwm nrawm ntawm peb lub tshuab siab ceev CNC tshuab pab tuaj yeem ncav cuag 24000rpm.

Dua li ntawm hom pwm dav dav, peb tseem ua ob-xim txhaj pwm, teeb npias pwm thiab ntxig pwm, ua kom pom pwm, thiab ua cov pwm loj nyob hauv 3 meters.

Pwm Rhiav

Txhaj Rhiav

Nyob rau hauv cov nqe lus ntawm kev txhaj tshuaj molding, peb tau txhaj tshuaj molding tshuab los ntawm 100 tons txog 2000 tons, ob-xim txhaj tshuaj molding tshuab thiab hluav taws xob kev txhaj tshuaj molding tshuab. Ntxiv nrog rau kev txhaj tshuaj txhaj rau ntawm qhov loj me me yas qhov chaw, peb tuaj yeem tsim ob-xim yam, nyias-phab ntsa thiab qhov loj-loj. Cov khoom pwm tuaj yeem mus txog 1.5 metres ntev thiab qhov feem ntau ntawm cov tuab tuab tuaj yeem yog 0.50 hli

Peb muaj 32 lub tshuab txhaj tshuaj ntawm lub zog uas lub zog clamping khwv tau 90T ~ 2000T, tshuab ob leeg txhaj, nrog 50 ~ 60 tus neeg ua haujlwm. Muaj peev xwm ntau lawm 1.5 lab ntu hauv ib lub hlis.

Tuag nrum rhiav

Nyob hauv kev ua teb cov hlau, peb tuaj yeem muab kev tuag casting ntau lawm ntawm cov zinc alloy thiab aluminium alloy, ntxiv rau lub tshuab raug ua tau zoo ntawm qee qhov chaw hlau. (thov hu rau nplooj "hlau tuag casting" thiab "CNC machining" rau cov ntsiab lus.)

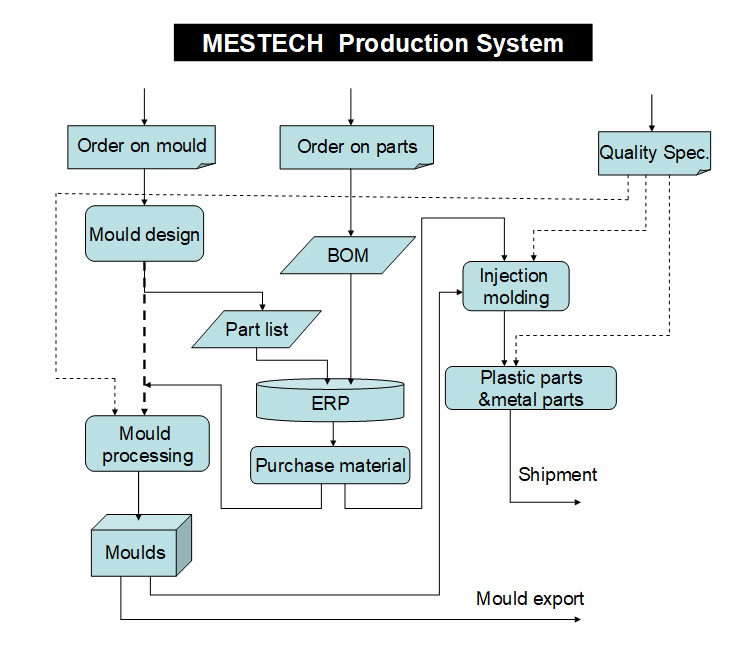

Kev tswj hwm kev tsim khoom zoo

Peb qhia cov phiaj xwm kev tswj hwm thiab ERP system hauv kev tsim khoom thiab txheej txheem. Raws li cov kev xav tau ntawm cov neeg siv khoom, peb ua lub sijhawm npaj thiab ua kom zoo dua qub los ntawm cov qauv tsim, cov khoom siv ua khoom siv mus rau kev tsim khoom, tsim khoom, tshuaj xyuas thiab xa tawm, thiaj li ua kom luv ntu kev tsim kho thiab txo tus nqi rau koj cov pwm thiab ntau lawm.

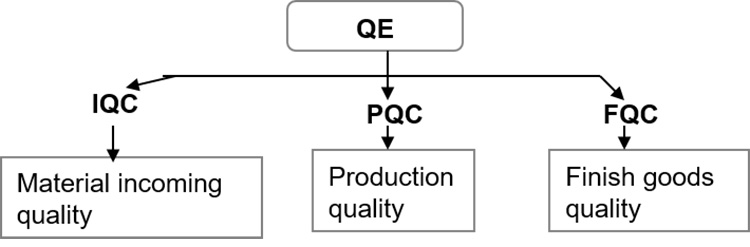

Peb qhov system zoo

Kev ua tau zoo yog tus cwj pwm tseem ceeb kom ntseeg tau tias qhov ua haujlwm ntawm cov khoom. Peb tau tsim txoj kev ua haujlwm zoo tshaj plaws thiab tsim cov txheej txheem ua tau zoo thiab cov qauv tsim kom ntseeg tau tias cov khoom tsim tawm ua tau raws li cov neeg yuav tsum tau ua, thiab ua kom paub tseeb tias cov khoom tsim tawm ntawm cov khoom tsim nyog rau cov neeg siv khoom. Xws li

Hauv cov pwm tsim theem, peb tau sim saib xyuas qhov zoo txij li lub pwm tsim

1. Cov ntaub ntawv tshawb xyuas ntawm cov neeg siv khoom xav tau

2. Mould tsim cov khoom siv coj los soj ntsuam

3. Kev sim pwm tsim

4. Pwm kev tsim qauv kawg

5. Tuaj tshuaj ntsuam ntawm pwm hlau

6. Tuag machining qhov ntev ntsuas

7. Kev ntsuas ntawm qhov ntsuas hluav taws xob loj

8. Pwm ntsuas thiab ntsuas

9. Kev sim khoom ntau lawm

Hauv theem tsim khoom

1. Kev lees paub ntawm cov khoom tsim nyog thiab cov qauv coj mus kuaj

2. Khoom lag luam ntau lawm thawj tsab xov xwm tshuaj ntsuam

3. Kev tshuaj xyuas ntau lawm

4. Tshawb xyuas tag nrho thiab pom qhov tseeb ntawm cov zaub mov xa tuaj

5. Kev ua tau zoo mus txog qhovtwg

Peb muaj cov pab pawg QC, thiab kuaj & ntsuas cov khoom siv: 3D Kev Ntsuas Qhov Nruab Nrab Tshuab thiab ntsuas xim.

Peb cov kws lag luam tawm kev tshaj lij

Mestech ua haujlwm nrog cov neeg koom tes los ntawm ntau lub teb chaws tau ntau xyoo, peb ua cov qauv pwm sib txawv thiab cov khoom lag luam rau lawv, nrog rau kev pabcuam ib-nres. Peb tau paub txog kev lag luam tawm txawv teb chaws. Lawv paub txog cov khoom thev naus laus zis thiab tuaj yeem sib tham txog kev tsim qauv, cov txheej txheem, kev ua lag luam thiab kev thauj khoom nrog koj ua lus Askiv. Lawv tuaj yeem nkag siab zoo txog koj cov kev xav tau thiab muab koj cov khoom lag luam thiab cov kev pabcuam tau raws sijhawm thiab raug.